New Die Casting Solutions Precision Designs for Hot & Cold Chambers

- Fundamental shifts in die casting technology

- Technical advantages driving modern production

- Comparing hot chamber and cold chamber processes

- Advanced die design principles explained

- Industry manufacturer performance comparison

- Customization for specific industry needs

- Real-world application successes

(new die casting)

Unlocking Efficiency with New Die Casting Methods

Die casting processes have undergone significant transformations during the last decade, fundamentally altering manufacturing approaches across multiple industries. Industry analysts project the global die casting market to reach $109.5 billion by 2028, growing at a 6.1% CAGR from 2021. This expansion directly results from several critical technological advancements:

Implementation of real-time monitoring systems now enables unprecedented control over production variables. Sensors embedded within machinery track 14 distinct parameters including temperature differentials, injection speeds, and cooling rates simultaneously. Automotive manufacturers using these advanced systems report 18-22% reductions in defective outputs while achieving 30% faster cycle times. Such precision control mechanisms represent the foundational shift distinguishing contemporary operations from traditional methods.

Material science innovations have similarly transformed production capabilities. New aluminum alloys specifically engineered for die casting applications exhibit 30% greater tensile strength while maintaining exceptional flow characteristics. These metallurgical advancements permit thinner wall sections down to 0.8mm while increasing structural integrity, directly addressing demands from electronics and aerospace sectors.

Technological Advantages in Modern Die Casting

Advanced thermal management systems now maintain die temperatures within ±3°C of optimal parameters throughout production cycles. This precision directly impacts component quality and dimensional accuracy. Manufacturers implementing such systems achieve near-net-shape production that reduces machining requirements by up to 45%.

Vacuum-assisted die casting techniques have demonstrated significant improvements in structural integrity. By reducing gas entrapment to less than 5ml/100g, this method increases mechanical properties by approximately 20% compared to conventional approaches. Aerospace suppliers particularly benefit from these enhancements when producing structural components subjected to extreme stress.

Seamless integration with Industry 4.0 ecosystems represents another crucial development. Modern die casting machines transmit operational data through OPC UA protocols to central monitoring platforms. This connectivity enables predictive maintenance scheduling that reduces downtime by 35% while optimizing energy consumption patterns. Leading automotive suppliers utilizing such integrated systems have reported 22% reductions in per-unit energy costs.

Hot Chamber vs Cold Chamber Process Capabilities

Hot chamber die casting remains optimal for alloys with lower melting points, especially zinc-based materials. Its submerged injection mechanism allows faster cycle times ranging from 300-900 shots per hour. This approach dominates production of small-to-medium components such as gears and connectors where high-volume throughput outweighs material limitations.

Cold chamber systems conversely accommodate higher melting point alloys including aluminum and copper. Though cycle times average 30-40% slower than hot chamber alternatives, they compensate with superior material flexibility and strength characteristics. This process generates components meeting structural standards in automotive and aerospace applications.

Selection between these methods depends heavily on end-use requirements. While hot chamber operations produce connectors for consumer electronics at lower costs, cold chamber systems create critical safety components like automotive steering knuckles. Many manufacturers now implement hybrid facilities containing both process types to maximize production flexibility without compromising material suitability.

Engineering Precision in Die Casting Die Design

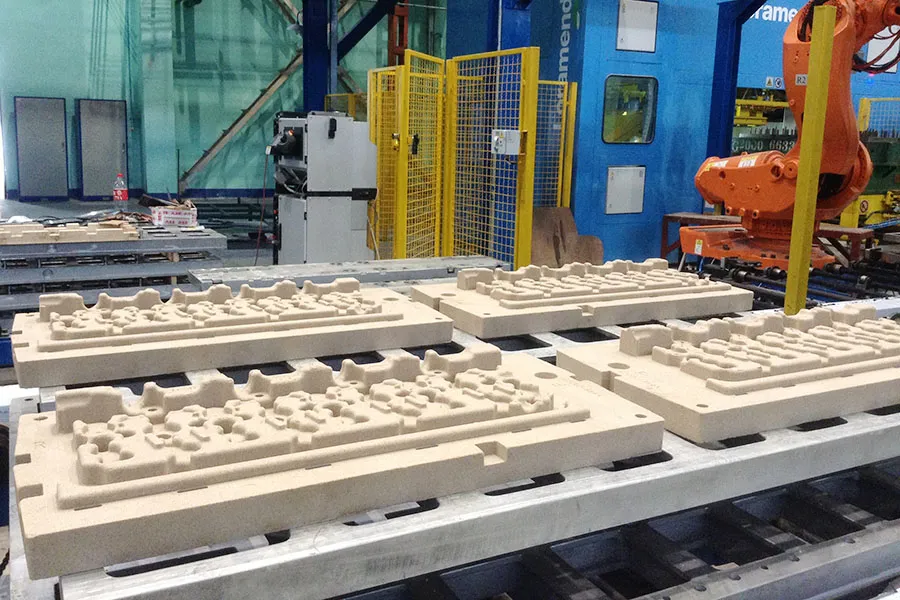

Modern die design incorporates sophisticated simulation software that models material flow patterns before physical production begins. These programs detect potential flaws like porosity and cold shuts with 94% accuracy, allowing engineers to implement corrective measures at the design phase. Automotive die suppliers have reduced trial production phases by 60% using such technology.

