Янв . 09, 2025 10:36

Back to list

Oem Precision Castings Impeller

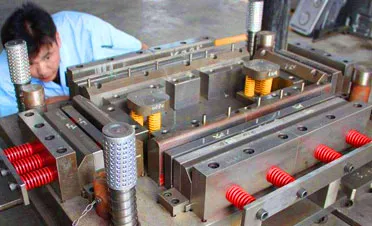

When selecting a die casting company, the stakes are high, especially when it pertains to product integrity, longevity, and overall success. Expert experience in die casting is not just about having a robust portfolio; it delves into the profound understanding of metallurgical principles, precision engineering, and state-of-the-art technology to deliver impeccable products.

Trustworthiness in a die casting company is built through transparency and a proven track record of successful projects. Reliable companies provide detailed project roadmaps, fostering open communication at every stage of the production process. They have robust quality control measures in place, including non-destructive testing and real-time monitoring systems, to ensure the finished product meets stringent specifications. Furthermore, an exceptional die casting company recognizes the critical importance of sustainability. They implement eco-friendly practices by optimizing resource use, recycling metal residues, and reducing energy consumption without compromising on product quality. This not only enhances corporate responsibility but aligns with the growing demand for greener manufacturing solutions. Client testimonials and case studies often highlight the pivotal role a die casting company plays in product development and optimization. Whether refining an existing design for cost efficiency or pioneering a new project from concept to production, the right partner proves invaluable. Their real-world experience becomes an asset, yielding insights that transform challenges into opportunities for client success. In conclusion, when evaluating a die casting company, consider their depth of experience, breadth of expertise, authoritative standing in the industry, and unwavering trustworthiness. The fusion of these attributes results in a partner capable of not only meeting your immediate product needs but helping innovate and secure your competitive edge in an ever-evolving market.

Trustworthiness in a die casting company is built through transparency and a proven track record of successful projects. Reliable companies provide detailed project roadmaps, fostering open communication at every stage of the production process. They have robust quality control measures in place, including non-destructive testing and real-time monitoring systems, to ensure the finished product meets stringent specifications. Furthermore, an exceptional die casting company recognizes the critical importance of sustainability. They implement eco-friendly practices by optimizing resource use, recycling metal residues, and reducing energy consumption without compromising on product quality. This not only enhances corporate responsibility but aligns with the growing demand for greener manufacturing solutions. Client testimonials and case studies often highlight the pivotal role a die casting company plays in product development and optimization. Whether refining an existing design for cost efficiency or pioneering a new project from concept to production, the right partner proves invaluable. Their real-world experience becomes an asset, yielding insights that transform challenges into opportunities for client success. In conclusion, when evaluating a die casting company, consider their depth of experience, breadth of expertise, authoritative standing in the industry, and unwavering trustworthiness. The fusion of these attributes results in a partner capable of not only meeting your immediate product needs but helping innovate and secure your competitive edge in an ever-evolving market.

Latest news

-

Precision Casting AI Solution with GPT-4-Turbo | Optimized QualityNewsAug.02,2025

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

PRODUCTS CATEGORIES