Şub . 13, 2025 13:12

Back to list

china precision die casting

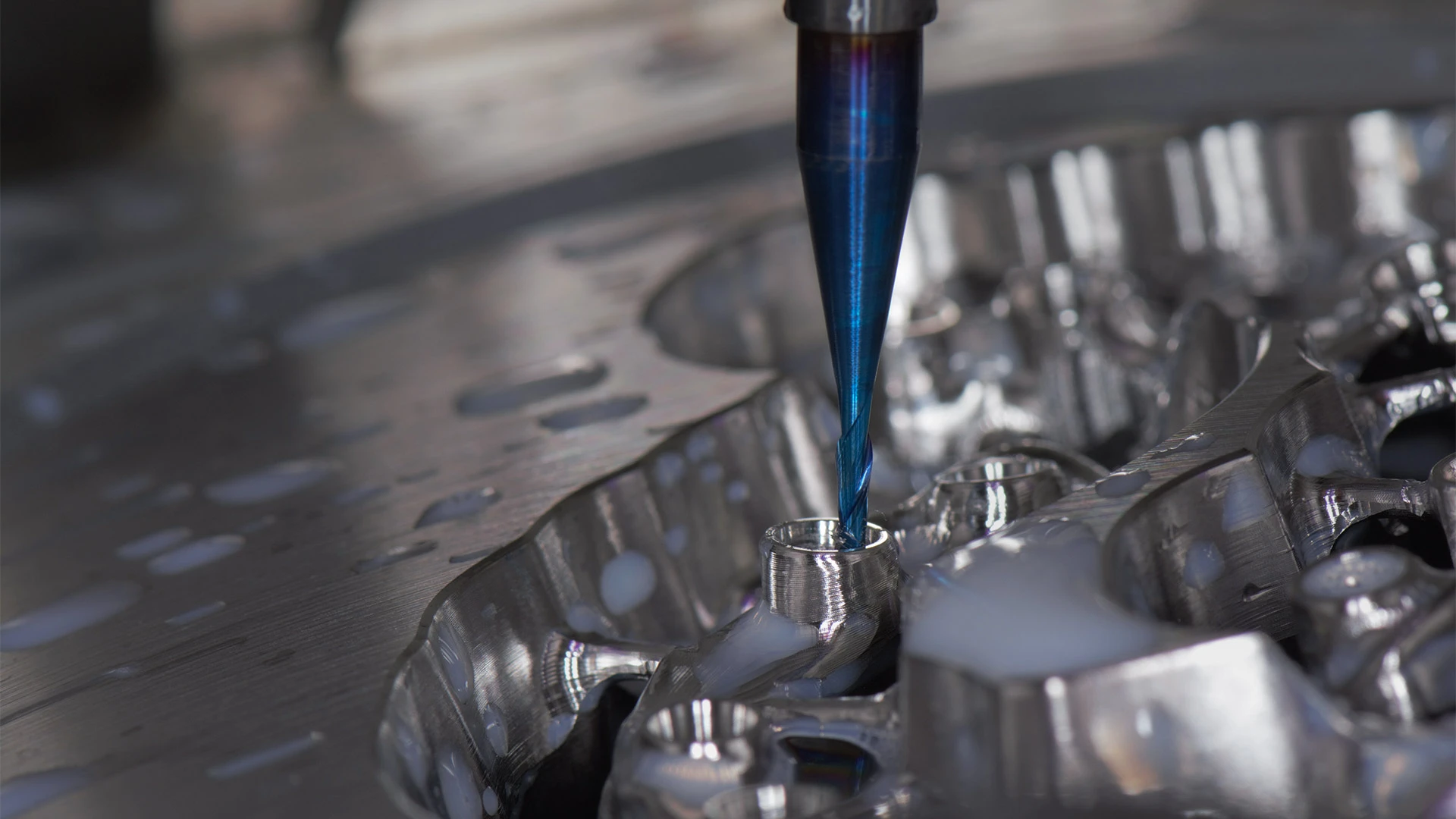

Copper die casting stands as a cornerstone in the manufacturing sector, embodying a blend of innovation, efficiency, and precision. The process entails injecting molten copper or copper alloys into mold cavities under high pressure, forming intricately detailed metal parts with remarkable accuracy. Copper's inherent properties—such as excellent thermal and electrical conductivity, superior corrosion resistance, and outstanding dimensional stability—make it an ideal choice for diverse applications across industries such as automotive, electronics, and telecommunications.

Moreover, the continuous innovations in copper die casting process technologies underscore the sector's dedication to excellence. Techniques such as vacuum die casting can further enhance the quality of the final product by reducing gas entrapment, leading to denser and stronger components. The development of copper alloys tailored for specific applications exemplifies the specialized knowledge and ongoing commitment to pushing the boundaries of what's possible with die casting technology. Professional expertise in copper die casting is not just about understanding the science behind the process but also encompasses adept project management and quality assurance. Leading manufacturers implement rigorous testing protocols at every stage of production to guarantee each component meets precise specifications and performance criteria. This includes non-destructive testing techniques such as X-ray inspection and thermal imaging, which ensure component integrity and reliability before leaving the production line. In summary, copper die casting remains unmatched in its ability to produce high-integrity, precision components for a range of applications. Its advantages in terms of thermal and electrical performance, coupled with the process's adaptability and efficiency, reinforce its role as a core manufacturing method. The continuous advancements in technology and material science contribute to the growth and enhancement of this field, demonstrating an unwavering commitment to quality and innovation. As industries evolve, the legacy and future of copper die casting continue to be defined by the meticulous expertise and reliability that mark its longstanding success.

Moreover, the continuous innovations in copper die casting process technologies underscore the sector's dedication to excellence. Techniques such as vacuum die casting can further enhance the quality of the final product by reducing gas entrapment, leading to denser and stronger components. The development of copper alloys tailored for specific applications exemplifies the specialized knowledge and ongoing commitment to pushing the boundaries of what's possible with die casting technology. Professional expertise in copper die casting is not just about understanding the science behind the process but also encompasses adept project management and quality assurance. Leading manufacturers implement rigorous testing protocols at every stage of production to guarantee each component meets precise specifications and performance criteria. This includes non-destructive testing techniques such as X-ray inspection and thermal imaging, which ensure component integrity and reliability before leaving the production line. In summary, copper die casting remains unmatched in its ability to produce high-integrity, precision components for a range of applications. Its advantages in terms of thermal and electrical performance, coupled with the process's adaptability and efficiency, reinforce its role as a core manufacturing method. The continuous advancements in technology and material science contribute to the growth and enhancement of this field, demonstrating an unwavering commitment to quality and innovation. As industries evolve, the legacy and future of copper die casting continue to be defined by the meticulous expertise and reliability that mark its longstanding success.

Latest news

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.07,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Customizable, Precision EngineeringNewsAug.07,2025

-

Sheet Metal Stamping Manufacturer | Custom Precision PartsNewsAug.07,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.07,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.07,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun|Customizable Casting&Fluid ControlNewsAug.06,2025

PRODUCTS CATEGORIES