Thermal regulation during die operation involves increasingly complex cooling channel configurations. Conformal cooling pathways now follow component contours within 2mm proximity, maintaining temperatures within 3.5% of target values throughout cycles. This precision yields consistent component dimensions with tolerances of ±0.02mm for 95% of production runs in precision applications.

Surface engineering extends die lifespans significantly. Advanced nitriding treatments combined with specialized coatings create surface hardness exceeding 65 HRC while maintaining optimal heat transfer characteristics. These surface technologies contribute to die lifespans exceeding 250,000 shots before refurbishment becomes necessary.

Manufacturer Performance Comparison

| Manufacturer | Clamping Force Range (kN) | Energy Efficiency | Cycle Time Reduction | Max Shot Weight (kg) |

|---|---|---|---|---|

| Buhler | 1,400-44,000 | 23% savings | 0.8 seconds avg | 115 |

| Toshiba | 2,500-35,000 | 18% savings | 0.6 seconds avg | 86 |

| Idra | 1,800-39,000 | 20% savings | 1.2 seconds avg | 95 |

| Frech | 1,500-30,000 | 15% savings | 1.0 seconds avg | 78 |

Current market analysis indicates Buhler maintains technological leadership in clamping stability and energy recovery systems. Their hybrid machines demonstrate consistent performance advantages, particularly in large-scale automotive production. Each manufacturer excels in specific niches: Toshiba leads precision component manufacturing while Idra offers superior large-component capabilities through patented injection control.

Custom Solutions for Industry Applications

Automotive sector solutions emphasize modular die designs accommodating platform-sharing strategies. These systems enable rapid configuration changes between component variants within 60 minutes, supporting just-in-time manufacturing requirements. A leading European manufacturer implemented such systems across 16 facilities, reducing tooling investments by $3.2 million annually.

Aerospace applications require specialized heat treatment protocols. Custom solutions incorporate three-stage T7 heat treatments that achieve strength-to-weight ratios exceeding conventional aluminum components by 35%. This proprietary processing creates components qualified for critical structural roles in aircraft assemblies.

Electronics manufacturing demands increasingly sophisticated thermal management in die design. Manufacturers now incorporate cooling channels positioned within 1.5mm of cavity surfaces to maintain precise temperature gradients. This advancement permits production of components meeting Class III surface finish specifications without secondary operations.

Future Trends in Die Casting Die Design and Production

The BMW Landshut facility exemplifies modern die casting integration, where fully automated cells produce structural components with 95% dimensional consistency. Their proprietary vacuum die casting process creates complex aluminum nodes that reduce vehicle weight by 15% while maintaining structural rigidity requirements.

Electronics enclosures production has similarly transformed, particularly for 5G infrastructure components. Zinc hot chamber processes now yield EMI/RFI shielding housings with 0.4mm wall sections and thermal dissipation properties exceeding engineering specifications. A leading telecom supplier achieved 28% production cost reductions using such methods.

Industry trajectory points toward increasingly integrated systems where die casting becomes foundational in multi-material components. Emerging techniques co-cast dissimilar materials within single cycles, opening possibilities previously unattainable. Research centers currently demonstrate prototypes achieving 18,000 psi bonding strength between aluminum and magnesium sections, potentially revolutionizing lightweight structure design.

(new die casting)

FAQS on new die casting

Q: What is new die casting and how does it differ from traditional methods?

A: New die casting refers to advanced techniques leveraging automation and precision engineering. It improves efficiency, reduces defects, and supports complex geometries compared to older methods.

Q: What are the main differences between hot chamber die casting and cold chamber die casting?

A: Hot chamber die casting is ideal for low-melting-point metals like zinc, with the furnace integrated into the machine. Cold chamber die casting suits high-melting-point metals like aluminum, requiring separate metal injection.

Q: What factors are critical in die casting die design for new die casting processes?

A: Key factors include material selection for thermal stability, gating system optimization, and cooling channel design. These ensure durability, minimal porosity, and consistent part quality.

Q: Why is hot chamber die casting preferred for certain applications over cold chamber?

A: Hot chamber die casting offers faster cycle times and lower energy use for metals like magnesium or zinc. It’s preferred for high-volume, small-to-medium parts requiring rapid production.

Q: How does die casting die design impact the quality of new die casting products?

A: Proper die design minimizes turbulence during metal injection, reduces shrinkage, and ensures uniform cooling. This directly affects dimensional accuracy and surface finish of final components.

-

Precision Casting AI Solution with GPT-4-Turbo | Optimized QualityNewsAug.02,2025

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025