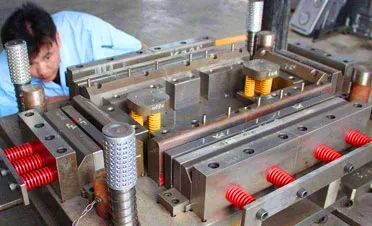

small part metal stamping

The Importance of Small Part Metal Stamping in Manufacturing

In the realm of manufacturing, small part metal stamping plays a crucial role across various industries. This process involves the use of dies to shape and cut metal sheets into components of intricate designs and precise dimensions. While the focus often leans towards larger assemblies or parts, the significance of small metal stamped parts cannot be understated.

Understanding Metal Stamping

Metal stamping is a comprehensive umbrella term that encompasses several processes, including blanking, bending, and forming. This technology allows for the efficient production of high-quality metal parts in large quantities. The methodology typically employs high-speed presses and advanced dies that ensure accuracy, repeatability, and cost-effectiveness. As industries evolve and demand changes, the role of small part metal stamping becomes increasingly vital.

Applications in Various Industries

Small stamped metal parts are ubiquitous in numerous sectors. In the automotive industry, for instance, they are used for creating everything from brackets to clips, electrical connectors, and more. These components might appear minor at first glance, yet they are essential for the overall functionality of vehicles. They contribute not only to structural integrity but also to safety and performance.

The electronics sector is another significant area where small metal stamping is prevalent. Components such as battery contacts, connectors, and enclosures are routinely manufactured through stamping processes. As technology advances and devices become more compact and integrated, the need for precise and small metal parts continues to escalate. Manufacturers in this field rely on stamping to produce parts that meet stringent tolerances while maintaining efficiency and affordability.

Benefits of Small Part Metal Stamping

One of the primary advantages of small part metal stamping is its efficiency in mass production. Once the initial setup with dies is completed, manufacturers can produce thousands of identical parts rapidly. This efficiency not only reduces production costs but also minimizes waste, making it a more sustainable option compared to other manufacturing methods.

small part metal stamping

Moreover, metal stamping allows for greater complexity in part design. With the ability to create intricate shapes and features, stamped parts can often replace multiple machined components, leading to streamlined assembly processes. This level of design freedom enables engineers to innovate and enhance product functionality, which is particularly advantageous in competitive markets where differentiation is key.

Quality Control and Precision

In industries where safety and precision are paramount, such as aerospace and medical devices, the quality of small stamped metal parts is critical. Modern stamping technologies incorporate advanced quality control measures, ensuring that each component produced adheres to strict specifications. Techniques like automated inspection and measurement systems are employed to detect defects early in the manufacturing process, reducing the likelihood of errors reaching the final product.

Challenges and Considerations

Despite its many advantages, small part metal stamping does come with challenges. The initial cost of die creation can be substantial, and for small production runs, this can make the process economically unfeasible. However, with advancements in technology such as rapid prototyping and CNC machining, manufacturers can now create efficient production methods that balance up-front costs against long-term production benefits.

Additionally, the choice of material for stamped components is critical. Different metals possess varying properties that affect durability, weight, and corrosion resistance. Manufacturers must carefully select the right material based on the end-use of the component, further complicating the design and production process.

Conclusion

In summary, small part metal stamping is a vital technique within the manufacturing landscape, offering unparalleled efficiency, precision, and versatility. Its applications are diverse, spanning industries from automotive to electronics. While there are challenges to navigate, the benefits usually far outweigh the drawbacks, making it an indispensable tool for producing high-quality components that meet the ever-changing demands of modern technology. As innovation continues to drive the industry forward, the future of small part metal stamping looks promising, with enhanced techniques and materials paving the way for even greater advancements.

-

Precision Casting AI Solution with GPT-4-Turbo | Optimized QualityNewsAug.02,2025

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025