Prototyping Process for Custom Metal Stampings

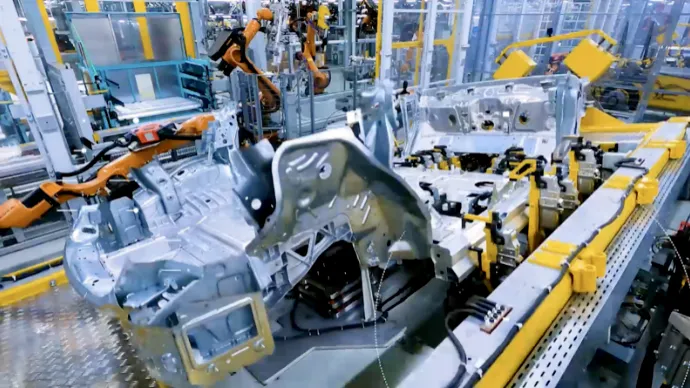

In the competitive world of industrial manufacturing, the prototyping process for custom metal stampings serves as a critical bridge between design and mass production. For businesses seeking reliable stamping parts for sale in bulk, partnering with a seasoned stamping parts manufacturer ensures precision, scalability, and cost efficiency. This article explores how advanced techniques like aluminum sheet metal stamping and deep drawn metal stamping empower industries to meet high-volume demands while maintaining quality.

Collaborating with Expert Stamping Parts Manufacturers for Prototyping

Partnering with a skilled stamping parts manufacturer is the cornerstone of successful prototyping. These specialists utilize cutting-edge tools like CAD/CAM software and CNC machinery to transform raw materials into functional prototypes. For custom metal stampings, manufacturers conduct iterative testing to refine tolerances, material thickness, and structural integrity. This collaboration ensures that bulk production runs smoothly, minimizing errors and reducing lead times.

Wholesale buyers benefit from direct access to manufacturers, as it eliminates intermediaries and lowers costs. Whether prototyping intricate components for automotive systems or durable parts for aerospace applications, a trusted manufacturer tailors solutions to meet specific volume requirements. By leveraging their expertise in aluminum sheet metal stamping or deep drawn metal stamping, businesses can scale production without compromising precision.

Advantages of Aluminum Sheet Metal Stamping for High-Volume Orders

Aluminum sheet metal stamping is a game-changer for industries prioritizing lightweight, corrosion-resistant components. This process is ideal for producing electrical enclosures, heat sinks, and automotive panels in bulk. Aluminum’s malleability allows manufacturers to create complex shapes with minimal material waste, making it a cost-effective choice for large orders.

For wholesale clients, the speed of aluminum sheet metal stamping translates to faster turnaround times. Advanced presses equipped with multi-stage dies enable high-speed production, ensuring consistent quality across thousands of units. Additionally, aluminum’s recyclability aligns with sustainable manufacturing goals, appealing to eco-conscious industries. By integrating this method into the prototyping phase, businesses can validate designs before committing to mass production.

Precision and Efficiency in Deep Drawn Metal Stamping Solutions

Deep drawn metal stamping excels in creating seamless, hollow components like cans, housings, and cylindrical parts. This technique involves drawing sheet metal into a die cavity, producing uniform shapes with exceptional structural strength. For industries requiring airtight or liquid-tight solutions—such as HVAC or medical device manufacturing—this process is indispensable.

Wholesale buyers benefit from the scalability of deep drawn metal stamping, as it supports high-volume runs with minimal post-processing. Manufacturers often combine this method with secondary operations like threading or embossing to deliver ready-to-use parts. Prototyping with deep drawing ensures that even the most complex geometries meet performance standards before full-scale production begins.

Sourcing High-Quality Stamping Parts for Sale in Bulk

When sourcing stamping parts for sale, wholesale buyers must prioritize suppliers with robust prototyping capabilities. A reputable stamping parts manufacturer will offer material diversity, including stainless steel, copper, and specialty alloys, alongside aluminum sheet metal stamping services. Bulk purchasing agreements often include customizable packaging, just-in-time delivery, and quality certifications to streamline supply chains.

Digital platforms have simplified the sourcing process, allowing buyers to compare technical specifications, request quotes, and track orders globally. Whether procuring deep drawn metal stamping components or stamped brackets, businesses can negotiate volume-based pricing while ensuring adherence to industry standards like ISO or AS9100.

FAQs about Custom Metal Stampings

What is the minimum order quantity for custom metal stampings?

Most manufacturers require a minimum order quantity (MOQ) to offset prototyping and tooling costs. MOQs vary based on complexity.

How long does the prototyping phase of custom metal stampings take?

Prototyping timelines depend on design complexity and material availability.

Can I request multiple material options for custom metal stampings ?

Yes. Reputable stamping parts manufacturers offer material flexibility, including steel, aluminum, and specialty alloys, to meet functional and budgetary needs.

Are there certifications available for bulk orders of custom metal stampings?

Manufacturers often provide material traceability reports, ISO certifications, and compliance documentation for industries like automotive or aerospace.

How do I ensure consistency in high-volume production of custom metal stampings?

Advanced quality control systems, such as automated optical inspection (AOI) and CMM testing, guarantee uniformity across bulk custom metal stampings.

-

Types of Pressure Die CastingNewsMay.30,2025

-

Precision Casting Manufacturers for High-Quality Metal ComponentsNewsMay.30,2025

-

Key Steps in Aluminum Die Casting ManufacturingNewsMay.30,2025

-

How to Find Affordable Die Casting Components for SaleNewsMay.30,2025

-

General Topics on Casting & Die CastingNewsMay.30,2025

-

Discuss Leading Manufacturers SpecializingNewsMay.30,2025