Fev . 16, 2025 15:00

Back to list

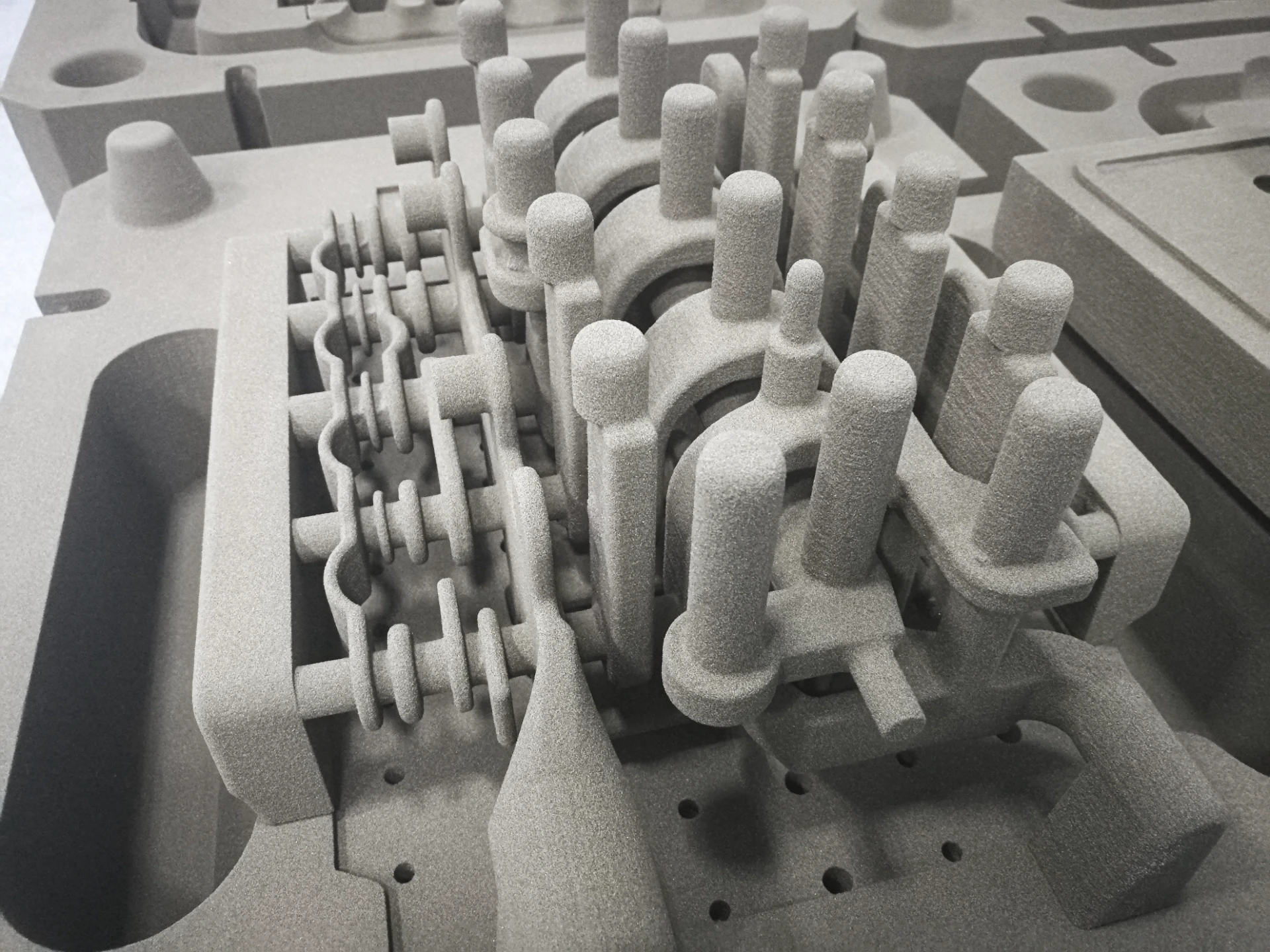

stamping parts factory

In the bustling world of manufacturing, a stamping parts factory often serves as a pivotal entity, producing components integral to myriad industries. These factories are renowned for their precision, reliability, and ability to produce high-quality metal parts that form the backbone of countless products globally.

The authoritative presence of a stamping parts factory within the manufacturing industry can be attributed to their certifications and adherence to international quality standards. Many of these factories are ISO-certified, ensuring that processes are streamlined and products are consistently of high quality. Furthermore, collaborations with global clients and the ability to meet rigorous industry regulations enhance their standing as authoritative providers of stamped metal parts. Their credibility is fortified through comprehensive testing protocols, including tensile strength assessments and dimensional inspections, which guarantee product integrity before delivery. Trustworthiness is an attribute that cannot be overstated when it comes to partnerships with a stamping parts factory. These factories pride themselves on building long-term relationships with clients by delivering on promises and maintaining transparency throughout the production lifecycle. Clear communication pathways, coupled with a commitment to sustainability and ethical practices, build confidence among all stakeholders. Moreover, an emphasis on timely delivery and responsive customer service ensures that clients can rely on their expertise during critical project phases. In conclusion, a stamping parts factory is not merely a production site; it is an interwoven tapestry of experience, expertise, authority, and trustworthiness. These attributes together create a robust foundation that supports industries worldwide, providing essential components with precision and reliability. By continuously adapting to technological advances and upholding the highest standards, these factories remain vital to the global manufacturing landscape, driving progress and innovation across diverse sectors.

The authoritative presence of a stamping parts factory within the manufacturing industry can be attributed to their certifications and adherence to international quality standards. Many of these factories are ISO-certified, ensuring that processes are streamlined and products are consistently of high quality. Furthermore, collaborations with global clients and the ability to meet rigorous industry regulations enhance their standing as authoritative providers of stamped metal parts. Their credibility is fortified through comprehensive testing protocols, including tensile strength assessments and dimensional inspections, which guarantee product integrity before delivery. Trustworthiness is an attribute that cannot be overstated when it comes to partnerships with a stamping parts factory. These factories pride themselves on building long-term relationships with clients by delivering on promises and maintaining transparency throughout the production lifecycle. Clear communication pathways, coupled with a commitment to sustainability and ethical practices, build confidence among all stakeholders. Moreover, an emphasis on timely delivery and responsive customer service ensures that clients can rely on their expertise during critical project phases. In conclusion, a stamping parts factory is not merely a production site; it is an interwoven tapestry of experience, expertise, authority, and trustworthiness. These attributes together create a robust foundation that supports industries worldwide, providing essential components with precision and reliability. By continuously adapting to technological advances and upholding the highest standards, these factories remain vital to the global manufacturing landscape, driving progress and innovation across diverse sectors.

Next:

Latest news

-

Precision Lost Wax Casting Factories | AI-Powered QualityNewsAug.04,2025

-

Smart OEM Coupling Solutions with GPT-4 TurboNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery|Precision Customization&Industrial SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Precision Engineering&Fluid ControlNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery | Custom Casting SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.02,2025

PRODUCTS CATEGORIES