Mar . 05, 2025 01:58

Back to list

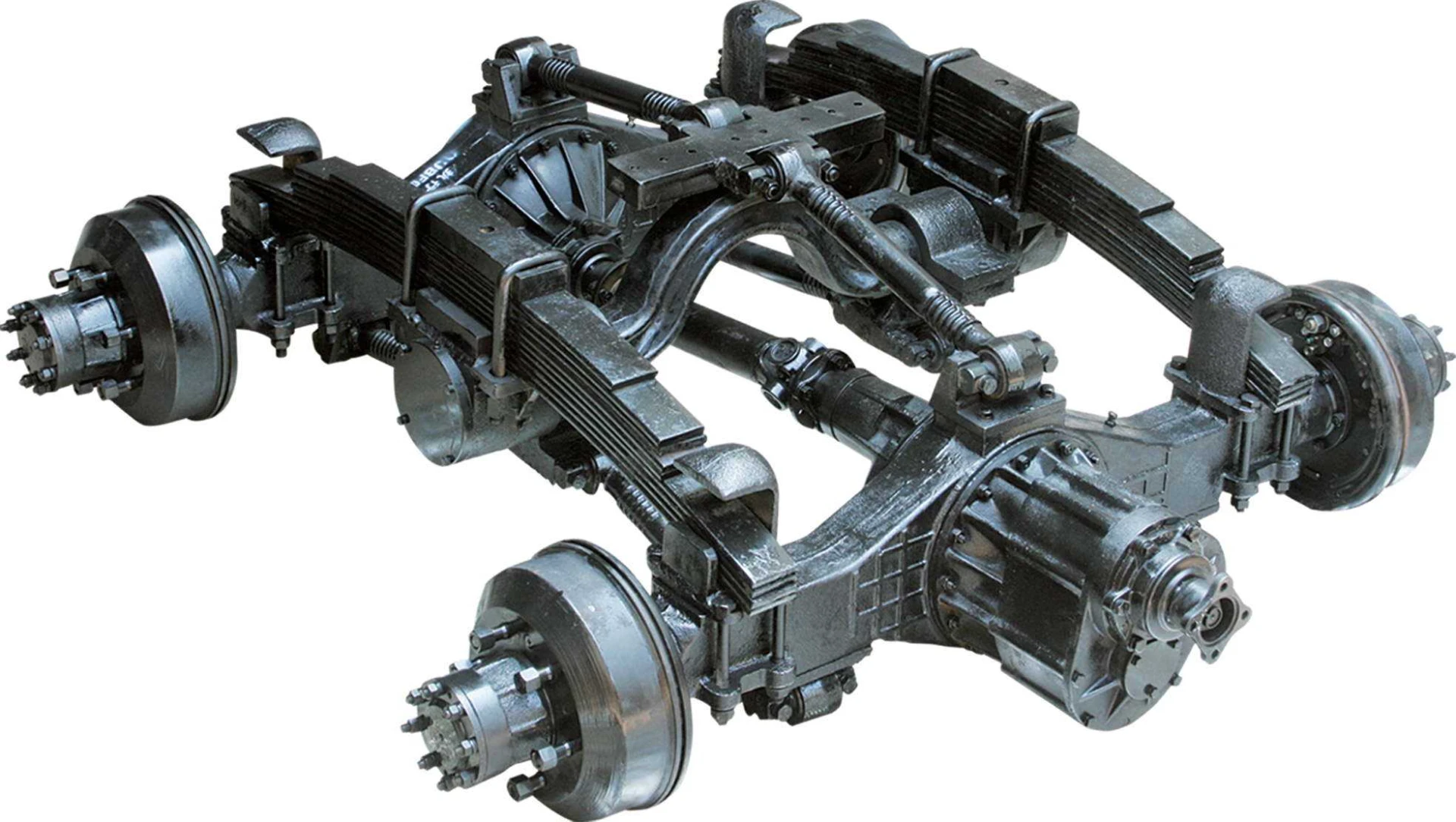

recreation industry metal stamping parts

The recreation industry stands as an exemplary sector where innovation and quality craftsmanship merge to create experiences that resonate with both consumers and manufacturers. At the heart of this innovation is the often-overlooked yet crucial process of metal stamping. This process not only fuels the recreation industry with components that assure durability and aesthetics but also propels it towards a future replete with promise. As industry experts, we delve into the multifaceted world of metal stamping parts, unraveling their significance in the recreation industry and highlighting why these components deserve a central focus for manufacturers and consumers alike.

