Best Options for Casting Sand

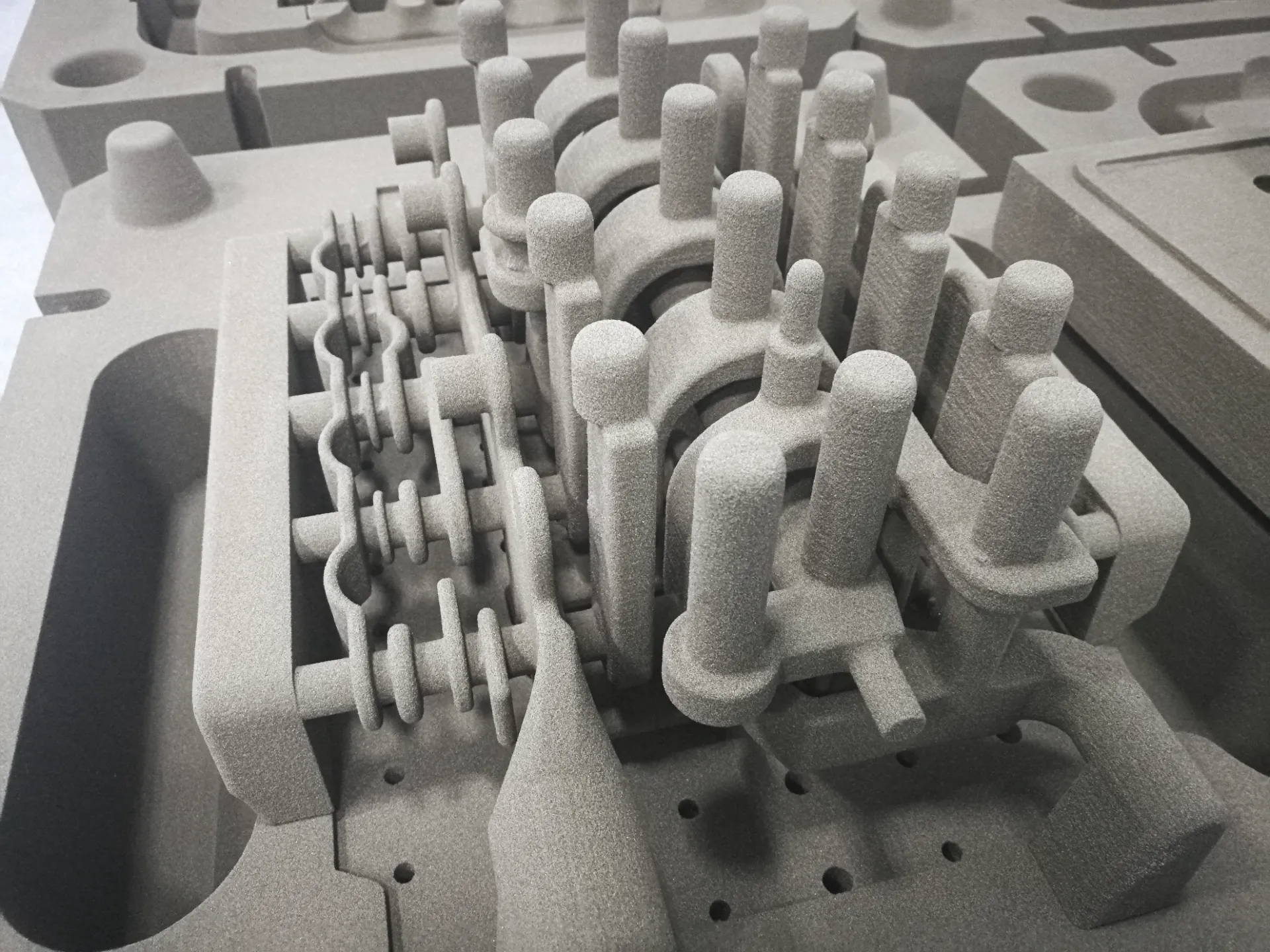

When it comes to precision metal casting, finding the right casting sand for sale is essential for achieving high-quality results. Casting sand is a vital component in the sand casting process, which involves creating molds to shape molten metal into desired forms. Whether you’re in the automotive, aerospace, or industrial manufacturing sector, choosing the right casting sand can make all the difference in the durability, strength, and surface finish of the final product.

