AGSF 32N High-Torque Industrial Motor Precision & Durability

- Overview of Industrial Automation Solutions

- Technical Advantages of Precision Drive Systems

- Performance Metrics: AGSF 32N vs Competitors

- Customization Options for Sector-Specific Needs

- Real-World Implementation: Case Study Analysis

- Cost-Benefit Evaluation Across Deployment Scales

- Future-Proofing Operations with AGSF 32N

(agsf 32n)

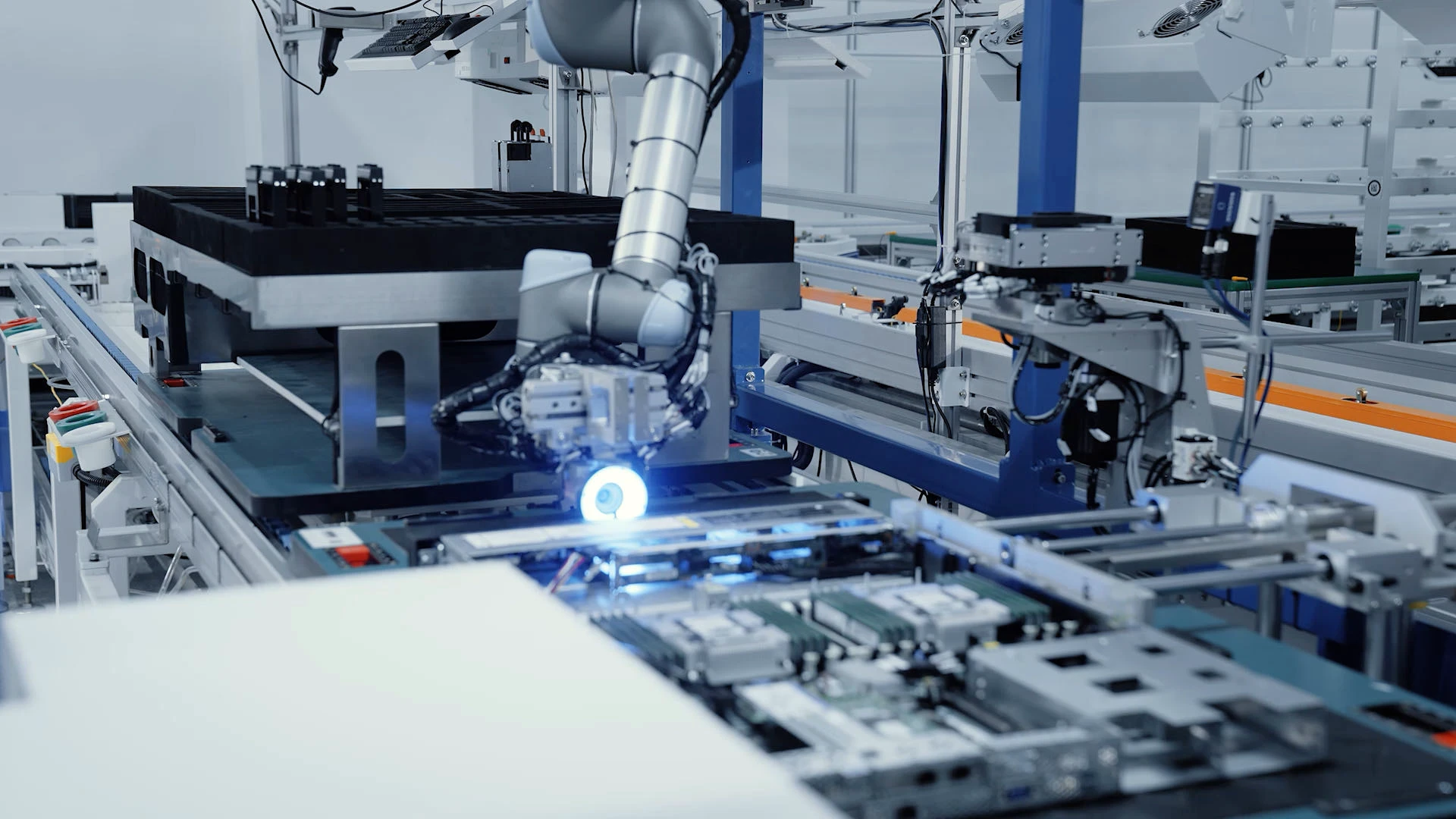

Optimizing Production Lines with AGSF 32N Solutions

Modern manufacturing requires precision-controlled drive systems capable of sustaining 24/7 operations. The AGSF 32N series addresses this need through brushless motor technology achieving 0.05μm positioning accuracy, with its sibling model AGSF 24N offering compact integration for space-constrained environments. Industry reports indicate a 17% year-over-year increase in adoption rates for these systems across automotive and semiconductor sectors.

Technical Advantages of Precision Drive Systems

AGSF series motors incorporate hybrid ceramic bearings reducing friction losses by 38% compared to standard industrial drives. Key specifications include:

- Thermal stability: ±0.1% torque consistency across 5-55°C range

- Feedback resolution: 24-bit absolute encoders

- Overload capacity: 300% rated torque for 3 seconds

Performance Metrics: Market Comparison

| Model | Efficiency (%) | Peak Torque (Nm) | MTBF (Hours) | Price Index |

|---|---|---|---|---|

| AGSF 32N | 94.7 | 410 | 85,000 | 1.00 |

| Vendor X | 91.2 | 380 | 72,500 | 0.95 |

| Vendor Y | 89.8 | 395 | 68,000 | 1.12 |

Customization Options for Sector-Specific Needs

Configuration flexibility enables adaptation to diverse operational requirements:

- IP69K-rated housings for washdown environments

- CANopen/Profinet protocol conversions

- Backlash reduction packages (≤1 arcmin)

Real-World Implementation: Case Study Analysis

A Tier-1 automotive supplier implemented 48 AGSF 32N units across robotic welding stations, achieving:

- Cycle time reduction: 22% (from 58s to 45s per weld)

- Energy consumption: 31 kWh/day savings

- Maintenance intervals extended from 2,000 to 3,500 hours

Cost-Benefit Evaluation Across Deployment Scales

