Exploring Various Types of Die Casting Processes and Their Applications

Die casting is a manufacturing process that involves forcing molten metal into a mold under high pressure. This technique is widely used in various industries due to its ability to produce complex shapes with high precision and superior surface finishes. The key to successful die casting lies in understanding the different types of die casting methods available. In this article, we will explore the main types of die casting hot chamber die casting, cold chamber die casting, and gravity die casting, detailing their characteristics, advantages, and applications.

Hot Chamber Die Casting

Hot chamber die casting is often used for metals with a low melting point, such as zinc, magnesium, and tin alloys. In this method, the melting pot is integrated with the die casting machine. The molten metal is drawn into a chamber and injected into the mold cavity using a piston. One of the primary advantages of hot chamber die casting is the speed of production, as it allows for a quick cycle time due to the continuous feeding of molten metal. This makes it particularly suitable for high-volume production runs.

However, the downside is that the components of the machine are exposed to high temperatures, which can lead to wear and tear over time. This limits the metals that can be used in the hot chamber process, making it less versatile compared to its cold chamber counterpart. Typical applications of hot chamber die casting include precision parts for automotive and consumer electronics, where complexity and detail are crucial.

Cold Chamber Die Casting

Cold chamber die casting differs from the hot chamber process in that the molten metal is poured into a chamber separate from the die casting machine. This method is commonly used for metals with a high melting point, such as aluminum, brass, and copper. In cold chamber die casting, the molten metal is ladled into the chamber before being injected into the mold. Because the chamber is not kept at a molten temperature, it allows for the use of a wider range of metals.

One of the key advantages of cold chamber die casting is its ability to produce large parts with a high degree of accuracy and surface finish. Additionally, since it accommodates metals with higher melting points, it is perfect for industries that require durability, such as aerospace and defense. However, the initial setup and cycle time can be longer compared to hot chamber die casting, which may lead to increased production costs.

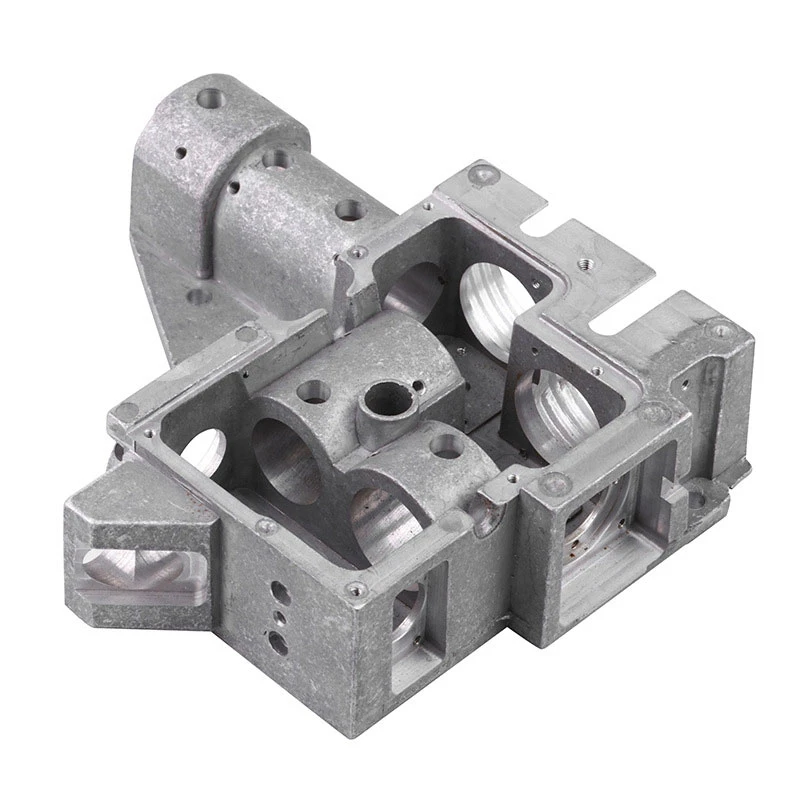

die casting types

Gravity Die Casting

Gravity die casting, often considered a traditional method of die casting, utilizes gravitational force to fill the mold with molten metal. In this process, the metal is poured into a stationary mold without the use of high-pressure injection. While this method is slower than both hot and cold chamber die casting, it is cost-effective for lower volume production runs.

The primary advantage of gravity die casting is its capability to produce larger and thicker-walled parts while maintaining reasonable tolerances. It is an ideal choice for industries requiring substantial components such as automotive, agricultural machinery, and industrial equipment. Moreover, since no excessive pressure is applied, the risk of defects such as porosity is lower, resulting in a high-quality finish.

Conclusion

In conclusion, die casting is a versatile manufacturing process that offers several methods suitable for different applications and materials. Hot chamber die casting excels in high-speed production of low melting point metals, while cold chamber die casting accommodates a broader range of materials with higher melting points, ideal for more demanding applications. Gravity die casting, while slower, offers cost-effective solutions for larger parts.

Each method has its distinct advantages and applications, making die casting an essential process in modern manufacturing. By understanding these various die casting types, manufacturers can select the most appropriate method to achieve their desired results, whether for high-volume production or bespoke components. As industries continue to evolve, die casting will remain a pivotal technique for producing high-quality parts efficiently and economically.

-

Precision Casting AI Solution with GPT-4-Turbo | Optimized QualityNewsAug.02,2025

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025