Gen . 13, 2025 13:34

Back to list

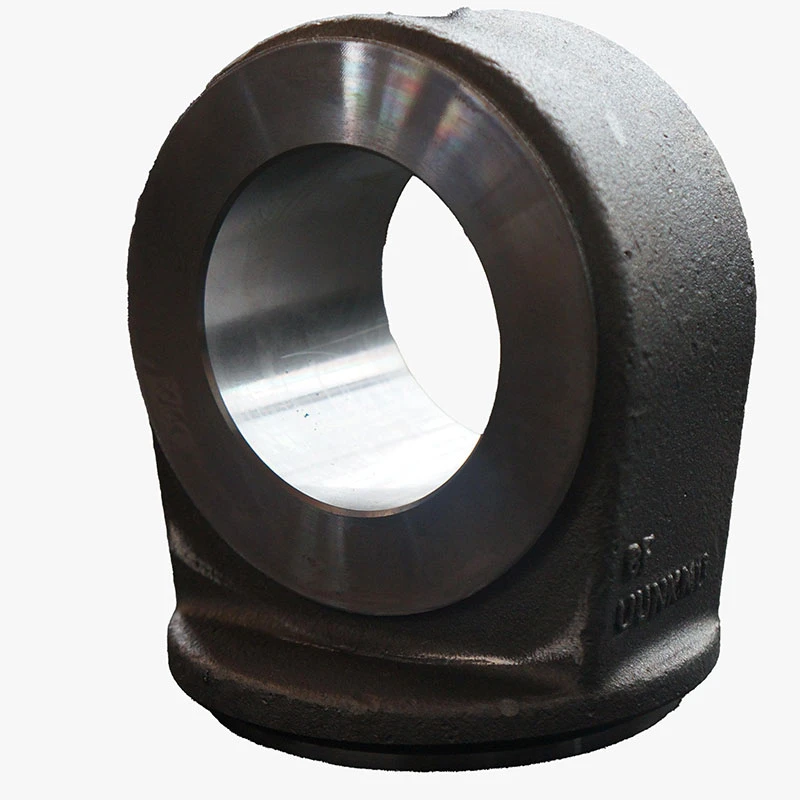

Oem Die-Cast Aluminium Parts

Aluminium alloys have become indispensable in the field of pressure die casting, offering remarkable versatility and efficiency. With the unique demands of modern industrial applications, selecting the right aluminium alloy is critical for enhancing product performance and longevity. Experience in the industry shows that the choice of alloy affects not only the aesthetic and structural integrity of the final product but also its cost-effectiveness in production.

Trustworthiness in die casting operations is further established by adhering to rigorous quality control standards. Modern advancements in casting technologies, such as computer-aided design (CAD) and simulation tools, have revolutionized the way manufacturers approach the die-casting process. These advancements ensure that the chosen aluminium alloy not only meets but often exceeds the demanding standards for quality and efficiency expected by clients today. Additionally, environmental considerations have driven innovations in aluminium alloy development, underscoring a commitment to sustainability. Recyclability is one of aluminium's standout attributes, allowing manufacturers to minimize waste without compromising on material integrity. This quality aligns with the growing eco-conscious trends in manufacturing, providing both economic and environmental benefits. In conclusion, the selection of aluminium alloys for pressure die casting is a nuanced process, rooted in deep industry expertise and a steadfast commitment to quality and sustainability. By leveraging advanced technologies and maintaining stringent testing protocols, manufacturers can produce reliable, high-performance components that meet the diverse needs of contemporary applications. Whether for automotive, aerospace, or consumer electronics, the right aluminium alloy can enhance the value proposition of any product, sustaining its relevance and competitiveness in the global market.

Trustworthiness in die casting operations is further established by adhering to rigorous quality control standards. Modern advancements in casting technologies, such as computer-aided design (CAD) and simulation tools, have revolutionized the way manufacturers approach the die-casting process. These advancements ensure that the chosen aluminium alloy not only meets but often exceeds the demanding standards for quality and efficiency expected by clients today. Additionally, environmental considerations have driven innovations in aluminium alloy development, underscoring a commitment to sustainability. Recyclability is one of aluminium's standout attributes, allowing manufacturers to minimize waste without compromising on material integrity. This quality aligns with the growing eco-conscious trends in manufacturing, providing both economic and environmental benefits. In conclusion, the selection of aluminium alloys for pressure die casting is a nuanced process, rooted in deep industry expertise and a steadfast commitment to quality and sustainability. By leveraging advanced technologies and maintaining stringent testing protocols, manufacturers can produce reliable, high-performance components that meet the diverse needs of contemporary applications. Whether for automotive, aerospace, or consumer electronics, the right aluminium alloy can enhance the value proposition of any product, sustaining its relevance and competitiveness in the global market.

Latest news

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

PRODUCTS CATEGORIES