jan . 15, 2025 01:20

Back to list

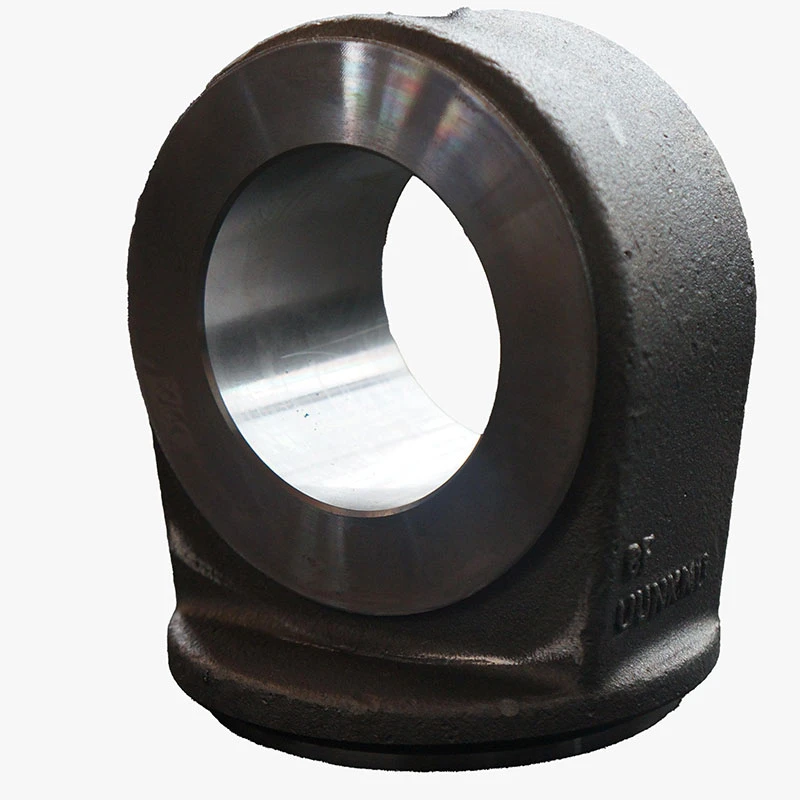

the casting

The casting process, a critical component of the manufacturing industry, has revolutionized how businesses conceptualize and produce products. With its roots steeped in ancient techniques, modern casting has undergone significant transformations to become what it is today—a highly technical and precise endeavor requiring a blend of craftsmanship and cutting-edge technology.

Trust is the cornerstone of the relationship between casting facilities and their clients. Transparency in the process, from initial design and prototyping to final production and quality assurance, fosters a collaborative environment. Clients must trust that their casting partners will deliver products that not only meet technical specifications but are also delivered on time and within budget constraints. Assurance of quality comes from adherence to strict quality control measures and certifications such as ISO standards, which provide consistency and reliability that clients can depend on. The casting process is continuously evolving, integrating technological advancements such as 3D printing and AI-driven quality inspection systems. These innovations promise to enhance precision, reduce waste, and expedite the production timeline, offering companies a competitive advantage in product development cycles. This evolution underscores the need for ongoing education and adaptation within the field, as both traditional expertise and new technologies play fundamental roles in advancing the industry. In conclusion, casting as a process is not only about pouring molten material into a mold but is a sophisticated blend of art and science. It demands a mastery that comes from experience, a depth of knowledge that arises from expertise, a reputation built on authority, and a foundational trust that guarantees product success. As the industry evolves, casting professionals will continue to be at the forefront, pushing the boundaries of innovation and quality in manufacturing.

Trust is the cornerstone of the relationship between casting facilities and their clients. Transparency in the process, from initial design and prototyping to final production and quality assurance, fosters a collaborative environment. Clients must trust that their casting partners will deliver products that not only meet technical specifications but are also delivered on time and within budget constraints. Assurance of quality comes from adherence to strict quality control measures and certifications such as ISO standards, which provide consistency and reliability that clients can depend on. The casting process is continuously evolving, integrating technological advancements such as 3D printing and AI-driven quality inspection systems. These innovations promise to enhance precision, reduce waste, and expedite the production timeline, offering companies a competitive advantage in product development cycles. This evolution underscores the need for ongoing education and adaptation within the field, as both traditional expertise and new technologies play fundamental roles in advancing the industry. In conclusion, casting as a process is not only about pouring molten material into a mold but is a sophisticated blend of art and science. It demands a mastery that comes from experience, a depth of knowledge that arises from expertise, a reputation built on authority, and a foundational trust that guarantees product success. As the industry evolves, casting professionals will continue to be at the forefront, pushing the boundaries of innovation and quality in manufacturing.

Next:

Latest news

-

Precision Casting AI Solution with GPT-4-Turbo | Optimized QualityNewsAug.02,2025

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

PRODUCTS CATEGORIES