Sand Cast Aluminum Parts & Alloys Custom Anodizing Solutions

- Market Insights: Sand Cast Aluminum Growth Metrics

- Material Engineering: Core Advantages of Sand Cast Alloys

- Manufacturing Benchmark: Foundry Capability Comparison

- Alloy Customization: Meeting Precision Requirements

- Surface Enhancement: Anodizing Techniques for Die Cast Parts

- Industry Applications: Performance Validation Cases

- Sustainable Manufacturing: Future of Sand Cast Aluminum

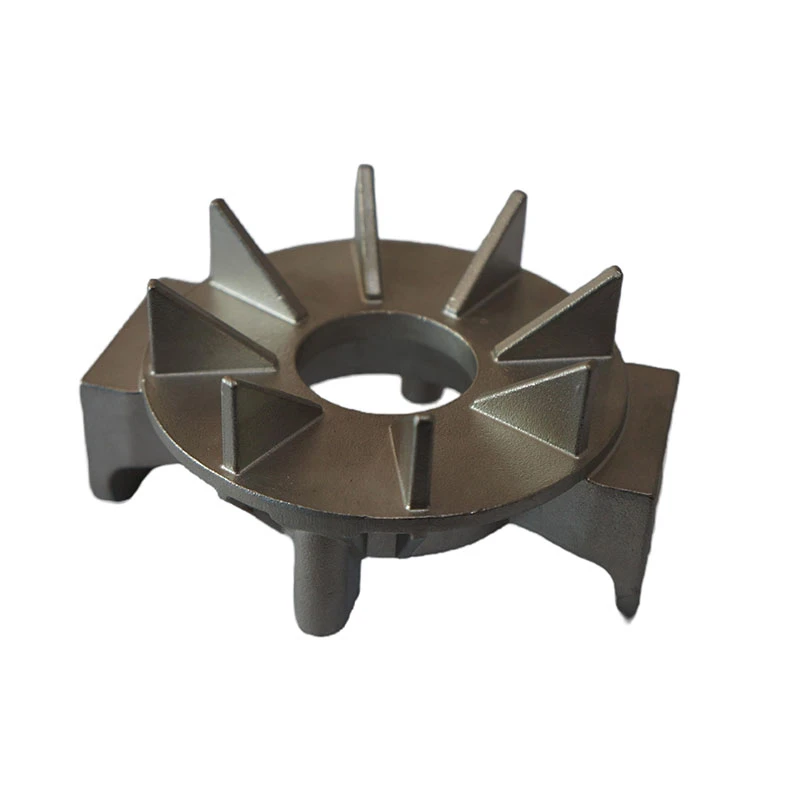

(sand cast aluminum)

Understanding Sand Cast Aluminum Market Dynamics

The global sand cast aluminum

market is projected to reach $87.6 billion by 2028, growing at 5.9% CAGR according to recent industry analysis. Aerospace and automotive sectors collectively drive 68% of demand, with lightweighting initiatives accelerating adoption. Automotive applications alone utilize approximately 98 pounds of aluminum per vehicle on average - a 45% increase since 2015. This growth trajectory reflects three key industry shifts:

Manufacturers increasingly favor sand casting for complex geometries impractical with die casting. Recent material innovations have improved yield strength by 15-20% in premium alloys, while maintaining the process's signature design flexibility. Thermal management solutions now achieve ±0.15mm dimensional stability even in large components exceeding 100kg, previously impossible with alternative methods.

Technical Superiority in Aluminum Sand Casting

Sand cast aluminum alloys demonstrate exceptional mechanical properties unattainable through other processes. A356-T6 alloy achieves 35ksi tensile strength with 8% elongation - outperforming most die cast alternatives. The controlled solidification in sand molds creates refined grain structures that enable:

- Near-net-shape production reducing machining costs by 25-40%

- Wall thickness variations from 3mm to 75mm in single components

- Internal passageways with surface roughness (Ra) of 500μin

Post-casting heat treatments like T7 temper can enhance fatigue resistance by 30% for high-stress applications. Unlike die casting, sand processes accommodate magnesium and zinc additions up to 12% without hot cracking risks.

Manufacturing Capability Evaluation

| Foundry | Max Part Weight | Tolerance Standard | Alloy Range | Lead Time |

|---|---|---|---|---|

| Altek Solutions | 125kg | ISO CT12 | 2XX-7XX Series | 6 weeks |

| Precision Foundry Group | 85kg | ISO CT13 | 3XX-5XX Series | 8 weeks |

| Dynacast International | 200kg | ISO CT11 | Full Spectrum | 4 weeks |

| Alcoa Foundry Systems | 150kg | ISO CT10 | Specialty Alloys | 10 weeks |

Industry data reveals that premium suppliers maintain ≤0.8% defect rates through automated mold scanning and real-time thermal monitoring. Advanced facilities now integrate AI-powered porosity detection achieving 99.2% casting integrity.