High-quality casting sand for sale comes in various grades to suit different applications. It provides excellent moldability and thermal resistance, ensuring that the mold maintains its integrity during the casting process. Additionally, using premium casting sand can reduce defects, such as porosity or shrinkage, resulting in parts that meet or exceed your specifications.

From small-scale artisans to large manufacturers, sourcing reliable casting sand for sale ensures consistent results in every production cycle. Reputable suppliers offer sands that are tested for quality and designed to perform under varying conditions, making them an essential resource for businesses seeking efficiency and excellence in metal casting.

Benefits of Choosing Green Sand Casting for Sale

Among the many types of casting sands available, green sand casting for sale is one of the most popular options for producing high-quality castings. Green sand, a mixture of silica sand, clay, water, and other additives, is known for its versatility and affordability. The term "green" refers to the moisture content in the sand, which gives it its moldable consistency.

The primary advantage of green sand casting for sale is its cost-effectiveness. This method is ideal for producing small to medium-sized parts in large quantities without compromising on quality. Industries such as automotive and machinery manufacturing rely on green sand casting for its ability to create intricate details and tight tolerances.

Another key benefit of green sand casting for sale is its eco-friendly nature. The materials used in green sand molds can often be recycled and reused, reducing waste and promoting sustainable manufacturing practices. This makes it a top choice for companies looking to balance performance with environmental responsibility.

Understanding Different Casting Sand Types

Selecting the right casting sand types is a critical decision in the casting process, as the sand directly impacts the quality of the final product. Each type of casting sand has unique properties, making it suitable for specific applications and casting methods. By understanding the various casting sand types, manufacturers can ensure optimal results for their projects.

The most common casting sand types include silica sand, zircon sand, and chromite sand. Silica sand is widely used due to its affordability and excellent moldability, while zircon sand is preferred for its high thermal conductivity and low thermal expansion, making it ideal for precision applications. Chromite sand, on the other hand, is known for its high refractoriness and strength, making it suitable for heavy-duty castings.

Choosing between casting sand types depends on factors like the type of metal being cast, the complexity of the part, and the required surface finish. Reputable suppliers offer a range of casting sand types, helping businesses select the best option for their specific needs and ensuring that each component meets the required performance standards.

Partner with a Reliable Sand Casting Manufacturer

A successful sand casting process requires the expertise of a dependable sand casting manufacturer. These manufacturers specialize in creating molds and casting metal parts that meet the most demanding specifications. By partnering with a professional sand casting manufacturer, businesses can streamline their production processes and ensure consistent, high-quality results.

A leading sand casting manufacturer offers a comprehensive range of services, from design assistance and material selection to mold preparation and finishing. This end-to-end approach helps clients optimize their production while minimizing waste and costs. Furthermore, experienced manufacturers use advanced equipment and techniques to produce components with excellent dimensional accuracy and surface finishes.

Choosing the right sand casting manufacturer also ensures access to a variety of sand options, including casting sand types tailored to your project. Whether you need a small batch of prototypes or a large-scale production run, a professional sand casting manufacturer can deliver solutions that meet your unique requirements.

Future Trends in Casting Sand for Sale and Metal Casting

The market for casting sand for sale is continually evolving as industries demand higher precision and efficiency in the casting process. Advancements in sand casting technology, combined with innovative materials, are driving improvements in the quality and sustainability of cast metal components. For businesses looking to stay ahead in their respective industries, staying informed about these trends is crucial.

One emerging trend is the development of reusable and environmentally friendly casting sand types, which reduce waste and lower costs without compromising performance. Additionally, automation and digital technologies are transforming the casting process, allowing manufacturers to produce components with greater accuracy and speed.

For businesses seeking green sand casting for sale or other premium options, the future holds exciting possibilities for enhancing production capabilities. By working closely with a trusted sand casting manufacturer, companies can access cutting-edge solutions and maintain a competitive edge in the global market. From innovative materials to advanced manufacturing processes, the world of casting sand continues to offer new opportunities for excellence in metal casting.

-

Why Choose OEM Spark Plugs for Optimal Engine PerformanceNewsJul.16,2025

-

Unlock the Power of Die CastingNewsJul.16,2025

-

The Power of Sand Casting for Your Manufacturing NeedsNewsJul.16,2025

-

The Excellence of Precision CastingsNewsJul.16,2025

-

Maximize Efficiency with High-Quality Stamping PartsNewsJul.16,2025

-

Enhance Your Manufacturing with Aluminium Die CastingsNewsJul.16,2025