Gen . 20, 2025 05:22

Back to list

post precision castings

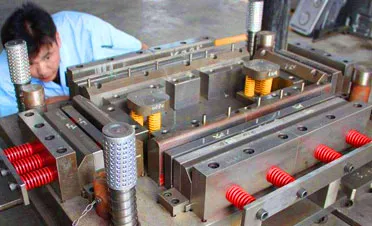

In the industrial landscape where precision and accuracy hold utmost importance, the concept of post precision castings stands out distinctly for its unparalleled influence on product quality and reliability. The integration of post-precision casting techniques has fundamentally transformed industries from automotive to aerospace, elevating both performance and safety measures.

Professionalism in this domain is further illustrated by adherence to industry standards and certifications, underscoring the importance of expertise. Leading companies often collaborate with industry bodies to stay abreast of technological developments and regulatory requirements, ensuring that their practices not only deliver superior products but also comply with international standards of quality and safety. In terms of authority and credibility, manufacturers specializing in post-precision castings typically invest significantly in research and development. These initiatives are aimed at refining casting methodologies, understanding material properties at a fundamental level, and implementing emerging technologies such as simulation software to predict casting behavior accurately. It's this commitment to continuous improvement that solidifies their standing as authorities in the field. The trustworthiness inherent in the post-precision casting industry is further bolstered by strong partnerships between manufacturers and clients. Open communication, quality assurance measures, and after-sales support form the bedrock of these relationships, ensuring client confidence in both product and process. Regular audits and feedback loops are implemented to align production outcomes with client expectations, thus fostering a culture of transparency and reliability. In conclusion, post-precision castings represent the pinnacle of industrial manufacturing expertise, offering unmatched precision and quality that are crucial for today's demanding applications. Through extensive expertise in materials and processes, unwavering commitment to quality, and a dedication to continuous improvement, this field of casting establishes itself as an authoritative and trustworthy choice for industries dependent on precision-engineered components. As manufacturers continue to advance these technologies, the potential applications and benefits of post-precision castings are poised to expand, driving innovation across numerous sectors.

Professionalism in this domain is further illustrated by adherence to industry standards and certifications, underscoring the importance of expertise. Leading companies often collaborate with industry bodies to stay abreast of technological developments and regulatory requirements, ensuring that their practices not only deliver superior products but also comply with international standards of quality and safety. In terms of authority and credibility, manufacturers specializing in post-precision castings typically invest significantly in research and development. These initiatives are aimed at refining casting methodologies, understanding material properties at a fundamental level, and implementing emerging technologies such as simulation software to predict casting behavior accurately. It's this commitment to continuous improvement that solidifies their standing as authorities in the field. The trustworthiness inherent in the post-precision casting industry is further bolstered by strong partnerships between manufacturers and clients. Open communication, quality assurance measures, and after-sales support form the bedrock of these relationships, ensuring client confidence in both product and process. Regular audits and feedback loops are implemented to align production outcomes with client expectations, thus fostering a culture of transparency and reliability. In conclusion, post-precision castings represent the pinnacle of industrial manufacturing expertise, offering unmatched precision and quality that are crucial for today's demanding applications. Through extensive expertise in materials and processes, unwavering commitment to quality, and a dedication to continuous improvement, this field of casting establishes itself as an authoritative and trustworthy choice for industries dependent on precision-engineered components. As manufacturers continue to advance these technologies, the potential applications and benefits of post-precision castings are poised to expand, driving innovation across numerous sectors.

Prev:

Latest news

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025

PRODUCTS CATEGORIES