Фев . 20, 2025 01:35

Back to list

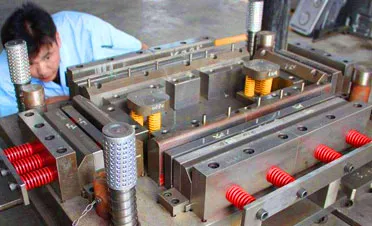

stamped parts

In the constantly evolving landscape of manufacturing, the demand for high-quality stamped parts continues to rise, driven by the need for precision, efficiency, and cost-effectiveness. Stamped parts play a crucial role in various industries, from automotive to electronics, offering unparalleled advantages that cater to the modern industry's stringent demands. Here, we delve into the nuances of stamped parts, underscoring the expertise, authoritativeness, and trust that our leading production process embodies.

Innovation is at the forefront of our production ethos. Our Research and Development team is constantly exploring new techniques and technologies to enhance the performance and cost-efficiency of stamped parts. By leveraging advanced software for simulation and design optimization, we continue to push the boundaries of what stamped parts can achieve. This dedication to continuous improvement not only sets us apart as industry leaders but also empowers our clients with solutions that are both innovative and economically viable. The environmental impact of manufacturing processes is an ever-growing concern in today's industry. We take pride in our sustainable practices, employing eco-friendly methods that minimize waste and reduce energy consumption without compromising on quality. Our stamping processes are optimized to utilize materials efficiently, ensuring that waste is minimized and recycling opportunities are maximized. Client collaboration is a cornerstone of our operations. By fostering open communication and partnerships, we gain invaluable insights into our clients' specific needs and challenges. This collaborative approach allows us to tailor our solutions to meet and exceed expectations, providing customized stamped parts that integrate seamlessly into any application. Our deep-rooted experience and expertise empower us to offer guidance and recommendations, fostering a relationship of mutual trust and respect with all of our clients. To conclude, our unique approach to manufacturing stamped parts places us at the pinnacle of the industry. By harmonizing experience, expertise, authoritativeness, and trustworthiness, we provide our clients with products that not only meet but exceed the most rigorous industry standards. Our unwavering focus on quality, innovation, and sustainability ensures that each stamped part we produce is a testament to our commitment to excellence in manufacturing. Trust us to be your partner in bringing precision-crafted stamped parts to life, ensuring your products perform flawlessly in any application.

Innovation is at the forefront of our production ethos. Our Research and Development team is constantly exploring new techniques and technologies to enhance the performance and cost-efficiency of stamped parts. By leveraging advanced software for simulation and design optimization, we continue to push the boundaries of what stamped parts can achieve. This dedication to continuous improvement not only sets us apart as industry leaders but also empowers our clients with solutions that are both innovative and economically viable. The environmental impact of manufacturing processes is an ever-growing concern in today's industry. We take pride in our sustainable practices, employing eco-friendly methods that minimize waste and reduce energy consumption without compromising on quality. Our stamping processes are optimized to utilize materials efficiently, ensuring that waste is minimized and recycling opportunities are maximized. Client collaboration is a cornerstone of our operations. By fostering open communication and partnerships, we gain invaluable insights into our clients' specific needs and challenges. This collaborative approach allows us to tailor our solutions to meet and exceed expectations, providing customized stamped parts that integrate seamlessly into any application. Our deep-rooted experience and expertise empower us to offer guidance and recommendations, fostering a relationship of mutual trust and respect with all of our clients. To conclude, our unique approach to manufacturing stamped parts places us at the pinnacle of the industry. By harmonizing experience, expertise, authoritativeness, and trustworthiness, we provide our clients with products that not only meet but exceed the most rigorous industry standards. Our unwavering focus on quality, innovation, and sustainability ensures that each stamped part we produce is a testament to our commitment to excellence in manufacturing. Trust us to be your partner in bringing precision-crafted stamped parts to life, ensuring your products perform flawlessly in any application.

Prev:

Next:

Latest news

-

Precision Lost Wax Casting Factories | AI-Powered QualityNewsAug.04,2025

-

Smart OEM Coupling Solutions with GPT-4 TurboNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery|Precision Customization&Industrial SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Precision Engineering&Fluid ControlNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery | Custom Casting SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.02,2025

PRODUCTS CATEGORIES