Exploring the Benefits and Techniques of Injection Die Casting in Manufacturing

Injection Die Casting An Overview of the Process and Benefits

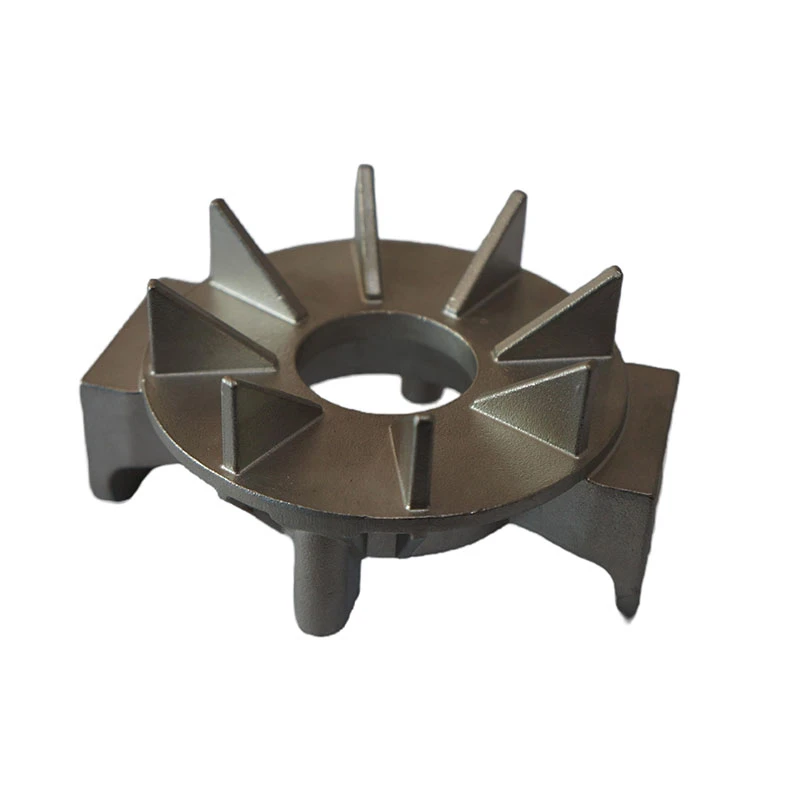

Injection die casting is a highly efficient manufacturing process widely used in various industries to produce complex metal parts with precision and speed. This technique involves forcing molten metal into a mold cavity under high pressure, allowing for the creation of intricate shapes and designs that would be difficult or impossible to achieve through other manufacturing methods. In this article, we will explore the fundamentals of injection die casting, its advantages, applications, and considerations when utilizing this process.

The Injection Die Casting Process

The injection die casting process begins with the selection of the appropriate metal alloy, commonly aluminum, zinc, or magnesium. These materials are favored for their excellent ductility, corrosion resistance, and lightweight properties. Once the metals are melted in a furnace, they are transferred to an injection machine. The machine consists of a hopper, an injection screw, a heated barrel, and a die.

The process can be summarized in several key steps

1. Melting The selected metal alloy is heated until it reaches a molten state. 2. Injection The molten metal is then injected into a preheated mold (or die) under high pressure. The pressure used can range from 500 to 4,000 psi (pounds per square inch) depending on the metal and complexity of the design.

3. Cooling Once the mold is filled, the molten metal cools and solidifies quickly, typically within seconds, forming the desired shape.

4. Ejection After sufficient cooling, the die opens, and ejector pins push the solidified part out of the mold.

5. Trimming and Finishing The component is then trimmed to remove excess material from the gates and flash, and any secondary finishing processes such as machining, polishing, or plating may follow.

Advantages of Injection Die Casting

Injection die casting offers numerous benefits that make it a preferred choice for many manufacturers

1. High Precision and Reproducibility The use of precision molds enables high accuracy in part dimensions. Once a mold is made, it can produce thousands of identical parts, ensuring consistency across production runs.

2. Complex Geometries The ability to create intricate designs allows manufacturers to produce complex components that feature fine details, undercuts, and thin walls.

injection die casting

3. Fast Production Rates This method supports rapid production cycles, making it ideal for high-volume manufacturing. The quick cooling and solidification process result in shorter lead times.

5. Surface Finish Parts produced via injection die casting typically have a good surface finish right out of the mold, reducing the need for extensive post-processing.

Applications of Injection Die Casting

The versatility of injection die casting allows its application across various industries. Some prominent areas include

- Automotive Components such as engine blocks, transmission housings, and structural parts leverage the strength-to-weight ratio provided by die-cast parts.

- Consumer Electronics Casings for smartphones, laptops, and other electronic devices require both aesthetic and durable components, which can be effectively produced using injection die casting.

- Aerospace The aerospace industry demands lightweight and high-strength parts, making injection die casting suitable for manufacturing brackets, housings, and other essential components.

- Medical Equipment Precision components in medical devices must adhere to strict regulations. Injection die casting meets these demands through its high accuracy and reliability.

Considerations in Injection Die Casting

While injection die casting offers numerous advantages, there are important factors to consider before initiating the process. The initial cost of creating a die can be significant, making it more economically viable for larger production runs. Additionally, manufacturing teams must factor in the design of the part, as certain geometries may require specialized tooling or modifications to the mold.

In summary, injection die casting is a highly efficient and versatile manufacturing technique with the capability to create intricate and durable parts across various industries. Its advantages in precision, speed, and material efficiency make it an attractive option for mass production. With advancements in technology and materials, the future of injection die casting promises continued innovation and expansion into new markets, further solidifying its role in modern manufacturing practices.

-

Top Extras Casting Solutions Die Casting and Sand Casting Experts High-Quality Casting and Die Casting ServicesNewsJun.10,2025

-

Top SS Casting Manufacturer Aluminum Die Casting Manufacturer China Precision Die Casting Company SupplierNewsJun.10,2025

-

High-Quality Brass Casting Sand for Precision Sand Casting Brass at HomeNewsJun.10,2025

-

Affordable Aluminum Sand Casting Solutions Custom PartsNewsJun.09,2025

-

High-Quality China Sand Casting Services Cost-Effective & ReliableNewsJun.09,2025

-

Premium Hot Stamping Parts Durable Plastic Decor SolutionsNewsJun.09,2025