2月 . 18, 2025 04:33

Back to list

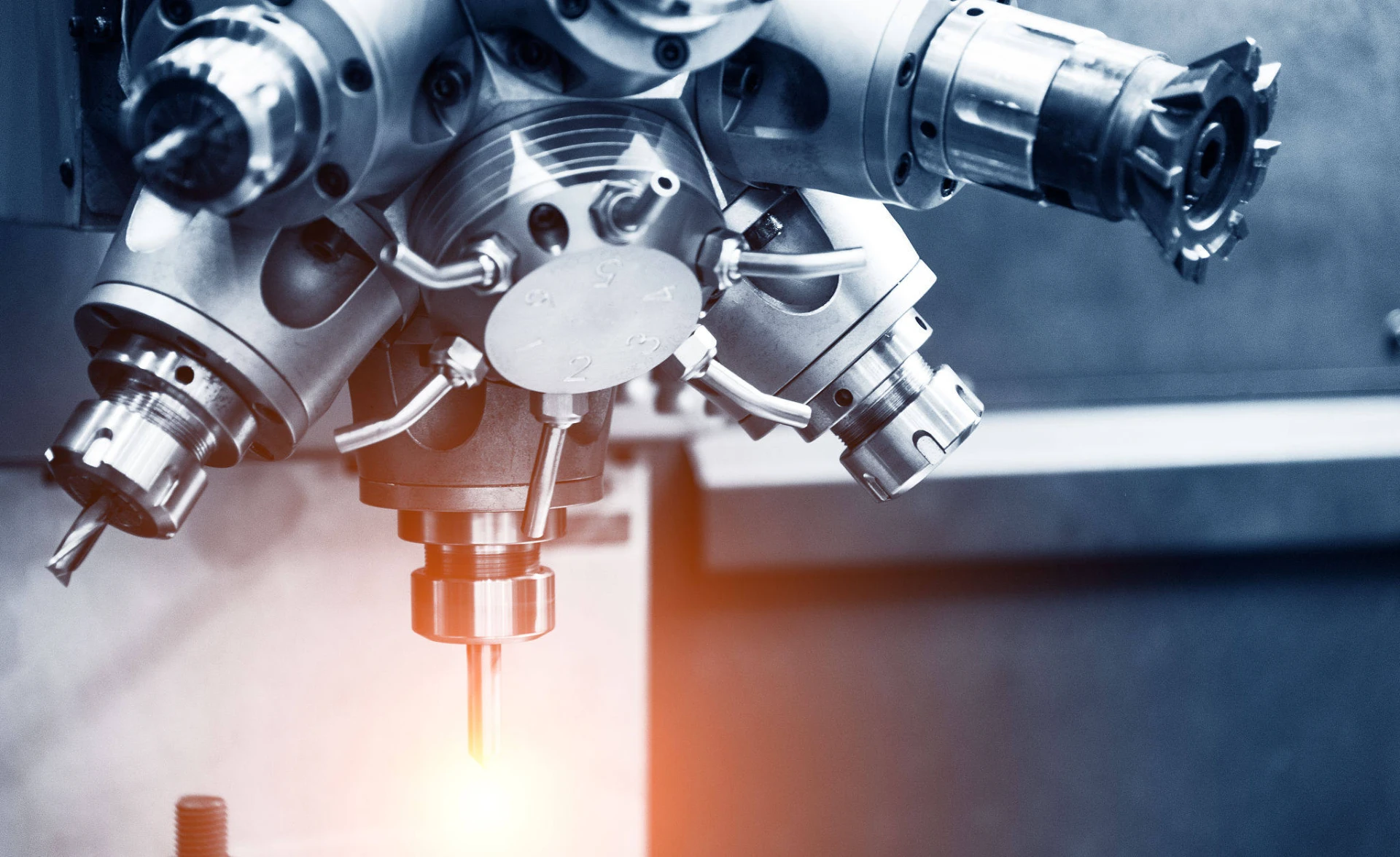

precision sheet metal stamping

Precision sheet metal stamping stands at the forefront of modern manufacturing, providing quintessential components essential for a myriad of industries. The process involves transforming flat sheet metal into geometrically complex parts and structures through a reiterated action using stamping press machines. As someone deeply entrenched in this field, with extensive experience and unparalleled expertise, it’s evident how integral this process is to advancing technological innovation.

Technical skill set is complemented by an ethos of sustainability. In an age where environmental consciousness is paramount, adopting eco-friendly practices such as recycling scrap metal and minimizing energy consumption aligns production processes with global sustainability goals. This commitment not only enhances corporate responsibility but also fortifies trust with environmentally aware clients and stakeholders. Anticipating future trends, integration of smart technologies like the Internet of Things (IoT) within our processes streamlines production efficiency and provides valuable data insights. Additionally, the advent of Industry 4.0 heralds the potential for unprecedented advancements in precision sheet metal stamping. From predictive maintenance to real-time monitoring systems, these innovations are set to revolutionize component manufacturing. Understanding the cultural landscape in which precision sheet metal stamping operates is crucial. Maintaining a competitive edge requires not just technical expertise but an appreciation of market dynamics. Continuous engagement with industry forums and participation in global expositions fosters knowledge exchange, positioning us at the cutting edge of technological advancements and market awareness. Precision sheet metal stamping is more than a manufacturing process—it's a craft grounded in technical prowess and sustained through unwavering commitment to excellence. As the industry evolves, so too does the capability to meet ever-more-complex requirements. With exacting standards and visionary innovation, the future holds limitless possibilities for those at the helm of this transformative industry.

Technical skill set is complemented by an ethos of sustainability. In an age where environmental consciousness is paramount, adopting eco-friendly practices such as recycling scrap metal and minimizing energy consumption aligns production processes with global sustainability goals. This commitment not only enhances corporate responsibility but also fortifies trust with environmentally aware clients and stakeholders. Anticipating future trends, integration of smart technologies like the Internet of Things (IoT) within our processes streamlines production efficiency and provides valuable data insights. Additionally, the advent of Industry 4.0 heralds the potential for unprecedented advancements in precision sheet metal stamping. From predictive maintenance to real-time monitoring systems, these innovations are set to revolutionize component manufacturing. Understanding the cultural landscape in which precision sheet metal stamping operates is crucial. Maintaining a competitive edge requires not just technical expertise but an appreciation of market dynamics. Continuous engagement with industry forums and participation in global expositions fosters knowledge exchange, positioning us at the cutting edge of technological advancements and market awareness. Precision sheet metal stamping is more than a manufacturing process—it's a craft grounded in technical prowess and sustained through unwavering commitment to excellence. As the industry evolves, so too does the capability to meet ever-more-complex requirements. With exacting standards and visionary innovation, the future holds limitless possibilities for those at the helm of this transformative industry.

Prev:

Latest news

-

Precision Lost Wax Casting Factories | AI-Powered QualityNewsAug.04,2025

-

Smart OEM Coupling Solutions with GPT-4 TurboNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery|Precision Customization&Industrial SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Precision Engineering&Fluid ControlNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery | Custom Casting SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.02,2025

PRODUCTS CATEGORIES