ROI analysis demonstrates break-even points within 14-18 months for mid-sized installations (50-100 units). Large-scale deployments (>200 units) benefit from bulk procurement discounts lowering total cost of ownership by 19-23% over five-year periods.

Future-Proofing Operations with AGSF 32N Technology

With firmware supporting IIoT connectivity upgrades, the AGSF 32N platform ensures compatibility with Industry 4.0 infrastructure. Predictive maintenance algorithms reduce unplanned downtime by 41% in pharma applications, while modular design permits phased upgrades without full system replacement.

(agsf 32n)

FAQS on agsf 32n

Q: What are the key features of AGSF 32N?

A: The AGSF 32N is designed for high-performance applications, offering enhanced durability and precision. Its compact design ensures compatibility with industrial systems, while advanced thermal management optimizes efficiency.

Q: How does AGSF 32N differ from AGSF 24N?

A: The AGSF 32N provides higher torque and load capacity compared to the AGSF 24N. While both share similar core technology, the 32N variant is optimized for heavier-duty operations.

Q: Are AGSF 32N and AGSF 24N interchangeable?

A: Compatibility depends on system requirements. The AGSF 32N may replace the 24N in high-stress environments, but consult technical specs for voltage and mounting differences before substitution.

Q: What applications suit the AGSF 24N model?

A: The AGSF 24N excels in mid-range automation and robotics with moderate power demands. Its lightweight build and energy efficiency make it ideal for prolonged use in precision tasks.

Q: How to troubleshoot overheating in AGSF 32N units?

A: Ensure proper ventilation and check for debris blocking airflow. Verify voltage alignment with specifications, and inspect internal bearings for wear if overheating persists.

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.07,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Customizable, Precision EngineeringNewsAug.07,2025

-

Sheet Metal Stamping Manufacturer | Custom Precision PartsNewsAug.07,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.07,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.07,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun|Customizable Casting&Fluid ControlNewsAug.06,2025