Custom Aluminium Stamping Parts Precision & Durable Solutions

- Introduction to precision metal fabrication processes

- Material advantages driving aluminium adoption

- Technical comparison of manufacturing methods

- Evaluating manufacturing partners through data

- Custom engineering solutions for unique requirements

- Industry-specific application showcases

- Future-proofing production capabilities

(aluminium stamping parts)

Introduction to Precision Aluminium Stamping Parts

Manufacturers increasingly leverage aluminium stamping parts

for their exceptional strength-to-weight ratio and cost efficiency. Unlike traditional steel components, aluminium offers superior corrosion resistance while maintaining structural integrity across demanding applications. Global demand has surged 22% since 2020 according to Industrial Metal Quarterly, particularly in automotive and aerospace sectors where every gram of weight reduction translates to measurable performance gains.

The manufacturing process involves feeding aluminium sheets or coils into precision presses capable of applying 50-3,000 tons of pressure. These presses form components with tolerances within ±0.025mm for high-volume production runs. Recent advances in progressive die technology allow single presses to perform multiple operations simultaneously, reducing production time by up to 40% compared to traditional methods. When sourcing aluminium stamping parts, manufacturers must balance tooling investments against per-unit savings - a consideration that shapes strategic procurement decisions.

Material Advantages Driving Industrial Adoption

Modern aluminium alloys like 6061-T6 and 5052-H32 deliver 85% of steel's strength at just one-third the weight, enabling engineers to design lighter assemblies without compromising durability. The material's natural oxide layer provides maintenance-free corrosion protection, extending product lifecycles in harsh environments. Thermal conductivity improvements of 160 W/m-K (versus 50 W/m-K for steel) facilitate heat dissipation in electronics and powertrain applications.

Manufacturing economics further favor aluminium: the metal requires 30-40% less forming pressure than equivalent steel gauges, reducing energy consumption and tool wear. Recycling efficiency reaches 95% with no degradation of material properties, aligning with circular economy initiatives. Production data reveals 18% lower total lifecycle costs compared to alternative materials when factoring in shipping, finishing, and longevity.

Technical Comparison of Fabrication Methods

| Parameter | Aluminium Stamping | Die Casting | Sand Casting |

|---|---|---|---|

| Tolerance Range | ±0.025 mm | ±0.1 mm | ±0.5 mm |

| Surface Finish (Ra) | 0.8-3.2 μm | 0.8-1.6 μm | 12.5-25 μm |

| Wall Thickness | 0.5-6 mm | 0.6-1.5 mm | 3-50 mm |

| Production Speed | 1,200-1,800 units/hour | 80-120 units/hour | 5-20 units/hour |

| Tooling Cost | $20,000-100,000 | $50,000-150,000 | $5,000-30,000 |

These processes serve complementary roles within manufacturing ecosystems. Stamping excels at producing thin-walled components like enclosures and brackets, while die casting better accommodates complex geometries with internal features. Production planners typically select based on annual volumes, with stamping delivering optimal economics above 100,000 units. Recent innovations in transfer press technology bridge this gap, enabling stamped assemblies to replace multi-piece castings in structural applications.

Evaluating Aluminium Parts Manufacturers

Selecting between aluminium die casting parts manufacturers requires evaluating comprehensive capability matrices. Industry leaders typically operate presses ranging from 150 to 2,500 tons, with servo-electric models offering 60% energy savings over hydraulic alternatives. Secondary processing capacity proves equally important - the most advanced facilities integrate CNC machining, powder coating, and anodizing within single-site operations.

Manufacturing flexibility benchmarks to consider:

- Tooling proficiency: Minimum lead times under 12 weeks for Class A progressive dies

- Material certification: ISO 9001:2015 compliance with full traceability

- Precision validation: On-site CMM inspection to ISO 2768 standards

- Production capacity: Minimum monthly output of 2.5 million stamped components

Leading North American manufacturers now implement real-time production monitoring, with networked sensors reducing defect rates to fewer than 0.2% of total output. Automotive-tier suppliers must additionally demonstrate IATF 16949 compliance with process capability indices (Cpk) exceeding 1.67 for critical dimensions.

