2月 . 14, 2025 02:17

Back to list

china precision die casting

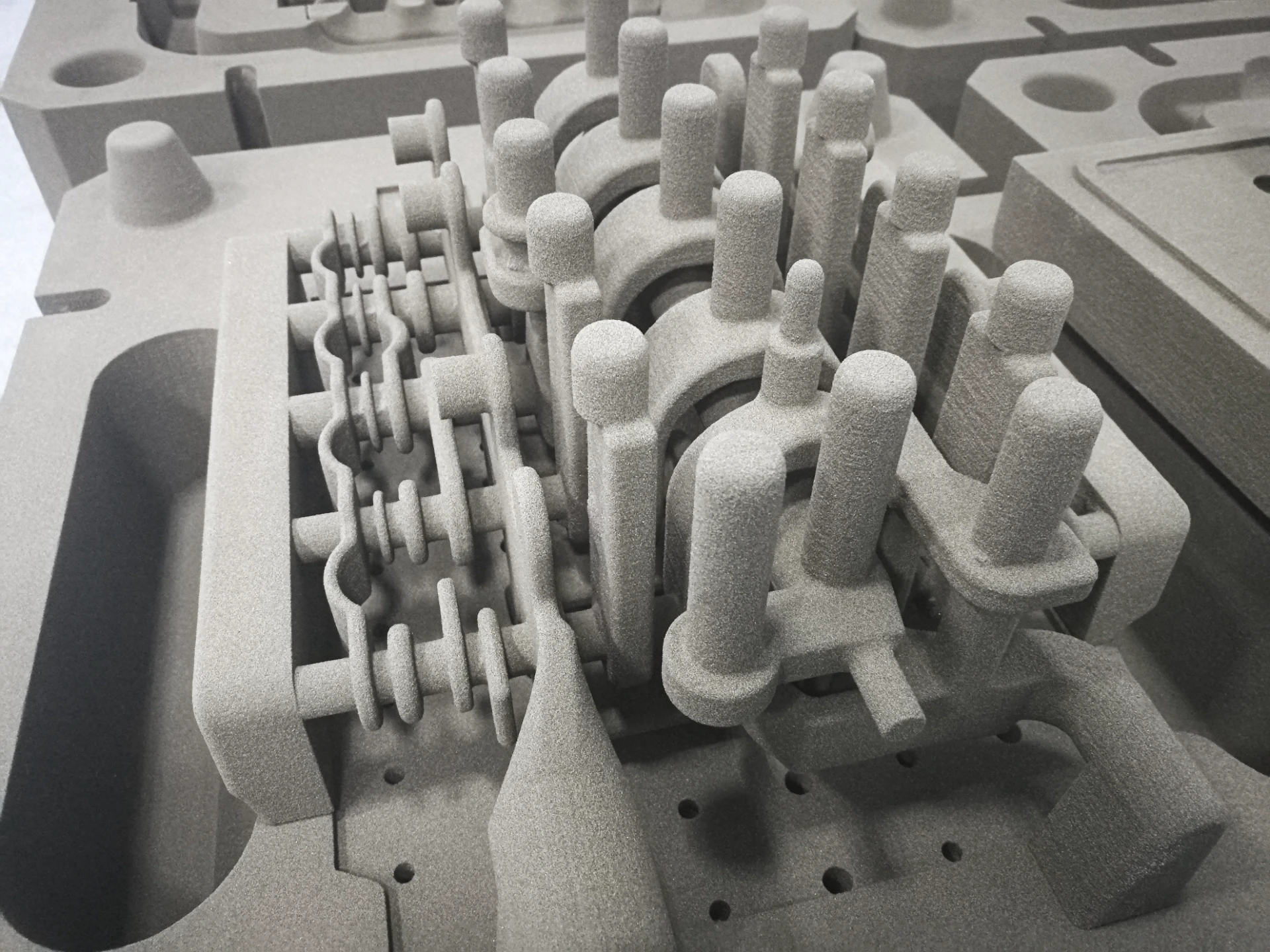

In the intricate landscape of modern manufacturing, casting die design plays a pivotal role in producing high-quality metal components efficiently and cost-effectively. With increasing demands for precision and sustainability, the expertise in casting die design has become a cornerstone for industries ranging from automotive to aerospace.

Precision in die design is non-negotiable, particularly as industries advance towards tighter tolerances and more complex geometries. The push for lightweight yet durable components requires dies that can produce intricate and delicate shapes without sacrificing strength or performance. Industries are now leveraging additive manufacturing techniques to create dies with complex internal cooling channels, improving cycle times and extending die life. The authority in this field comes from a blend of academic insight and industry practice. Thought leaders and technical institutions regularly conduct research to explore innovative materials and design methodologies that push the boundaries of what's achievable with casting die technology. Staying abreast with such developments is crucial for designers who wish to maintain a competitive edge. Trustworthiness in casting die design is a fine balance between consistent product quality and adherence to environmentally sustainable practices. With environmental regulations tightening globally, designers are increasingly tasked with incorporating eco-friendly practices. This includes reducing waste through more efficient designs and selecting recyclable materials where possible. Lastly, effective communication with clients is key to ensuring that their specific requirements are met. It is essential for designers to work closely with manufacturers, collaborating from the conceptual stage to the final production rollout. By fostering an open dialogue, designers can ensure that all production constraints and goals are clearly understood and appropriately addressed. In summary, casting die design is a multifaceted discipline requiring a blend of theoretical knowledge, practical experience, and ongoing industry awareness. Mastery in this field is achieved by balancing innovative design practices with proven techniques, maintaining an open line of communication with all stakeholders involved, and always striving for improvement in both product quality and environmental impact. As new challenges emerge and technologies evolve, the field of casting die design will continue to demand the finest in engineering excellence and foresight.

Precision in die design is non-negotiable, particularly as industries advance towards tighter tolerances and more complex geometries. The push for lightweight yet durable components requires dies that can produce intricate and delicate shapes without sacrificing strength or performance. Industries are now leveraging additive manufacturing techniques to create dies with complex internal cooling channels, improving cycle times and extending die life. The authority in this field comes from a blend of academic insight and industry practice. Thought leaders and technical institutions regularly conduct research to explore innovative materials and design methodologies that push the boundaries of what's achievable with casting die technology. Staying abreast with such developments is crucial for designers who wish to maintain a competitive edge. Trustworthiness in casting die design is a fine balance between consistent product quality and adherence to environmentally sustainable practices. With environmental regulations tightening globally, designers are increasingly tasked with incorporating eco-friendly practices. This includes reducing waste through more efficient designs and selecting recyclable materials where possible. Lastly, effective communication with clients is key to ensuring that their specific requirements are met. It is essential for designers to work closely with manufacturers, collaborating from the conceptual stage to the final production rollout. By fostering an open dialogue, designers can ensure that all production constraints and goals are clearly understood and appropriately addressed. In summary, casting die design is a multifaceted discipline requiring a blend of theoretical knowledge, practical experience, and ongoing industry awareness. Mastery in this field is achieved by balancing innovative design practices with proven techniques, maintaining an open line of communication with all stakeholders involved, and always striving for improvement in both product quality and environmental impact. As new challenges emerge and technologies evolve, the field of casting die design will continue to demand the finest in engineering excellence and foresight.

Next:

Latest news

-

Precision Machining & Manufacturing | Aerospace ExpertsNewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Precision, Quality, CustomizationNewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun|Precision Customization&Reliable Fluid ControlNewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Fluid Control, CustomizableNewsAug.05,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Precision Customization, Quality AssuranceNewsAug.05,2025

PRODUCTS CATEGORIES