2月 . 18, 2025 11:25

Back to list

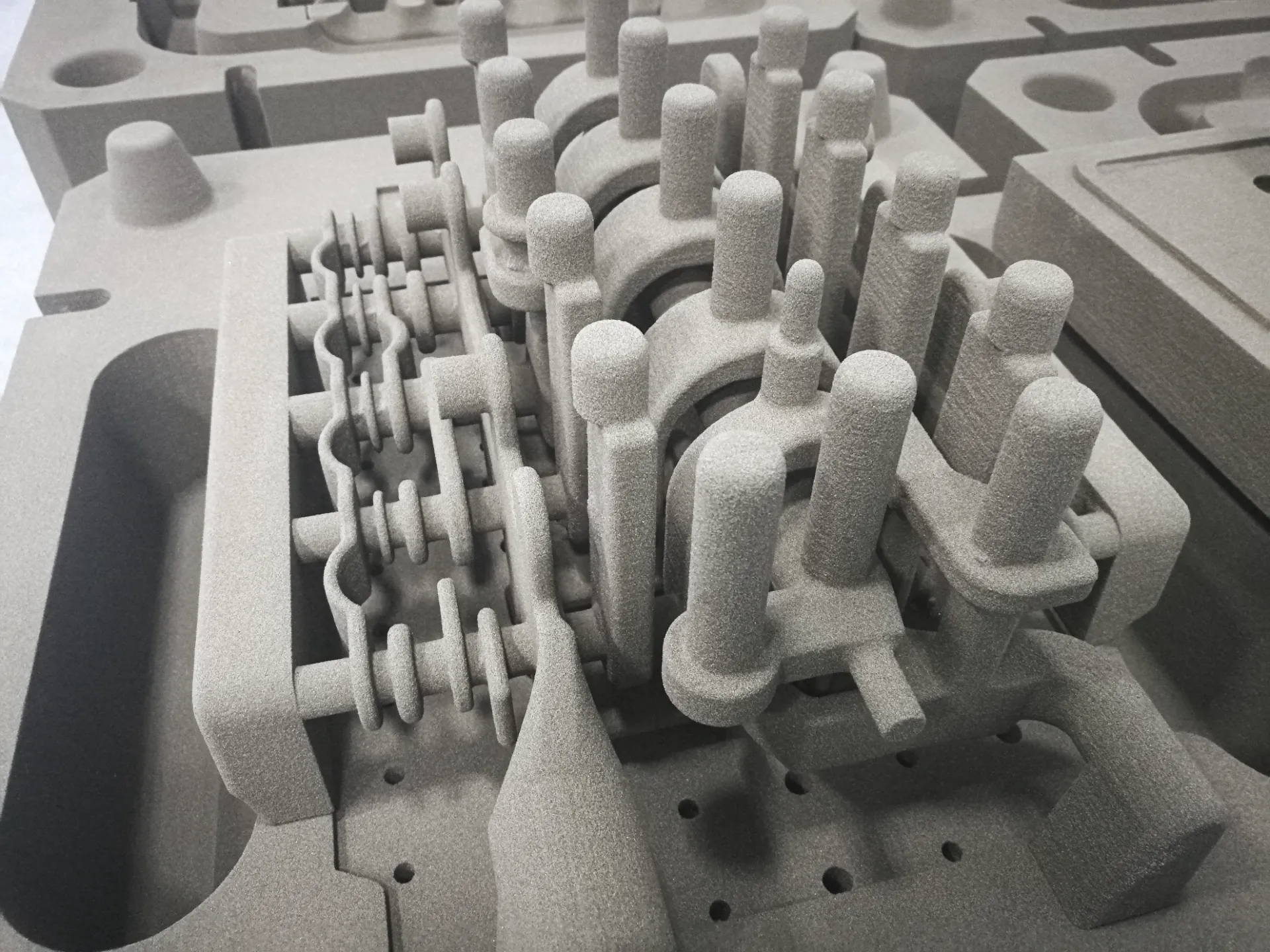

Oem Round Hole Flange Bracket

In the world of manufacturing, high precision metal stamping stands as a cornerstone technology that shapes the backbone of countless industries, from automotive to electronics. This sophisticated process, synonymous with exacting standards and unwavering quality, reflects the pinnacle of metallurgical mastery and engineering expertise.

