feb . 13, 2025 20:25

Back to list

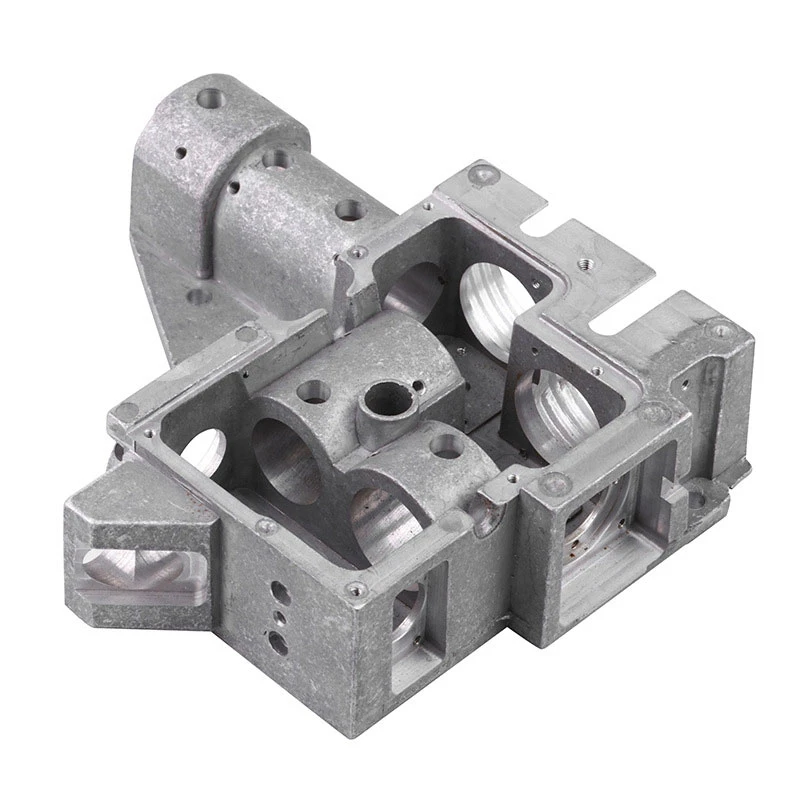

Oem Precision Castings Bearing

ADC10 aluminum is a standout material when it comes to selecting the ideal type of aluminum for diverse manufacturing needs. Heralded for its impressive casting characteristics, this alloy consistently leads the market in producing durable, reliable, and efficient components for various industrial applications. Tailored for professionals searching for high-quality material solutions, understanding the numerous advantages of ADC10 aluminum can set you apart as an informed leader in your field.

Sustainability is becoming an increasingly prominent focus in material selection, and ADC10 aluminum does not disappoint in this regard. Aluminum is inherently recyclable and this alloy is no exception. The recycling process does not degrade its inherent properties, allowing it to be reused repeatedly. This contributes significantly to reducing environmental impact and aligns with global sustainability goals—a compelling narrative for companies looking to enhance their corporate social responsibility profile. Industry experts often cite ADC10's adaptability across varied high-technology applications as one of its most attractive attributes. Whether employed in the production of engine components, intricate housings in consumer electronics, or structural elements in advanced architectural designs, ADC10 consistently delivers performance excellence. This reliability fosters trust and satisfaction among end-users and clients alike—indispensable attributes for maintaining competitive edge and fostering long-term business relationships. In terms of regulatory compliance, ADC10 aluminum meets an array of international manufacturing standards, making it an attractive choice for organizations operating on a global scale. Understanding and keeping abreast of regional regulations can prove time-consuming; however, the widespread acceptance of ADC10 simplifies this process, allowing manufacturers to focus on innovating and refining their core products without regulatory worries. To leverage expertise in the use of ADC10 aluminum, professionals in the field should pursue continuous education in metallurgy and manufacturing innovations. Engaging with industry publications, attending seminars, and participating in professional networks can provide invaluable insights and updates on the latest advances and trends. Additionally, partnerships with material scientists and suppliers can open up new avenues for utilizing ADC10's full potential, pushing the boundaries of what’s possible in material engineering. Ultimately, ADC10 aluminum exemplifies a modern engineering material that meets the multifaceted demands of today’s manufacturers. Its blend of casting ease, strength, corrosion resistance, recyclability, and broad regulatory compliance makes it a material of choice across sectors. Professionals who deepen their understanding of and proficiency in using ADC10 aluminum will undoubtedly enhance their capacity to deliver superior, sustainable, and innovative solutions in a competitive landscape.

Sustainability is becoming an increasingly prominent focus in material selection, and ADC10 aluminum does not disappoint in this regard. Aluminum is inherently recyclable and this alloy is no exception. The recycling process does not degrade its inherent properties, allowing it to be reused repeatedly. This contributes significantly to reducing environmental impact and aligns with global sustainability goals—a compelling narrative for companies looking to enhance their corporate social responsibility profile. Industry experts often cite ADC10's adaptability across varied high-technology applications as one of its most attractive attributes. Whether employed in the production of engine components, intricate housings in consumer electronics, or structural elements in advanced architectural designs, ADC10 consistently delivers performance excellence. This reliability fosters trust and satisfaction among end-users and clients alike—indispensable attributes for maintaining competitive edge and fostering long-term business relationships. In terms of regulatory compliance, ADC10 aluminum meets an array of international manufacturing standards, making it an attractive choice for organizations operating on a global scale. Understanding and keeping abreast of regional regulations can prove time-consuming; however, the widespread acceptance of ADC10 simplifies this process, allowing manufacturers to focus on innovating and refining their core products without regulatory worries. To leverage expertise in the use of ADC10 aluminum, professionals in the field should pursue continuous education in metallurgy and manufacturing innovations. Engaging with industry publications, attending seminars, and participating in professional networks can provide invaluable insights and updates on the latest advances and trends. Additionally, partnerships with material scientists and suppliers can open up new avenues for utilizing ADC10's full potential, pushing the boundaries of what’s possible in material engineering. Ultimately, ADC10 aluminum exemplifies a modern engineering material that meets the multifaceted demands of today’s manufacturers. Its blend of casting ease, strength, corrosion resistance, recyclability, and broad regulatory compliance makes it a material of choice across sectors. Professionals who deepen their understanding of and proficiency in using ADC10 aluminum will undoubtedly enhance their capacity to deliver superior, sustainable, and innovative solutions in a competitive landscape.

Latest news

-

Precision Machining & Manufacturing | Aerospace ExpertsNewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Precision, Quality, CustomizationNewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun|Precision Customization&Reliable Fluid ControlNewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Fluid Control, CustomizableNewsAug.05,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Precision Customization, Quality AssuranceNewsAug.05,2025

PRODUCTS CATEGORIES