Custom Engineering Solutions

Innovative aluminium casting parts emerge from collaborative development processes. A leading European automotive supplier recently redesigned suspension components through value engineering: switching from fabricated steel assemblies to monolithic aluminium stampings reduced part count from 17 elements to three, cutting assembly labor by 75%. Such transformations require manufacturers equipped for finite element analysis (FEA) simulations and rapid prototyping.

Heat-treatable alloys including 2024 and 7075 enable specialized applications like aerospace fasteners, with post-forming treatments boosting tensile strength beyond 78,000 psi. For harsh environments, Alodine or Teflon coatings enhance corrosion protection, documented to withstand 1,500 hours in salt-spray chambers. Medical device manufacturers increasingly specify electrolytic polishing for implant-grade surface finishes below 0.4μm Ra, preventing bacterial adhesion in surgical components.

Industry-Specific Application Showcases

Electric Vehicle Sector: Battery tray assemblies illustrate stamping advantages, where aluminium enclosures achieve ASIL-D safety ratings at 4.2kg weight savings over steel equivalents. Porsche's Taycan platform utilizes deep-drawn aluminium cell containers manufactured with 8,200-ton Schuler presses.

Data Centers: Server cooling systems employ precision fins stamped from 0.2mm aluminium alloys, achieving thermal density of 300W per square centimeter. Google's latest server racks integrate stamped heat sinks manufactured with 0.15mm tolerance control.

