Янв . 16, 2025 03:44

Back to list

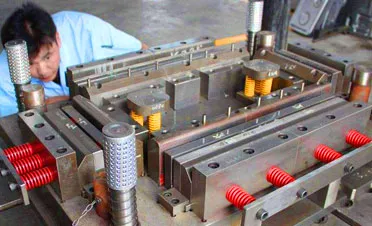

international precision casting supplies

When considering international precision casting supplies, the landscape is remarkably intricate yet brimming with innovative solutions essential across a multitude of industries from aerospace to medical devices. Having been a key player in this sector for years, my direct experience with these supplies has unveiled the intricate balance of quality, demand, and delivery that sets the stage for excellence in the field.

Credibility and trustworthiness are vital in such a specialized market. It involves steadfast adherence to international standards such as ISO 9001 and AS9100, which ensure quality management and aviation-specific quality assurance, respectively. Trust is further solidified through transparent communication with clients at every stage of production, from prototyping to final delivery, ensuring that expectations are aligned and met consistently. For businesses relying on precision casting supplies, the benefits of engaging with a trusted supplier are manifold. Not only do they offer reliability in the supply chain but also provide support in redesign and consulting services, ensuring that every product is optimized for its intended purpose. This results in a product lifecycle that is both efficient and sustainable, minimizing waste and enhancing end-user satisfaction. As a result of these dynamics, businesses need to thoroughly vet potential suppliers based on their track record, industry certifications, and feedback from previous clients. By prioritizing experience, expertise, authority, and trustworthiness, organizations can secure a partnership that not only meets their immediate needs but also propels them towards future innovation and competitiveness. In conclusion, international precision casting supplies remain a critical component in modern manufacturing. Their role in shaping the future of industries through high-quality, dependable solutions is indisputable. Engaging with experienced and reputable suppliers is not just a strategic advantage but a necessity for businesses aiming to optimize their operations and maintain the highest standards of excellence.

Credibility and trustworthiness are vital in such a specialized market. It involves steadfast adherence to international standards such as ISO 9001 and AS9100, which ensure quality management and aviation-specific quality assurance, respectively. Trust is further solidified through transparent communication with clients at every stage of production, from prototyping to final delivery, ensuring that expectations are aligned and met consistently. For businesses relying on precision casting supplies, the benefits of engaging with a trusted supplier are manifold. Not only do they offer reliability in the supply chain but also provide support in redesign and consulting services, ensuring that every product is optimized for its intended purpose. This results in a product lifecycle that is both efficient and sustainable, minimizing waste and enhancing end-user satisfaction. As a result of these dynamics, businesses need to thoroughly vet potential suppliers based on their track record, industry certifications, and feedback from previous clients. By prioritizing experience, expertise, authority, and trustworthiness, organizations can secure a partnership that not only meets their immediate needs but also propels them towards future innovation and competitiveness. In conclusion, international precision casting supplies remain a critical component in modern manufacturing. Their role in shaping the future of industries through high-quality, dependable solutions is indisputable. Engaging with experienced and reputable suppliers is not just a strategic advantage but a necessity for businesses aiming to optimize their operations and maintain the highest standards of excellence.

Latest news

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Engineering&Fluid ControlNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

PRODUCTS CATEGORIES