Trustworthiness in the recreation industry stems from the assurance that equipment will perform as expected and withstand the tests of time and usage. Metal stamping contributes significantly to this trust by producing parts that boast intense durability and high resistance to wear and tear. Quality checks and rigorous testing validate that each stamped part meets the highest standards, providing manufacturers and consumers with confidence in product safety and effectiveness. The impact of metal stamping extends beyond just production. Sustainable practices in the recreation industry are increasingly relevant, and here, metal stamping offers environmentally friendly benefits. The process is known for its ability to reduce waste through precise cutting and efficient use of materials, contributing to a more sustainable production lifecycle. Furthermore, the recyclability of metals used in stamping supports ongoing industry efforts to minimize environmental footprints. Industry leaders agree that the future of the recreation sector relies heavily on innovation in component manufacturing. Metal stamping is poised to keep pace with evolving demands, thanks to its ability to scale with production needs and accommodate new technologies and materials as they emerge. This flexibility is vital as consumer preferences shift towards customized experiences, wherein stamped metal parts can be tailored to meet diverse specifications without compromising on quality or performance. In conclusion, metal stamping is an invaluable backbone of the recreation industry, trusted and recognized for its durability, precision, and adaptability. From designing new-age bicycles that promise speed and safety to crafting robust components for fitness equipment that withstand rigorous use, metal stamping defines the quality and longevity that consumers demand. As stewards of this evolving landscape, we emphasize the importance of informed material selection, cutting-edge design practices, and sustainable manufacturing processes that will sustain the recreation industry’s vibrant and dynamic future.

Trustworthiness in the recreation industry stems from the assurance that equipment will perform as expected and withstand the tests of time and usage. Metal stamping contributes significantly to this trust by producing parts that boast intense durability and high resistance to wear and tear. Quality checks and rigorous testing validate that each stamped part meets the highest standards, providing manufacturers and consumers with confidence in product safety and effectiveness. The impact of metal stamping extends beyond just production. Sustainable practices in the recreation industry are increasingly relevant, and here, metal stamping offers environmentally friendly benefits. The process is known for its ability to reduce waste through precise cutting and efficient use of materials, contributing to a more sustainable production lifecycle. Furthermore, the recyclability of metals used in stamping supports ongoing industry efforts to minimize environmental footprints. Industry leaders agree that the future of the recreation sector relies heavily on innovation in component manufacturing. Metal stamping is poised to keep pace with evolving demands, thanks to its ability to scale with production needs and accommodate new technologies and materials as they emerge. This flexibility is vital as consumer preferences shift towards customized experiences, wherein stamped metal parts can be tailored to meet diverse specifications without compromising on quality or performance. In conclusion, metal stamping is an invaluable backbone of the recreation industry, trusted and recognized for its durability, precision, and adaptability. From designing new-age bicycles that promise speed and safety to crafting robust components for fitness equipment that withstand rigorous use, metal stamping defines the quality and longevity that consumers demand. As stewards of this evolving landscape, we emphasize the importance of informed material selection, cutting-edge design practices, and sustainable manufacturing processes that will sustain the recreation industry’s vibrant and dynamic future.

Next:

Latest news

-

Precision Lost Wax Casting Factories | AI-Powered QualityNewsAug.04,2025

-

Smart OEM Coupling Solutions with GPT-4 TurboNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery|Precision Customization&Industrial SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Precision Engineering&Fluid ControlNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery | Custom Casting SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.02,2025

PRODUCTS CATEGORIES