Jan . 26, 2025 04:41

Back to list

sand casting manufacturers

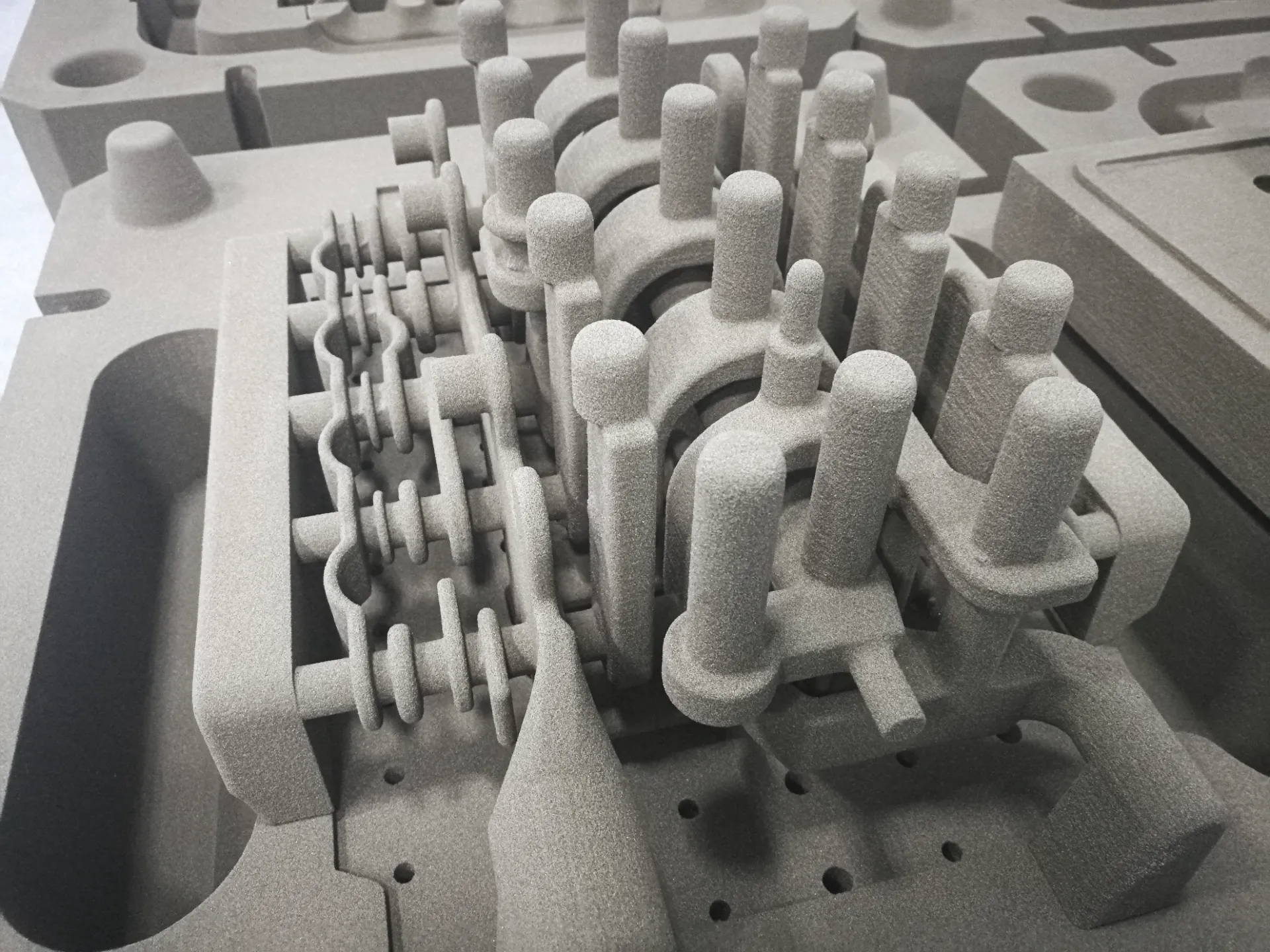

The landscape of the industrial sector constantly evolves, and its backbone, manufacturing processes, plays an integral role in its advancement. Among the myriad manufacturing methods, sand casting stands out as a time-tested and versatile technology for producing metal components. For industries seeking reliable sand casting manufacturers, understanding the nuances of the process, the expertise required, and the key players in the field is crucial.

