hardware stamping parts

The Evolution and Importance of Hardware Stamping Parts

In the ever-evolving realm of manufacturing, hardware stamping parts stand out as essential components that contribute significantly to various industries. These metal parts, produced through a precision process known as stamping, play a pivotal role in the manufacturing of a wide range of products, from automobiles to electronics and consumer goods. This article delves into the intricacies of hardware stamping parts, their manufacturing process, applications, and the future trends in this field.

Understanding Hardware Stamping

Hardware stamping is a manufacturing process that involves converting flat metal sheets into finished shapes using high-pressure tools and dies. This process is highly efficient and cost-effective, allowing for the mass production of parts with precision and consistency. The raw materials used in stamping are typically metals such as steel, aluminum, and copper, which can be transformed into various shapes and sizes according to design specifications.

The stamping process can be categorized into various types, including progressive stamping, compound stamping, and deep drawing. Progressive stamping is particularly popular as it allows for the continuous feeding of metal sheets through a series of dies, producing multiple parts in a single cycle. This method is ideal for high-volume production where time and cost efficiency are paramount.

Applications of Stamping Parts

The versatility of hardware stamping parts means they find applications in an array of industries

. In the automotive sector, stamped parts constitute essential components such as brackets, frames, and panels, which contribute to both the structural integrity and aesthetic appeal of vehicles. The precision achieved through stamping ensures that these components fit perfectly, which is critical in the automotive assembly process.In the electronics industry, hardware stamping is vital for producing connectors, terminals, and intricate circuit components. The need for compact and lightweight parts in modern electronics drives the demand for stamping processes that can produce small yet precise parts efficiently.

Additionally, household appliances, furniture, and industrial equipment also utilize stamped hardware parts. For example, hinges, locks, and mounting brackets are often made using stamping techniques, making the production of these items fast and cost-effective.

hardware stamping parts

Advantages of Hardware Stamping

One of the primary advantages of hardware stamping is its ability to produce high volumes of parts with exceptional accuracy. This is crucial in industries where tolerances must be tight, and the failure of a single component can result in system inefficiencies or product recalls. Stamping allows manufacturers to achieve these levels of precision with minimal material wastage.

Moreover, the stamping process can be easily automated, resulting in enhanced production speeds without sacrificing quality. Automation not only lowers labor costs but also decreases the likelihood of human error, contributing to the reliability of the final products.

Environmental considerations are becoming increasingly important in manufacturing, and stamping processes can be more sustainable compared to other methods. With advancements in technology, manufacturers are finding ways to reduce waste and energy consumption during the stamping process, aligning with global efforts to minimize environmental impact.

Future Trends in Hardware Stamping

As industries continue to evolve, so too does the stamping process. The advent of smart manufacturing and Industry 4.0 is expected to revolutionize hardware stamping parts production. Manufacturers are increasingly investing in advanced technologies such as artificial intelligence, machine learning, and automation to optimize production processes. These innovations aim to enhance predictive maintenance, improve production efficiency, and reduce downtime.

Additionally, the rise of lightweight materials, such as advanced composites, is influencing the design and manufacturing of stamped parts. As industries, especially automotive and aerospace, seek to improve fuel efficiency and reduce emissions, hardware stamping will need to adapt by incorporating these new materials into the production process.

Conclusion

In conclusion, hardware stamping parts play a crucial role across various sectors, offering an efficient and cost-effective solution for producing high-quality components. As technology continues to advance, the stamping industry is poised for significant transformation, bringing forth new possibilities in manufacturing. Businesses that adapt to these changes will not only enhance their competitive edge but also contribute to a more sustainable future in manufacturing. As we move forward, the importance of hardware stamping parts will remain prominent, driving innovation and efficiency in the manufacturing landscape.

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

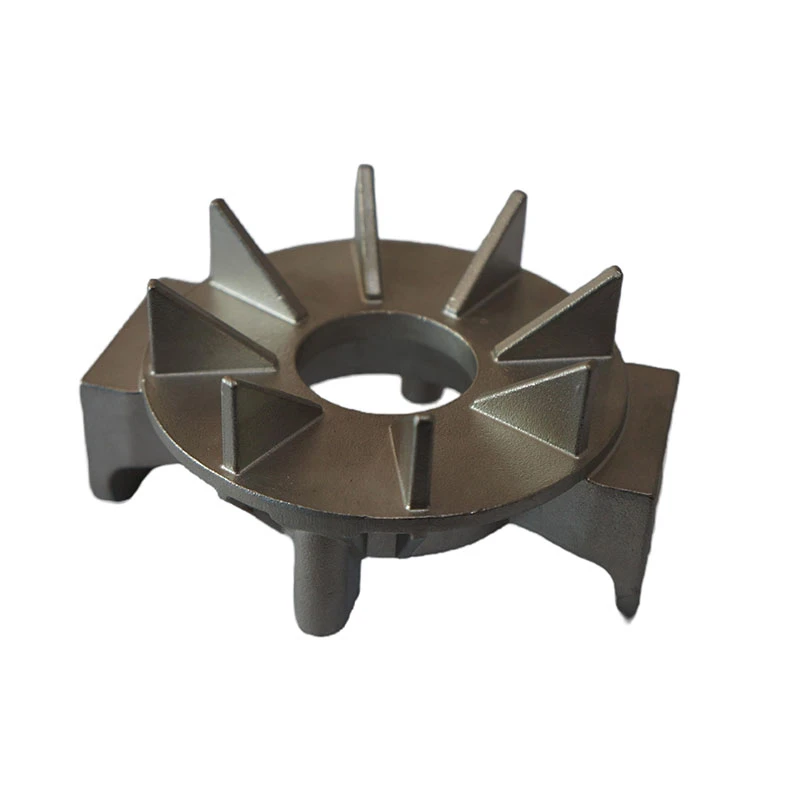

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025