2月 . 15, 2025 09:38

Back to list

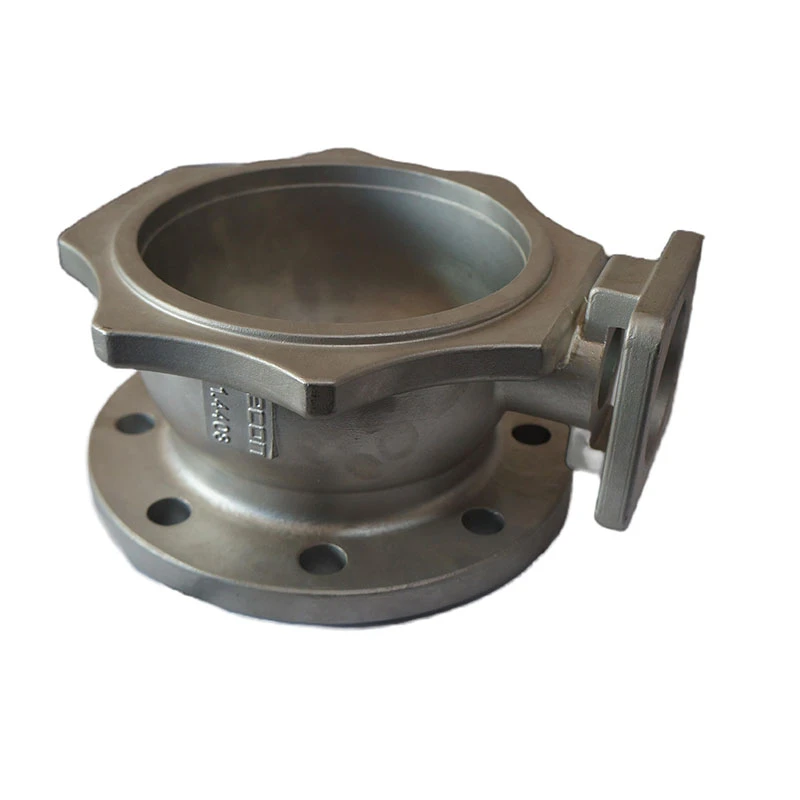

zinc pressure die casting

Zinc pressure die casting stands as a cornerstone in modern manufacturing, seamlessly integrating cutting-edge technology with time-tested processes to produce intricate metal components with precision. Its significance in the industrial world cannot be overstated, particularly in sectors like automotive, telecommunications, and consumer electronics, where quality and efficiency are paramount.

Trustworthiness is an attribute naturally associated with zinc pressure die casting due to its consistent delivery of high-quality components. Companies that invest in this technology often find that their reputation for reliability increases with every batch of components shipped. The controlled process of die casting ensures that each part produced is identical, maintaining strict adherence to technical specifications. This consistency enables manufacturers to promise and deliver not only high quality but also uniformity across production batches, reassuring clients from quality-driven industries. In addition to these advantages, sustainability is an emerging area where zinc pressure die casting shines. Zinc is 100% recyclable without any loss of physical properties, making it an environmentally friendly option for conscientious manufacturers. Today's consumers and businesses are more environmentally aware than ever before, and utilizing sustainable practices like zinc recycling can position a company as both innovative and responsible. The ability to reuse zinc scrap reduces raw material costs and minimizes environmental impact — thus offering an economical and ecologically sound manufacturing solution. In conclusion, zinc pressure die casting is not just a manufacturing process; it is a strategic advantage in the competitive landscape of modern industry. By leveraging the inherent properties of zinc with state-of-the-art casting techniques, manufacturers can achieve unparalleled precision, cost efficiency, and sustainability. Whether it's for intricate electronic enclosures or durable automotive parts, the promise and delivery of zinc pressure die casting remain unmatched. As the industrial world continues to evolve, the reliability and innovation of zinc die casting will undoubtedly play a pivotal role in the future of manufacturing.

Trustworthiness is an attribute naturally associated with zinc pressure die casting due to its consistent delivery of high-quality components. Companies that invest in this technology often find that their reputation for reliability increases with every batch of components shipped. The controlled process of die casting ensures that each part produced is identical, maintaining strict adherence to technical specifications. This consistency enables manufacturers to promise and deliver not only high quality but also uniformity across production batches, reassuring clients from quality-driven industries. In addition to these advantages, sustainability is an emerging area where zinc pressure die casting shines. Zinc is 100% recyclable without any loss of physical properties, making it an environmentally friendly option for conscientious manufacturers. Today's consumers and businesses are more environmentally aware than ever before, and utilizing sustainable practices like zinc recycling can position a company as both innovative and responsible. The ability to reuse zinc scrap reduces raw material costs and minimizes environmental impact — thus offering an economical and ecologically sound manufacturing solution. In conclusion, zinc pressure die casting is not just a manufacturing process; it is a strategic advantage in the competitive landscape of modern industry. By leveraging the inherent properties of zinc with state-of-the-art casting techniques, manufacturers can achieve unparalleled precision, cost efficiency, and sustainability. Whether it's for intricate electronic enclosures or durable automotive parts, the promise and delivery of zinc pressure die casting remain unmatched. As the industrial world continues to evolve, the reliability and innovation of zinc die casting will undoubtedly play a pivotal role in the future of manufacturing.

Prev:

Latest news

-

Precision Machining & Manufacturing | Aerospace ExpertsNewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Precision, Quality, CustomizationNewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun|Precision Customization&Reliable Fluid ControlNewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Fluid Control, CustomizableNewsAug.05,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Precision Customization, Quality AssuranceNewsAug.05,2025

PRODUCTS CATEGORIES