Oca . 13, 2025 14:25

Back to list

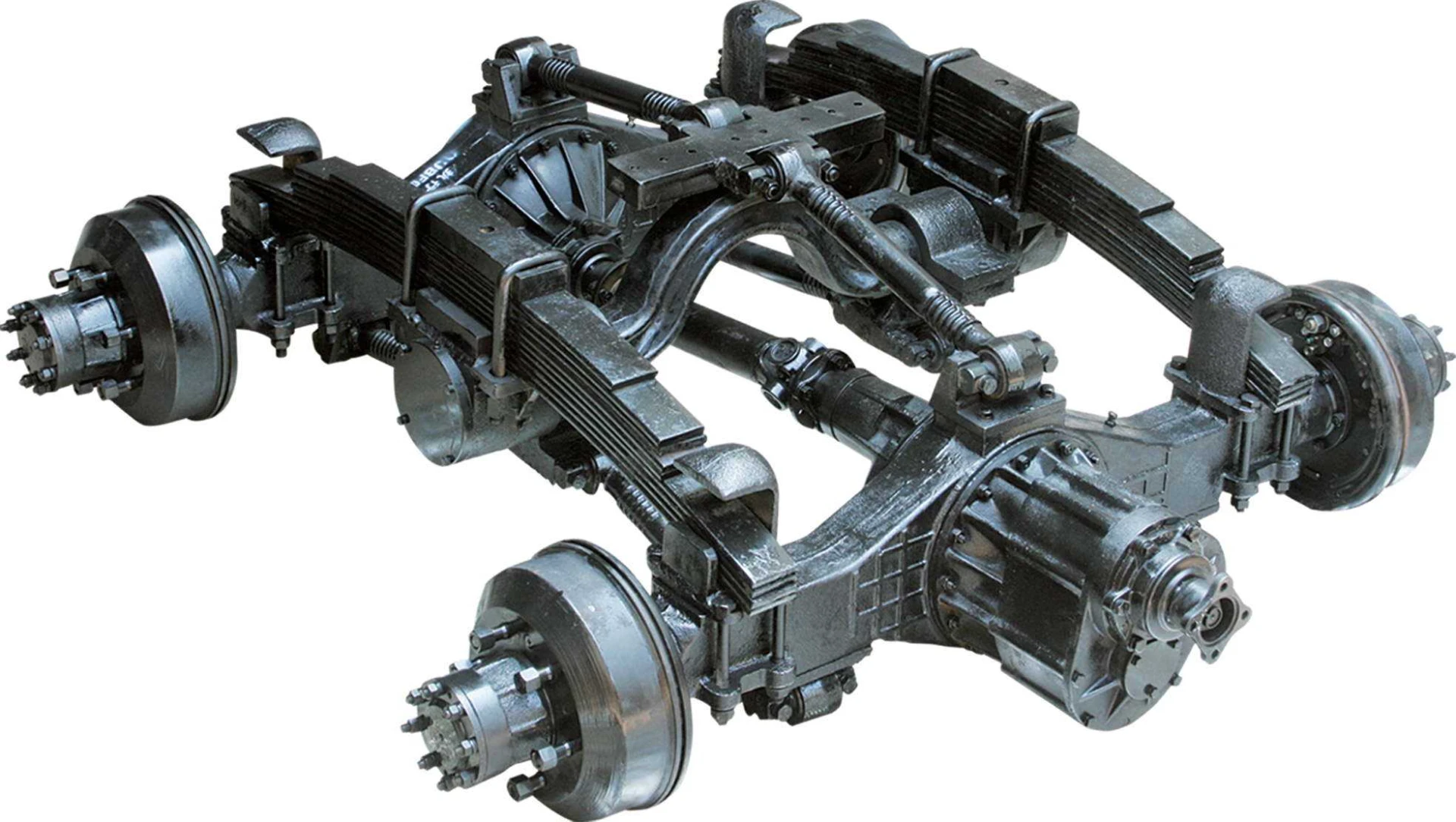

Oem Die-Cast Aluminium Parts

Aluminum cast parts play a pivotal role in numerous industries, revolutionizing the manufacturing processes by offering durability, lightweight properties, and cost-effectiveness. Within the automotive, aerospace, and consumer electronics domains, these parts have now become synonymous with high performance and reliability. This article delves deep into the unique advantages of aluminum cast parts, providing a rich perspective to engineers, manufacturers, and industry experts who seek to leverage these components for cutting-edge applications.

The recyclability of aluminum adds another layer of appeal to its casting processes. As companies across the globe strive for greener manufacturing practices, the ability to recycle and reuse aluminum cast parts eases the environmental burden. This sustainability factor improves corporate reputation and meets the growing demand for eco-friendly practices from consumers and regulatory bodies alike. Expertise in the domain of aluminum casting requires a nuanced understanding of both the material properties and the technological advancements in casting methods. As the technology evolves, the industry witnesses innovative techniques such as vacuum casting and rapid prototyping, which further extend the capabilities of aluminum casting. These advances allow for quicker turnaround times and prototypes that closely mimic the final product, enabling quicker market entry and feedback loops. Enhancing trustworthiness and authority in the field involves rigorous testing and compliance with international standards. Aluminum cast parts undergo meticulous quality checks, ensuring that they meet the industry's highest standards for performance and safety. Collaborations with leading testing institutes and adherence to global certifications are paramount for maintaining consumer confidence and upholding the exceptional reputation that the industry has built over the years. In conclusion, aluminum cast parts represent a confluence of engineering ingenuity, sustainability, and economical production. Their unparalleled properties continue to drive innovation, making them a cornerstone of modern manufacturing. For those in the field, leveraging the advantages of aluminum casting not only meets today's needs but also sets the stage for future technological advancements. Embracing these insights allows manufacturers and industries to harness the full potential of aluminum cast parts, ensuring their place at the forefront of engineering excellence and eco-friendly innovation.

The recyclability of aluminum adds another layer of appeal to its casting processes. As companies across the globe strive for greener manufacturing practices, the ability to recycle and reuse aluminum cast parts eases the environmental burden. This sustainability factor improves corporate reputation and meets the growing demand for eco-friendly practices from consumers and regulatory bodies alike. Expertise in the domain of aluminum casting requires a nuanced understanding of both the material properties and the technological advancements in casting methods. As the technology evolves, the industry witnesses innovative techniques such as vacuum casting and rapid prototyping, which further extend the capabilities of aluminum casting. These advances allow for quicker turnaround times and prototypes that closely mimic the final product, enabling quicker market entry and feedback loops. Enhancing trustworthiness and authority in the field involves rigorous testing and compliance with international standards. Aluminum cast parts undergo meticulous quality checks, ensuring that they meet the industry's highest standards for performance and safety. Collaborations with leading testing institutes and adherence to global certifications are paramount for maintaining consumer confidence and upholding the exceptional reputation that the industry has built over the years. In conclusion, aluminum cast parts represent a confluence of engineering ingenuity, sustainability, and economical production. Their unparalleled properties continue to drive innovation, making them a cornerstone of modern manufacturing. For those in the field, leveraging the advantages of aluminum casting not only meets today's needs but also sets the stage for future technological advancements. Embracing these insights allows manufacturers and industries to harness the full potential of aluminum cast parts, ensuring their place at the forefront of engineering excellence and eco-friendly innovation.

Latest news

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025

PRODUCTS CATEGORIES