Techniques for Welding Die Cast Metals in Manufacturing Processes and Applications

The Significance of Welding in Die-Cast Metal Fabrication

The die-casting process is a widely utilized manufacturing technique in various industries, most notably in automotive, electronics, and consumer goods. It involves forcing molten metal into a mold to produce intricate shapes with high dimensional accuracy and excellent surface finish. However, even with the advanced capabilities of die casting, there are scenarios where components need to be joined together, leading to the importance of welding in die-cast metal fabrication.

Understanding Die-Casting

Die casting typically uses non-ferrous metals, such as aluminum, zinc, and magnesium, known for their lightweight and corrosion-resistant properties. The process allows for mass production of parts that can be complex in design, requiring minimal secondary machining. However, despite its precision, there are instances where multiple components may need to be assembled. This need brings welding into the equation.

Welding Techniques for Die-Cast Metals

Welding die-cast metals presents unique challenges due to their specific properties. The melting points and thermal conductivities of these metals can complicate the welding process. Common techniques used in this context include

1. Gas Metal Arc Welding (GMAW) Also known as MIG welding, it is a versatile method suitable for die-cast aluminum and zinc alloys. This process uses a continuous wire feed as an electrode, creating an arc between the wire and the base metal.

2. TIG Welding (Tungsten Inert Gas Welding) This method provides greater control and precision, making it ideal for thin or intricate castings. A non-consumable tungsten electrode produces the weld, and the addition of filler material is often done manually.

3. Resistance Welding This technique generates heat through electrical resistance, making it possible to weld die-cast metals without extensive surface preparation. It is particularly useful for joining thin sections and for automated processes.

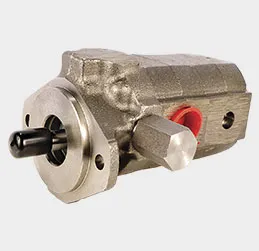

welding die cast metal

4. Electron Beam Welding Often used for high-precision work, this method involves a focused beam of electrons to melt the workpieces together in a vacuum, minimizing oxidation and ensuring strong welds.

Challenges in Welding Die-Cast Metals

While welding offers solutions for assembling die-cast components, it is not without its challenges. The high levels of porosity common in die-cast metals can lead to a reduction in weld quality. Porosity may occur due to trapped gases during the casting process, which can be exacerbated during welding. Moreover, die-cast alloys may have varying compositions, affecting their weldability.

Pre-heating the components before welding can help minimize the risk of cracking and improve the overall integrity of the welded joint. Additionally, selecting the right filler material that matches the base metal is crucial to achieving strong and reliable welds.

Importance of Proper Techniques

For manufacturers, adhering to correct welding techniques and practices is essential for maintaining production efficiency and product quality. Inadequate welding can lead to structural weaknesses, increased repair costs, and potential safety hazards. This underscores the importance of skilled labor and proper training in welding procedures specific to die-cast metals.

Conclusion

Welding die-cast metal components is an essential process for various industries that rely on the strength and durability of assembled parts. As manufacturers continue to innovate and push the boundaries of design and functionality, understanding the intricate relationship between die-casting and welding becomes increasingly important. By embracing advanced welding techniques and addressing the challenges that arise, industries can optimize their operations, delivering high-quality products that meet the demands of modern consumers. As technology evolves, the synergy between welding and die-cast metal fabrication will undoubtedly play a crucial role in the future of manufacturing.

-

Precision Casting AI Solution with GPT-4-Turbo | Optimized QualityNewsAug.02,2025

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025