Trustworthiness, an essential element when selecting a sand casting partner, is built over time through consistent delivery of quality, safely-manufactured components. Potential clients should seek testimonials and case studies that demonstrate a manufacturer’s capability to deliver on promises. Success stories illustrating reduced turnaround times, cost savings, or the resolution of complex casting challenges add layers of trust. Additionally, transparency in quoting, material sourcing, and communication throughout the manufacturing process contributes significantly to building and maintaining this trust. A successful manufacturing partnership hinges upon the harmonious blend of experience, expertise, authoritativeness, and trustworthiness. Sand casting manufacturers who exhibit these qualities not only facilitate production efficiency but also support the client’s overarching goals for innovation and competitive advantage. Emphasizing these aspects when choosing a manufacturer can lead to a fruitful synergy, aligning the capabilities of the manufacturer with the strategic objectives of the business seeking their services. The realm of sand casting continues to evolve, with technological advancements promising to enhance the precision, speed, and cost-effectiveness of the process. For industries on the brink of transformation, partnering with a forward-thinking sand casting manufacturer can be a catalyst for significant growth. By focusing on core qualities such as extensive experience, specialized expertise, recognized authority, and unwavering trustworthiness, companies can secure a manufacturing partner capable of propelling them towards their strategic objectives. In conclusion, the decision to engage with a sand casting manufacturer should be rooted in careful consideration of their history, technological investments, industry reputation, and customer feedback. Organizations that strategically select manufacturers aligned with these critical attributes are better positioned to achieve enhanced product quality, innovate consistently, and maintain a competitive advantage in their respective markets.

Trustworthiness, an essential element when selecting a sand casting partner, is built over time through consistent delivery of quality, safely-manufactured components. Potential clients should seek testimonials and case studies that demonstrate a manufacturer’s capability to deliver on promises. Success stories illustrating reduced turnaround times, cost savings, or the resolution of complex casting challenges add layers of trust. Additionally, transparency in quoting, material sourcing, and communication throughout the manufacturing process contributes significantly to building and maintaining this trust. A successful manufacturing partnership hinges upon the harmonious blend of experience, expertise, authoritativeness, and trustworthiness. Sand casting manufacturers who exhibit these qualities not only facilitate production efficiency but also support the client’s overarching goals for innovation and competitive advantage. Emphasizing these aspects when choosing a manufacturer can lead to a fruitful synergy, aligning the capabilities of the manufacturer with the strategic objectives of the business seeking their services. The realm of sand casting continues to evolve, with technological advancements promising to enhance the precision, speed, and cost-effectiveness of the process. For industries on the brink of transformation, partnering with a forward-thinking sand casting manufacturer can be a catalyst for significant growth. By focusing on core qualities such as extensive experience, specialized expertise, recognized authority, and unwavering trustworthiness, companies can secure a manufacturing partner capable of propelling them towards their strategic objectives. In conclusion, the decision to engage with a sand casting manufacturer should be rooted in careful consideration of their history, technological investments, industry reputation, and customer feedback. Organizations that strategically select manufacturers aligned with these critical attributes are better positioned to achieve enhanced product quality, innovate consistently, and maintain a competitive advantage in their respective markets.

Latest news

-

Technocrats Die Casting Solutions – Precision Hot & Cold Chamber Die Casting ExpertsNewsJun.24,2025

-

Precision Glass Machining Solutions Sand Casting Glass & Abrasive Water Jet Machining ExpertsNewsJun.24,2025

-

Top Extras Casting Solutions Die Casting and Sand Casting Experts High-Quality Casting and Die Casting ServicesNewsJun.10,2025

-

Top SS Casting Manufacturer Aluminum Die Casting Manufacturer China Precision Die Casting Company SupplierNewsJun.10,2025

-

High-Quality Brass Casting Sand for Precision Sand Casting Brass at HomeNewsJun.10,2025

-

Affordable Aluminum Sand Casting Solutions Custom PartsNewsJun.09,2025

PRODUCTS CATEGORIES