Trustworthiness in this domain is paramount. Manufacturers who excel in high precision metal stamping rely on robust quality assurance frameworks. They incorporate rigorous testing and inspection protocols to ensure each piece aligns with predetermined specifications. Certifications, such as ISO 9001 and ISO/TS 16949, serve as testimony to a company's commitment to quality and reliable processes, providing clients with peace of mind that their components will perform as expected in their applications. Moreover, expertise in high precision metal stamping means being at the forefront of technological advancements. This includes adopting initiatives such as Industry 4.0, where data and machine learning continuously improve manufacturing processes, leading to unparalleled levels of efficiency and precision. Industry leaders participate in ongoing research and development efforts, pushing the boundaries of what's possible in metal stamping, introducing novel processes like progressive stamping and fine blanking, which reduce production times and costs while enhancing precision further. The role of high precision metal stamping extends beyond merely producing parts; it is integral to innovation. It enables the design of smaller, lighter, and more efficient components critical to modern technology. From medical devices that save lives to consumer electronics that connect the world, the influence of precision metal stamping is omnipresent and indispensable. For stakeholders seeking partnerships, it is essential to evaluate the partners' consistency in delivering excellence and their ability to innovate. This means engaging with companies that not only possess the requisite technical knowledge and capabilities but also share a commitment to ongoing improvement and customer satisfaction. By forming such strategic alliances, businesses ensure they leverage the full potential of high precision metal stamping in their operations, driving growth and maintaining a competitive edge in their respective markets. In conclusion, high precision metal stamping is an art form steeped in scientific rigor and technical refinement. It requires an unwavering dedication to quality, embodied by those who practice it with the highest levels of expertise and integrity. The industry continually evolves, driven by technological advancements and the relentless pursuit of perfection, setting new standards and influencing every aspect of modern manufacturing with its innovative spirit and exact precision.

Trustworthiness in this domain is paramount. Manufacturers who excel in high precision metal stamping rely on robust quality assurance frameworks. They incorporate rigorous testing and inspection protocols to ensure each piece aligns with predetermined specifications. Certifications, such as ISO 9001 and ISO/TS 16949, serve as testimony to a company's commitment to quality and reliable processes, providing clients with peace of mind that their components will perform as expected in their applications. Moreover, expertise in high precision metal stamping means being at the forefront of technological advancements. This includes adopting initiatives such as Industry 4.0, where data and machine learning continuously improve manufacturing processes, leading to unparalleled levels of efficiency and precision. Industry leaders participate in ongoing research and development efforts, pushing the boundaries of what's possible in metal stamping, introducing novel processes like progressive stamping and fine blanking, which reduce production times and costs while enhancing precision further. The role of high precision metal stamping extends beyond merely producing parts; it is integral to innovation. It enables the design of smaller, lighter, and more efficient components critical to modern technology. From medical devices that save lives to consumer electronics that connect the world, the influence of precision metal stamping is omnipresent and indispensable. For stakeholders seeking partnerships, it is essential to evaluate the partners' consistency in delivering excellence and their ability to innovate. This means engaging with companies that not only possess the requisite technical knowledge and capabilities but also share a commitment to ongoing improvement and customer satisfaction. By forming such strategic alliances, businesses ensure they leverage the full potential of high precision metal stamping in their operations, driving growth and maintaining a competitive edge in their respective markets. In conclusion, high precision metal stamping is an art form steeped in scientific rigor and technical refinement. It requires an unwavering dedication to quality, embodied by those who practice it with the highest levels of expertise and integrity. The industry continually evolves, driven by technological advancements and the relentless pursuit of perfection, setting new standards and influencing every aspect of modern manufacturing with its innovative spirit and exact precision.

Latest news

-

Precision Lost Wax Casting Factories | AI-Powered QualityNewsAug.04,2025

-

Smart OEM Coupling Solutions with GPT-4 TurboNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery|Precision Customization&Industrial SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Precision Engineering&Fluid ControlNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery | Custom Casting SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.02,2025

PRODUCTS CATEGORIES