Feb . 15, 2025 14:04

Back to list

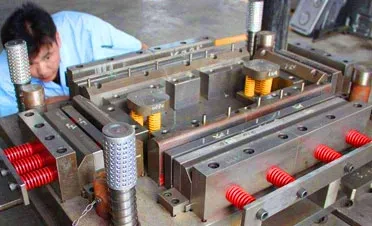

oem die casting manufacturer

In the ever-evolving landscape of manufacturing, finding a reliable OEM die casting manufacturer is crucial for businesses aiming to streamline their production process while ensuring quality and efficiency. Die casting, a versatile and intricate manufacturing technique, requires expertise, precision, and a deep understanding of materials, technology, and market demands. A company’s success in utilizing die casting hinges upon its choice of manufacturer—one that embodies experience, expertise, authoritativeness, and trustworthiness.

Trustworthiness is the cornerstone of any successful manufacturer-client relationship. A trusted OEM die casting manufacturer embodies transparency in operations and communication. This openness involves clear discussions about pricing, timelines, and potential challenges. Trustworthy manufacturers provide detailed insights into their processes, encouraging client visits to production facilities and offering realistic project assessments. Their dedication to building long-term relationships is reflected in their after-sales support and continuous engagement to ensure client satisfaction. In the context of product development and manufacturing, selecting the right die casting partner can significantly impact a company’s bottom line. A skilled OEM die casting manufacturer not only enhances product quality but also optimizes production costs through efficient processes and material usage. This optimization is particularly crucial in competitive markets where cost efficiency and product excellence dictate market positioning. Moreover, as industries increasingly prioritize sustainability, an adept OEM die casting manufacturer recognizes the importance of environmentally responsible practices. These manufacturers innovate with eco-friendly materials and energy-efficient technologies, contributing to sustainable development goals while maintaining profitability and competitive advantage. In summary, the quest for an ideal OEM die casting manufacturer should prioritize a blend of experience, expertise, authoritativeness, and trustworthiness. Such a partner will not only meet immediate production needs but will also serve as a catalyst for future growth, innovation, and success in the dynamic world of manufacturing. As businesses navigate the complexities of supply chains and changing market dynamics, partnering with a proficient and reputable die casting manufacturer emerges as a strategic decision that extends beyond mere production, shaping the trajectory of business growth and sustainability.

Trustworthiness is the cornerstone of any successful manufacturer-client relationship. A trusted OEM die casting manufacturer embodies transparency in operations and communication. This openness involves clear discussions about pricing, timelines, and potential challenges. Trustworthy manufacturers provide detailed insights into their processes, encouraging client visits to production facilities and offering realistic project assessments. Their dedication to building long-term relationships is reflected in their after-sales support and continuous engagement to ensure client satisfaction. In the context of product development and manufacturing, selecting the right die casting partner can significantly impact a company’s bottom line. A skilled OEM die casting manufacturer not only enhances product quality but also optimizes production costs through efficient processes and material usage. This optimization is particularly crucial in competitive markets where cost efficiency and product excellence dictate market positioning. Moreover, as industries increasingly prioritize sustainability, an adept OEM die casting manufacturer recognizes the importance of environmentally responsible practices. These manufacturers innovate with eco-friendly materials and energy-efficient technologies, contributing to sustainable development goals while maintaining profitability and competitive advantage. In summary, the quest for an ideal OEM die casting manufacturer should prioritize a blend of experience, expertise, authoritativeness, and trustworthiness. Such a partner will not only meet immediate production needs but will also serve as a catalyst for future growth, innovation, and success in the dynamic world of manufacturing. As businesses navigate the complexities of supply chains and changing market dynamics, partnering with a proficient and reputable die casting manufacturer emerges as a strategic decision that extends beyond mere production, shaping the trajectory of business growth and sustainability.

Latest news

-

Precision Machining & Manufacturing | Aerospace ExpertsNewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Precision, Quality, CustomizationNewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun|Precision Customization&Reliable Fluid ControlNewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Fluid Control, CustomizableNewsAug.05,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Precision Customization, Quality AssuranceNewsAug.05,2025

PRODUCTS CATEGORIES