jan . 13, 2025 17:27

Back to list

oem automotive parts manufacturers

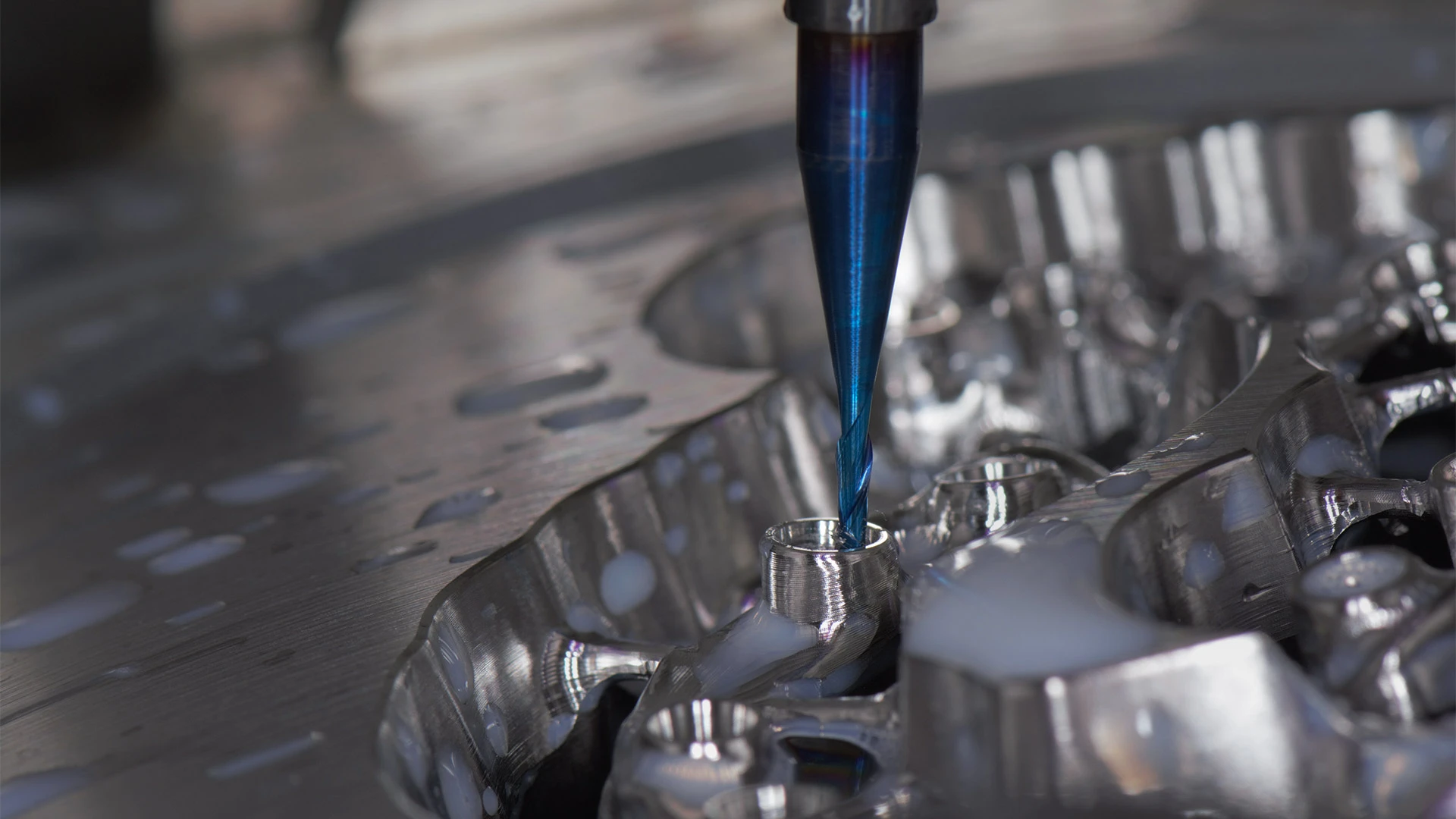

In the competitive realm of automotive manufacturing, casting automotive parts plays a pivotal role, blending tradition with cutting-edge innovation. Casting, an age-old technique, has evolved to meet the rigorous demands of modern automotive engineering, ensuring quality and precision.

Real-world experience has shown that collaboration is key in casting for automotive applications. Engineers, metallurgists, and production line workers must work closely, combining their expertise to troubleshoot and refine casting methods. Quality control is rigorous, involving non-destructive testing techniques like X-ray inspections and ultrasound scans to detect any internal defects that could compromise part integrity. Innovation in casting technology is relentless. Recent advancements in 3D printing and AI have paved the way for more efficient prototyping and customization. By using 3D printed sand molds, manufacturers can significantly reduce lead times for new parts, allowing quicker iterations and adaptations. Meanwhile, AI-driven analysis helps in predicting potential casting defects, enhancing decision-making processes to attain superior output. Those who excel in casting automotive parts often exhibit a nuanced understanding of both historical practices and modern techniques, reinforcing their authoritative voice in the industry. As regulations around emissions and sustainability become stricter, the trustworthiness of a company's casting process becomes crucial. Ensuring that casting methods adhere to environmental standards, such as reducing energy consumption and waste in foundries, is not just environmentally responsible but also boosts consumer confidence. Through comprehensive understanding and application of these principles, companies can not only meet the present and future needs of the automotive industry but also contribute to its innovation and sustainability. The blend of experience, expertise, authority, and trustworthiness in casting automotive parts is where tradition meets the future, guiding the industry forward with quality and precision at every turn.

Real-world experience has shown that collaboration is key in casting for automotive applications. Engineers, metallurgists, and production line workers must work closely, combining their expertise to troubleshoot and refine casting methods. Quality control is rigorous, involving non-destructive testing techniques like X-ray inspections and ultrasound scans to detect any internal defects that could compromise part integrity. Innovation in casting technology is relentless. Recent advancements in 3D printing and AI have paved the way for more efficient prototyping and customization. By using 3D printed sand molds, manufacturers can significantly reduce lead times for new parts, allowing quicker iterations and adaptations. Meanwhile, AI-driven analysis helps in predicting potential casting defects, enhancing decision-making processes to attain superior output. Those who excel in casting automotive parts often exhibit a nuanced understanding of both historical practices and modern techniques, reinforcing their authoritative voice in the industry. As regulations around emissions and sustainability become stricter, the trustworthiness of a company's casting process becomes crucial. Ensuring that casting methods adhere to environmental standards, such as reducing energy consumption and waste in foundries, is not just environmentally responsible but also boosts consumer confidence. Through comprehensive understanding and application of these principles, companies can not only meet the present and future needs of the automotive industry but also contribute to its innovation and sustainability. The blend of experience, expertise, authority, and trustworthiness in casting automotive parts is where tradition meets the future, guiding the industry forward with quality and precision at every turn.

Prev:

Latest news

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025

PRODUCTS CATEGORIES