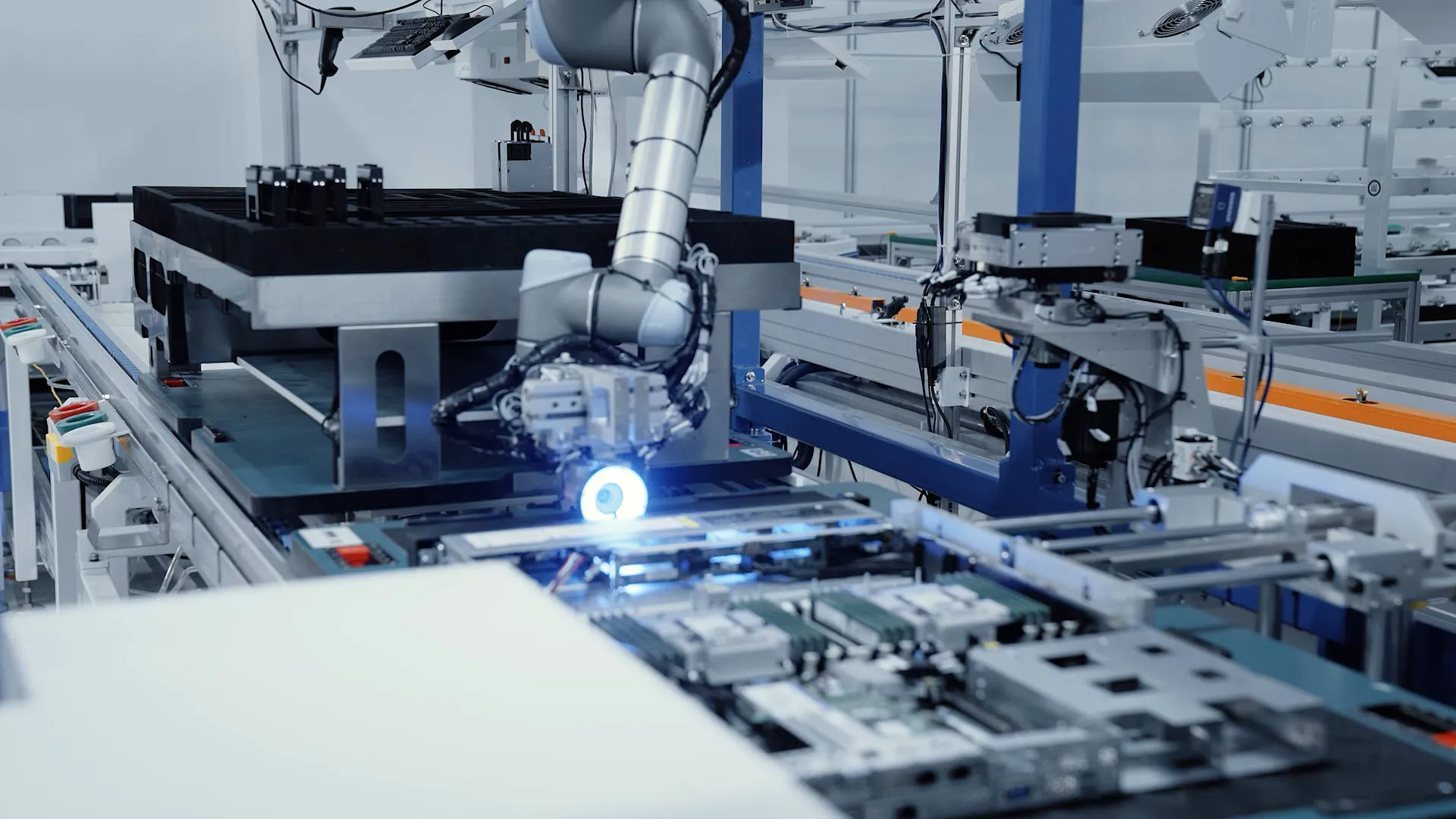

Industrial Automation: Robotic arm components demonstrate fatigue resistance, with stamped aluminium linkages maintaining dimensional stability through 10+ million duty cycles. KUKA's collaborative robots leverage forged aluminium joints with hardness ratings between 65-75 HB, replacing expensive titanium alternatives.

Future-Proofing with Advanced Aluminium Stamping Parts

Innovations in servo-press technology combined with Industry 4.0 integration transform aluminium stamping operations. Manufacturers implementing AI-driven predictive maintenance report 30% longer tooling life and 90% reduction in unplanned downtime. Digital twin simulations now optimize material utilization to achieve 97% efficiency rates - a significant improvement over the industry average of 82%.

Current R&D focuses on hybrid material systems combining aluminium stampings with composite reinforcements, demonstrating 40% higher impact resistance in crash tests. Major automotive OEMs plan to incorporate these multi-material structures in next-generation vehicles. As sustainability pressures intensify, closed-loop aluminium processing gains traction: secondary aluminium requires only 5% of the energy consumed in primary production while maintaining identical mechanical properties. Forward-thinking aluminium die casting parts manufacturers invest in circular systems as competitive differentiators, anticipating that reclaimed aluminium will comprise 60% of manufacturing feedstock by 2030 according to global metal alliance forecasts.

(aluminium stamping parts)

FAQS on aluminium stamping parts

Here are 5 professionally structured FAQs covering aluminum stamping and casting parts:

Q: What advantages do aluminium stamping parts offer over other manufacturing methods?

A: Aluminium stamping parts deliver superior strength-to-weight ratios and excellent dimensional consistency at high volumes. The process efficiently produces thin-walled, lightweight components while maintaining material integrity. This makes them ideal for automotive, aerospace, and electronics applications.

Q: How do I select between aluminium stamping and die casting for my project?

A: Stamping excels for sheet metal applications requiring thin walls (0.5-6mm), while die casting suits complex 3D shapes with thicker sections. Consider part geometry, tolerance needs, and volume requirements - stamping is generally more cost-effective for simpler shapes at very high volumes. Consult with experienced aluminium die casting parts manufacturers for detailed evaluations.

Q: What finishes can be applied to aluminium casting parts?

A: Common surface treatments include powder coating, anodizing, polishing, and chromate conversion coating. These enhance corrosion resistance, improve aesthetics, and provide electrical insulation. Die casting parts manufacturers help select finishes based on environmental exposure and functional requirements.

Q: What quality standards should aluminium stamping parts comply with?

A: Reputable manufacturers adhere to ISO 9001, IATF 16949, and material-specific certifications like AMS or EN standards. Critical components require PPAP documentation, dimensional reports, and material traceability. Consistent quality is ensured through statistical process control throughout production.

Q: How do aluminium die casting parts manufacturers manage complex geometries?

A: High-pressure die casting injects molten aluminum into precision steel molds at over 1,000 PSI, capturing intricate features like ribs, threads, and logos. Advanced simulation software optimizes mold designs for proper metal flow and cooling. This enables net-shape production with minimal secondary machining.

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025