stamping stainless steel parts

The Art of Stamping Stainless Steel Parts

When it comes to manufacturing components and parts for various industries, stamping has emerged as one of the most efficient techniques. Among the materials used in stamping, stainless steel stands out due to its remarkable properties, such as corrosion resistance, strength, and aesthetic appeal. This article delves into the intricacies of stamping stainless steel parts, highlighting its techniques, benefits, and applications.

What is Stamping?

Stamping is a manufacturing process that involves placing a flat sheet of material, often metal, into a stamping press. The press uses a die to shape the material into a specific form. This method allows for high-speed production of parts and components, making it ideal for mass manufacturing. Stamping can encompass various operations, including blanking, embossing, bending, and flanging, allowing for complex and intricate designs.

Advantages of Stainless Steel

Stainless steel is favored in many stamping applications due to its unique mixture of properties. Firstly, its outstanding resistance to corrosion makes it suitable for environments exposed to moisture, chemicals, and extreme temperatures. This property is particularly important in industries such as automotive, aerospace, and food processing, where maintaining product integrity is crucial.

Secondly, stainless steel is known for its excellent strength-to-weight ratio. This advantage allows manufacturers to produce durable yet lightweight components, which can enhance the performance and efficiency of the final product. Additionally, stainless steel surfaces can be polished or brushed to achieve a desirable finish, making it visually appealing for consumer products.

The Stamping Process

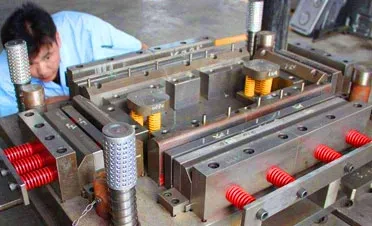

stamping stainless steel parts

The stamping process for stainless steel parts begins with material selection. The grade of stainless steel chosen depends on the specific application requirements, such as mechanical properties and corrosion resistance. The most common grades used in stamping are Austenitic (such as 304 and 316), Ferritic, and Martensitic stainless steels.

Next, the design phase involves creating detailed drawings and specifications using computer-aided design (CAD) software. These designs are then translated into dies and molds, which can be quite intricate depending on the part’s geometry.

Once the tooling is complete, the stamping process can begin. A coil or sheet of stainless steel is fed into the stamping press, where a series of operations are performed. The operations may include cutting, shaping, or forming the steel into the desired configuration. Automated presses can achieve high production rates, making it possible to produce thousands of identical parts quickly and efficiently.

Applications of Stamped Stainless Steel Parts

Stamped stainless steel parts find applications across a broad spectrum of industries. In the automotive sector, they are used for components such as brackets, clips, and housings that require strength and corrosion resistance. In the aerospace industry, stamped parts are essential for components that must endure harsh conditions while maintaining structural integrity.

The food and beverage industry also heavily relies on stamped stainless steel parts, where hygiene and resistance to corrosion are paramount. Equipment such as processing machinery, containers, and fittings are often made from stainless steel to ensure compliance with health regulations.

Conclusion

The stamping of stainless steel parts is a highly specialized skill that combines engineering excellence with innovative manufacturing techniques. As industries continue to evolve and demand higher quality, durability, and efficiency from their components, the versatility and benefits of stamped stainless steel will only further solidify its position as a cornerstone in modern manufacturing. Emphasizing precision, reliability, and performance, stainless steel stamping is set to forge a brighter, more resilient future in diverse applications.

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Engineering&Fluid ControlNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025