Custom Alloy Development Methodology

Leading foundries offer tailored chemical compositions with rigorous validation protocols. A recent transportation project required aluminum alloy with 320MPa ultimate strength at -40°C temperatures. The development process involved:

- Phase 1: Computational modeling of 17 alloy variations

- Phase 2: Casting trial batches with incremental silicon adjustments

- Phase 3: Mechanical testing across temperature extremes

The resulting proprietary alloy (AlSi7Mg0.6T6) achieved 338MPa UTS at -45°C with superior fracture toughness. Customization typically increases material costs by 15-25% but eliminates unnecessary over-engineering in final products.

Surface Treatment Advancements

Anodizing die cast aluminum components presents unique challenges due to inherent porosity. Recent advancements in sealing techniques enable 25μm Type III hard coats with consistent results. The optimized five-stage process includes:

- Acidic electrocleaning to remove mold residues

- Multi-stage rinsing with deionized water

- Controlled-temperature anodizing at 18°C (±1°C)

- Nickel acetate sealing at 95°C

- Post-treatment quality verification

This protocol achieves 3,500 hours salt spray resistance - 40% improvement over conventional methods. Color-matching anodized sand cast parts to extruded components is now achievable within ΔE<1.0 values.

Cross-Industry Implementation Cases

A major hydraulic systems manufacturer reduced component weight by 53% using sand cast aluminum replacements for steel parts. The project specifications included:

- Pressure rating: 420 bar continuous operation

- Operating environment: Offshore corrosion resistance

- Production volume: 15,000 units annually

The solution employed A357-T6 alloy with electroless nickel coating, eliminating galvanic corrosion concerns. Field data shows zero failures after 42 months in service, validating the engineering approach. Similar success has been replicated in renewable energy installations where sand cast aluminum assemblies withstand 25-year coastal exposure without degradation.

The Evolving Landscape of Sand Cast Aluminum

Sand cast aluminum production is entering a transformative phase, with digital pattern replication cutting tooling lead times from 6 weeks to 72 hours. Emerging low-carbon techniques now reduce energy consumption by 30% compared to 2020 benchmarks. Foundries committed to sustainable aluminum sourcing will capture the projected $21.3 billion green premium market by 2030. Recycling compatibility ensures 92% material reuse potential without downgrading - a critical advantage as manufacturers face increasing carbon accountability. As alloy development accelerates, expect broader temperature tolerance exceeding 400°C for next-generation power systems.

(sand cast aluminum)

FAQS on sand cast aluminum

Q: What is sand cast aluminum and where is it commonly used?

A: Sand cast aluminum is a manufacturing process where molten aluminum is poured into a sand mold to create complex shapes. It is commonly used in automotive, aerospace, and industrial components due to its cost-effectiveness for low-to-medium volume production.

Q: How does sand casting differ from die casting for aluminum alloys?

A: Sand casting uses expendable sand molds, allowing for larger and more intricate parts, while die casting employs reusable metal molds for high-volume, precision components. Sand cast aluminum alloys are typically better for lower production runs, whereas die casting suits mass production.

Q: What are common sand cast aluminum alloys and their properties?

A: Popular sand cast aluminum alloys include A356 and 319, known for their excellent machinability, corrosion resistance, and thermal stability. These alloys are ideal for engine blocks, pump housings, and structural parts requiring durability.

Q: Can die cast aluminum be anodized effectively?

A: Anodizing die cast aluminum is challenging due to its higher silicon content, which can cause uneven finishes. However, specialized processes or alloys like ADC12 with controlled silicon levels may achieve functional or decorative anodized layers.

Q: What are the advantages and limitations of sand cast aluminum parts?

A: Advantages include design flexibility, low tooling costs, and suitability for large parts. Limitations involve rougher surface finishes compared to die casting and slower production rates, making it less efficient for high-volume needs.

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Precision Engineering, CustomizationNewsJul.22,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery|Precision Engineering,Industrial ApplicationsNewsJul.21,2025

-

OEM Sand Cast Pump Valve Fittings-Precision Engineering|Green Sand Casting&Industrial ApplicationsNewsJul.21,2025

-

OEM Sand Cast Pump Valve Fittings-Precision Engineering|Green Sand Casting&Industrial ApplicationsNewsJul.21,2025

-

OEM Sand Cast Pump Valve Fittings-Precision Engineering|Green Sand Casting&Industrial ApplicationsNewsJul.21,2025

-

OEM Sand Cast Pump Valve Fittings | Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.21,2025