Янв . 13, 2025 16:01

Back to list

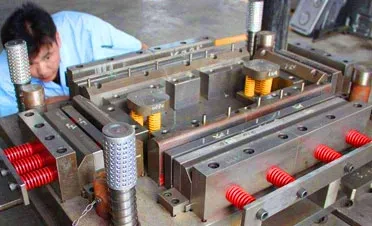

Oem Die-Cast Aluminium Parts

In the myriad of manufacturing processes, casting emerges as a crucial method that shapes various industries, from automotive to aerospace. One specific type, die casting, stands out due to its precision and efficiency. If you're navigating the waters of product manufacturing, understanding how die casting can enhance product quality is essential.

The economic benefits of die casting cannot be overstated. The ability to produce parts at a rapid rate minimizes labor costs and accelerates time-to-market, giving companies a competitive edge. Additionally, the efficiency of die casting translates to less waste of raw materials, benefiting both the business's bottom line and the environment. Expertise in Die Casting for Product Development Relying on experienced professionals in die casting ensures that products meet the stringent quality requirements of today’s markets. Skilled engineers utilize cutting-edge technologies and advanced software for designing dies that achieve optimal results. This expertise guarantees products with not only superior mechanical properties but also enhanced aesthetic appeal. For businesses keen on excellence, partnering with a trusted die-casting manufacturer boosts product credibility. A reputable provider offers comprehensive services, from design and prototyping to testing and production, instilling trust that the end product will consistently deliver on its promises. Ensuring Trustworthiness in Die Casting In a competitive landscape, ensuring trust is pivotal. Companies that adopt robust quality assurance processes stand out. Regular inspections, rigorous testing, and adherence to international standards build trust with clients. Practicing transparency by keeping clients informed throughout the production process further enhances reliability and customer satisfaction. Conclusion Incorporating die casting into product manufacturing not only achieves superior product quality but also maximizes efficiency and cost-effectiveness. By choosing this process, industries can leverage high precision, material versatility, and reduced production times, further supported by expertise and trustworthiness from seasoned specialists. This positions die casting as an indispensable method in the quest for excellence in product development.

The economic benefits of die casting cannot be overstated. The ability to produce parts at a rapid rate minimizes labor costs and accelerates time-to-market, giving companies a competitive edge. Additionally, the efficiency of die casting translates to less waste of raw materials, benefiting both the business's bottom line and the environment. Expertise in Die Casting for Product Development Relying on experienced professionals in die casting ensures that products meet the stringent quality requirements of today’s markets. Skilled engineers utilize cutting-edge technologies and advanced software for designing dies that achieve optimal results. This expertise guarantees products with not only superior mechanical properties but also enhanced aesthetic appeal. For businesses keen on excellence, partnering with a trusted die-casting manufacturer boosts product credibility. A reputable provider offers comprehensive services, from design and prototyping to testing and production, instilling trust that the end product will consistently deliver on its promises. Ensuring Trustworthiness in Die Casting In a competitive landscape, ensuring trust is pivotal. Companies that adopt robust quality assurance processes stand out. Regular inspections, rigorous testing, and adherence to international standards build trust with clients. Practicing transparency by keeping clients informed throughout the production process further enhances reliability and customer satisfaction. Conclusion Incorporating die casting into product manufacturing not only achieves superior product quality but also maximizes efficiency and cost-effectiveness. By choosing this process, industries can leverage high precision, material versatility, and reduced production times, further supported by expertise and trustworthiness from seasoned specialists. This positions die casting as an indispensable method in the quest for excellence in product development.

Next:

Latest news

-

Precision Casting AI Solution with GPT-4-Turbo | Optimized QualityNewsAug.02,2025

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

PRODUCTS CATEGORIES