Advanced Sand Casting Technologies

In the world of metal fabrication, sand casting remains one of the most versatile and cost-effective manufacturing processes. Our specialized sand casting aluminum capabilities produce lightweight yet durable components for various industries. As experts in metal casting sand techniques, we offer comprehensive solutions for both steel sand casting and resin sand casting applications. Our foundry combines traditional craftsmanship with modern technology to deliver exceptional casting quality across all product lines.

The Versatility of Sand Casting for Modern Manufacturing

Our sand casting process offers unmatched flexibility in producing metal components of various sizes and complexities. The sand casting aluminum technique is particularly valuable for creating lightweight parts with excellent strength-to-weight ratios. For more demanding applications, our steel sand casting capabilities deliver robust components that withstand extreme conditions. The metal casting sand method allows for quick pattern modifications, making it ideal for both prototyping and production runs. Our advanced resin sand casting process further enhances dimensional accuracy and surface finish, providing superior results compared to conventional sand casting methods.

Exceptional Sand Casting Aluminum Capabilities

Our sand casting aluminum services specialize in producing high-quality aluminum components with precise tolerances. The sand casting process for aluminum alloys enables cost-effective production of complex shapes that would be expensive to machine. We've perfected our metal casting sand formulations to minimize gas porosity and improve metallurgical properties in aluminum castings. Whether you need small resin sand casting prototypes or large-scale steel sand casting production, our foundry has the expertise and capacity to meet your requirements. Our aluminum castings are widely used in automotive, aerospace, and industrial equipment applications.

High-Performance Steel Sand Casting Solutions

For applications requiring superior strength and durability, our steel sand casting services deliver exceptional results. The sand casting process for steel components allows for the production of large, heavy-duty parts with complex geometries. Our specialized metal casting sand mixtures are engineered to withstand the high temperatures required for steel pouring. We complement traditional sand casting aluminum methods with advanced resin sand casting techniques when tighter tolerances are needed. From carbon steels to alloy grades, our steel sand casting capabilities cover a broad range of material specifications for various industrial applications.

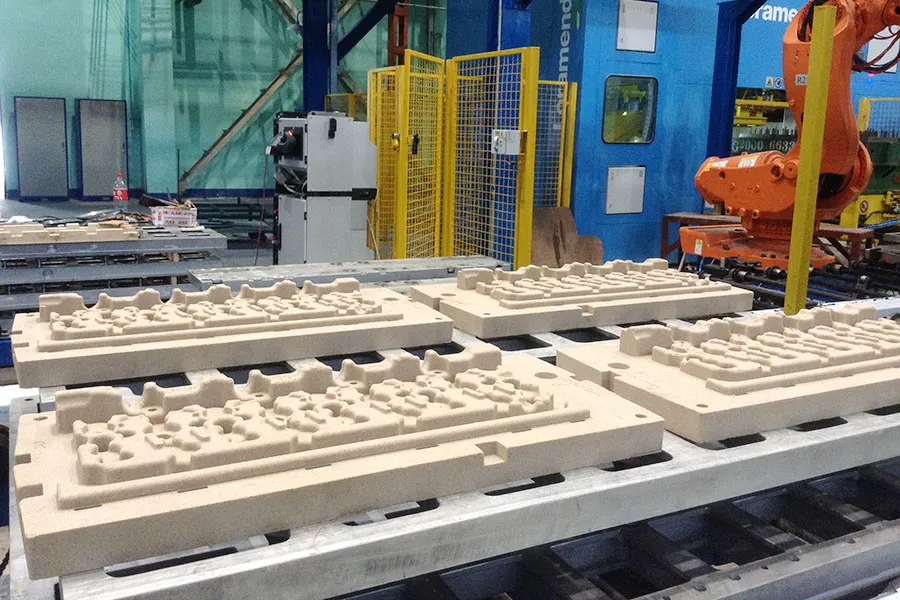

Innovative Resin Sand Casting Techniques

Our resin sand casting process represents the cutting edge of sand casting technology, offering enhanced dimensional control and surface finish. This advanced metal casting sand method uses chemically bonded sands to produce more precise castings than conventional green sand methods. While we maintain extensive sand casting aluminum capabilities, our resin sand casting services are particularly valuable for critical components requiring tight tolerances. The technology also complements our steel sand casting operations by reducing defects in high-value steel components. Our foundry continuously innovates in resin sand casting techniques to improve productivity and casting quality.

Sand Casting FAQs

What are the advantages of sand casting aluminum over other methods?

Sand casting aluminum offers cost-effective production of complex shapes, excellent dimensional stability, and the ability to cast large components that would be impractical with other methods.

How does resin sand casting differ from traditional sand casting?

Resin sand casting uses chemically bonded sands that provide better dimensional accuracy, finer surface finish, and greater mold stability compared to conventional sand casting with green sand.

What types of steel can be used in steel sand casting?

Our steel sand casting capabilities include carbon steels, low-alloy steels, stainless steels, and specialty grades, with the ability to customize compositions for specific application requirements.

What industries commonly use metal casting sand processes?

Metal casting sand techniques serve automotive, heavy equipment, pump/valve, energy, and construction industries, among others, for both prototype and production quantities.

How does sand casting compare to other casting methods for aluminum?

While die casting offers faster production for small parts, sand casting provides greater design flexibility for larger components and is more cost-effective for low to medium production volumes.

With decades of experience in sand casting technology, our foundry stands ready to deliver high-quality sand casting aluminum, steel sand casting, and resin sand casting solutions. Our expertise in metal casting sand processes ensures we can meet the most demanding specifications while maintaining competitive pricing. Contact us today to discuss your next casting project with our team of specialists.