die casting components manufacturers

The Role of Die Casting Components Manufacturers in Modern Industry

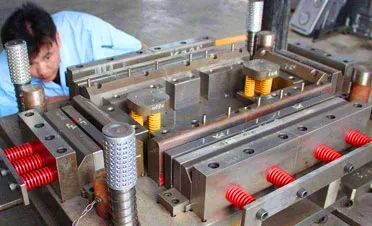

Die casting is a vital manufacturing process used to produce intricate and high-precision metal components. This technique involves forcing molten metal under high pressure into a mold cavity, resulting in pieces that are not only complex in shape but also exhibit exceptional surface finish and dimensional accuracy. The die casting industry has grown significantly, driven by advancements in technology and increasing demand across various sectors, including automotive, aerospace, consumer electronics, and industrial machinery. At the heart of this growth are die casting components manufacturers, whose roles are becoming increasingly crucial.

What Are Die Casting Components?

Die casting components are parts produced through the die casting process, typically made from non-ferrous metals such as aluminum, zinc, magnesium, and copper. These components are predominant in applications where high volumes and precise specifications are essential. Examples include engine blocks, transmission cases, enclosures for electronic devices, and structural components in aerospace applications. The durability and lightweight nature of die-cast components make them ideal for industries looking to optimize performance and reduce material costs.

The Importance of Die Casting Components Manufacturers

Die casting components manufacturers play a pivotal role in supply chains, providing the necessary expertise, technology, and innovation required to meet industry demands

. Here are some of the key contributions they make1. High Precision and Quality Control The accuracy of die casting components is critical. Manufacturers invest in advanced technologies such as computer-aided design (CAD) and computer-aided manufacturing (CAM) to enhance precision. Rigorous quality control measures are implemented to ensure that each component meets the required specifications, thus minimizing waste and rework.

die casting components manufacturers

2. Material Selection and Innovation The choice of material significantly impacts the performance of die casting components. Manufacturers not only choose appropriate metals based on the application but also innovate to develop new alloys and composites that enhance strength and reduce weight. This has led to improved performance in various applications, particularly in the automotive sector, where fuel efficiency and safety are paramount.

3. Customization and Prototyping In today’s fast-paced market, customization is crucial. Die casting components manufacturers often work closely with clients to develop tailored solutions that match specific requirements. Rapid prototyping capabilities allow for quick iterations and testing, accelerating the development process and reducing time-to-market for new products.

4. Sustainability Practices As industries strive for greener practices, die casting manufacturers are incorporating sustainable techniques. From energy-efficient melting processes to recycling scrap materials, manufacturers are finding ways to minimize their environmental impact. Some are also exploring the use of biodegradable or less harmful materials, aligning with global sustainability goals.

5. Technological Advancements The advent of Industry 4.0 has brought about significant changes in manufacturing, and die casting is no exception. Integration of IoT (Internet of Things) devices, AI (Artificial Intelligence), and robotics into the manufacturing process enhances efficiency, reduces downtime, and improves operational oversight. Manufacturers are leveraging these technologies to optimize production lines and maintain competitiveness in the market.

6. Global Competition and Market Expansion The die casting industry faces competition from regions with lower labor costs. However, manufacturers in developed markets are responding by focusing on high-quality products, exceptional customer service, and advanced manufacturing techniques. This focus not only helps them maintain market share but also drives innovation and standards within the industry.

Conclusion

In summary, die casting components manufacturers are essential players in the broader manufacturing landscape. They contribute significantly to the quality and efficiency of products across various industries while embracing technological advancements and sustainable practices. As demand continues to rise for high-quality, precision-engineered components, these manufacturers must remain agile and innovative, continually evolving to meet the changing needs of their clients and the industry at large. With their expertise and commitment to excellence, die casting manufacturers are poised to play a vital role in shaping the future of manufacturing.

-

Top Extras Casting Solutions Die Casting and Sand Casting Experts High-Quality Casting and Die Casting ServicesNewsJun.10,2025

-

Top SS Casting Manufacturer Aluminum Die Casting Manufacturer China Precision Die Casting Company SupplierNewsJun.10,2025

-

High-Quality Brass Casting Sand for Precision Sand Casting Brass at HomeNewsJun.10,2025

-

Affordable Aluminum Sand Casting Solutions Custom PartsNewsJun.09,2025

-

High-Quality China Sand Casting Services Cost-Effective & ReliableNewsJun.09,2025

-

Premium Hot Stamping Parts Durable Plastic Decor SolutionsNewsJun.09,2025