feb . 19, 2025 00:37

Back to list

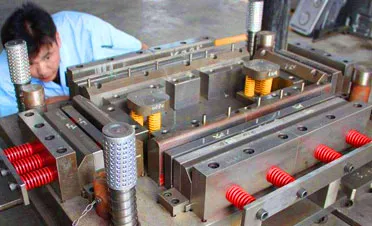

hot stamping plate

Hot stamping plates are integral components in the world of product branding and packaging, offering both aesthetic appeal and functional benefits. As a seasoned expert in hot stamping technologies, I have firsthand experience of how these tools can transform a product's visibility and perceived value in the market.

A critical aspect of hot stamping is the design preparation, which involves both graphical and technical skills. Design elements must be defined with precision to ensure that they translate well onto the final product. This phase involves engaging with software tools that can handle vector graphics, ensuring designs are scalable and compatible with the stamping machinery. This is where expertise truly shines—knowing which tools and settings when adjusted, accentuates the design's visual impact, whether it's the shimmer of metallic foils or the subtlety of a matte finish. Trustworthiness in the production of hot stamping plates is ensured through stringent quality controls and testing. It involves inspecting each plate for consistency, ensuring that the etch depth and line clearances are within specified tolerances. Moreover, regular calibration of stamping equipment minimizes the risks of misalignment or uneven pressure during the stamping process, thereby ensuring fidelity to the original design. The authority of a manufacturer or service provider in this industry often correlates with their ability to innovate and adapt. This field is in constant evolution, with advancements such as digital hot stamping and eco-friendly foils that eschew traditional PVC-based materials for more sustainable alternatives. Staying ahead requires investing in research and development, participating in trade shows, and engaging with cross-industry collaborations that foster innovation. In conclusion, hot stamping plates play a crucial role not just in beautifying a product, but in fortifying its market presence. Their success hinges upon a meticulous balance of material selection, design precision, and technological prowess. By adhering to these principles, businesses can ensure that their products not only catch the eye of consumers but also stand the test of time.

A critical aspect of hot stamping is the design preparation, which involves both graphical and technical skills. Design elements must be defined with precision to ensure that they translate well onto the final product. This phase involves engaging with software tools that can handle vector graphics, ensuring designs are scalable and compatible with the stamping machinery. This is where expertise truly shines—knowing which tools and settings when adjusted, accentuates the design's visual impact, whether it's the shimmer of metallic foils or the subtlety of a matte finish. Trustworthiness in the production of hot stamping plates is ensured through stringent quality controls and testing. It involves inspecting each plate for consistency, ensuring that the etch depth and line clearances are within specified tolerances. Moreover, regular calibration of stamping equipment minimizes the risks of misalignment or uneven pressure during the stamping process, thereby ensuring fidelity to the original design. The authority of a manufacturer or service provider in this industry often correlates with their ability to innovate and adapt. This field is in constant evolution, with advancements such as digital hot stamping and eco-friendly foils that eschew traditional PVC-based materials for more sustainable alternatives. Staying ahead requires investing in research and development, participating in trade shows, and engaging with cross-industry collaborations that foster innovation. In conclusion, hot stamping plates play a crucial role not just in beautifying a product, but in fortifying its market presence. Their success hinges upon a meticulous balance of material selection, design precision, and technological prowess. By adhering to these principles, businesses can ensure that their products not only catch the eye of consumers but also stand the test of time.

Prev:

Latest news

-

Precision Lost Wax Casting Factories | AI-Powered QualityNewsAug.04,2025

-

Smart OEM Coupling Solutions with GPT-4 TurboNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery|Precision Customization&Industrial SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Precision Engineering&Fluid ControlNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery | Custom Casting SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.02,2025

PRODUCTS CATEGORIES