benefits of sand casting

The Benefits of Sand Casting

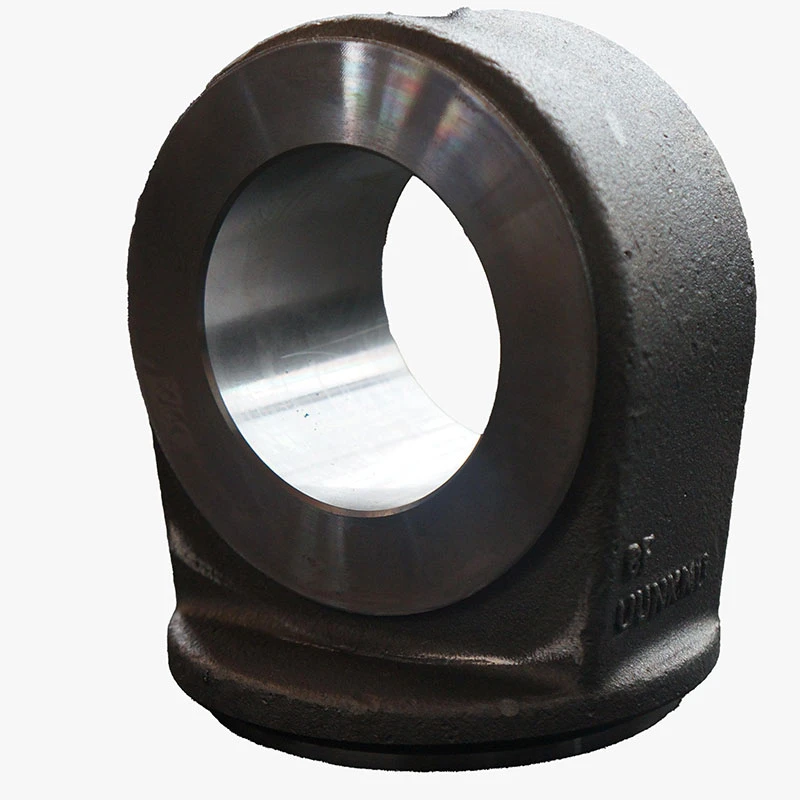

Sand casting, one of the oldest and most versatile forms of metal casting, has played an integral role in the manufacturing industry for centuries. This process involves creating a mold from sand and then pouring molten metal into that mold to produce a desired shape or part. While it has various applications across different fields, the benefits of sand casting make it particularly appealing for many manufacturing processes. In this article, we will explore the key advantages of sand casting and why it remains a popular choice for both small-scale and large-scale production.

1. Cost-Effectiveness

One of the most significant benefits of sand casting is its cost-effectiveness. The materials used in this process, particularly sand, are abundant and inexpensive. Moreover, sand molds can be reused multiple times, which further reduces costs. This makes sand casting an ideal choice for producing intricate designs and parts without breaking the bank. For businesses that require large quantities of metal parts, the reduced material and labor costs can lead to significant savings.

2. Versatility and Design Flexibility

Sand casting offers unparalleled versatility in terms of the shapes and sizes of components that can be produced. The process is suitable for both simple and complex geometries, allowing for the creation of a wide range of products from small to large. Additionally, sand has a high thermal conductivity, which means it can accommodate various metal types, including aluminum, bronze, and iron. This versatility enables manufacturers to experiment with different alloys and designs, promoting innovation.

3. Large-Scale Production Capabilities

Unlike other casting methods, sand casting can efficiently handle large production runs. With the ability to produce several molds in one go, manufacturers can scale their operations according to demand. Automated sand casting processes have further enhanced the speed and efficiency of production, allowing for faster turnaround times. This capability to produce high volumes without a significant increase in cost is vital in meeting market demands in industries such as automotive and aerospace.

benefits of sand casting

4. Minimal Tooling Requirements

Another significant advantage of sand casting is the minimal tooling required. Unlike other casting methods that may necessitate expensive and complex tooling systems, sand casting relies on simple molds typically made from sand and clay. This reduces initial investment costs and simplifies the setup process, making it accessible for smaller manufacturers and innovative startups. Additionally, modifications and adjustments can be easily made to the molds, facilitating rapid prototyping and iterative design processes.

5. Sustainability and Environmental Impact

In today's manufacturing landscape, sustainability is a crucial consideration. Sand casting is relatively environmentally friendly, as it primarily relies on recyclable materials. Sand can be reclaimed and reused multiple times in the process, minimizing waste. Moreover, many modern foundries are implementing more sustainable practices, such as using eco-friendly binders and reducing energy consumption in their operations. This emphasis on sustainability allows manufacturers to reduce their carbon footprint while meeting regulatory requirements and consumer expectations for environmentally conscious production.

6. Excellent Surface Finishing and Dimensional Accuracy

The surface finish obtained from sand casting can be quite good, depending on the quality of the sand and the casting process. With proper mold preparation and finishing techniques, the output can exhibit a high level of dimensional accuracy. This is particularly essential when producing components that need to fit together precisely in assemblies. While additional finishing processes may sometimes be required, the initial surface quality of sand-cast products can often meet the specifications of various applications.

Conclusion

Sand casting remains a cornerstone of the manufacturing industry due to its numerous benefits, including cost-effectiveness, versatility, capability for large-scale production, minimal tooling requirements, sustainability, and good surface finish. This method has adapted to modern manufacturing challenges, ensuring its relevance in today’s rapidly evolving market. As industries continue to seek innovative and efficient production methods, the advantages of sand casting position it as a leading choice for manufacturers across various sectors. Whether for prototyping or mass production, sand casting offers a reliable solution to meet a wide array of engineering and design needs.

-

Top Extras Casting Solutions Die Casting and Sand Casting Experts High-Quality Casting and Die Casting ServicesNewsJun.10,2025

-

Top SS Casting Manufacturer Aluminum Die Casting Manufacturer China Precision Die Casting Company SupplierNewsJun.10,2025

-

High-Quality Brass Casting Sand for Precision Sand Casting Brass at HomeNewsJun.10,2025

-

Affordable Aluminum Sand Casting Solutions Custom PartsNewsJun.09,2025

-

High-Quality China Sand Casting Services Cost-Effective & ReliableNewsJun.09,2025

-

Premium Hot Stamping Parts Durable Plastic Decor SolutionsNewsJun.09,2025