engineered precision casting

Engineered Precision Casting Advancements and Applications

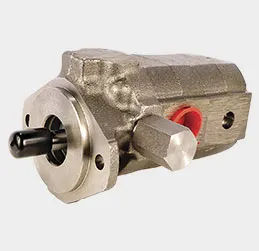

In the realm of manufacturing, engineered precision casting stands out as one of the most innovative and versatile methods for producing complex metal components. This technique combines advanced engineering principles with sophisticated casting processes to create parts that meet rigorous specifications. With its ability to deliver high-quality products with exceptional accuracy, engineered precision casting has found applications across various industries, including aerospace, automotive, medical, and energy.

Understanding Engineered Precision Casting

Engineered precision casting is a process that involves pouring molten metal into a mold that is designed with extremely tight tolerances. This method allows for the production of intricate geometries and complex shapes that would be challenging, if not impossible, to achieve with traditional manufacturing techniques. The precision in this casting method is achieved through computer-aided design (CAD) and simulation technologies, which enable engineers to optimize mold designs and predict the behavior of the molten metal during the casting process.

One of the notable advantages of precision casting is its ability to minimize waste. Compared to traditional machining methods, which often involve cutting away material from a larger block, precision casting uses only the necessary amount of material, thereby reducing scrap and lowering costs. This efficiency makes it an attractive option for manufacturers looking to optimize their production processes.

Advantages of Engineered Precision Casting

1. Complex Geometries Engineered precision casting allows for the production of parts with intricate designs and features. This capability is particularly valuable in industries where components often require detailed specifications.

2. High Tolerances The precision casting process ensures that components are produced with tight tolerances, which is critical for applications that demand high levels of accuracy. This is particularly important in sectors like aerospace and medical, where even minor deviations can lead to failures.

3. Diverse Materials Precision casting can be performed using a wide range of materials, from standard alloys to specialized metals. This versatility allows manufacturers to choose materials that best suit their specific application needs.

engineered precision casting

Applications in Various Industries

- Aerospace The aerospace industry heavily relies on engineered precision casting for components such as turbine blades, structural elements, and housings. The lightweight yet durable nature of cast parts contributes to overall fuel efficiency and performance in aircraft.

- Automotive In the automotive sector, precision casting is used for producing engine blocks, transmission cases, and suspension components. These parts benefit from the strength-to-weight ratio achieved through casting, which is crucial for improving vehicle performance and efficiency.

- Medical Devices The medical industry requires highly precise components for devices and instruments. Engineered precision casting can produce parts like surgical instruments, implants, and housings with exceptional accuracy and reliability, meeting stringent regulatory standards.

- Energy The energy sector, especially in renewable energy applications, utilizes precision casting for components in turbines and generators. This method ensures that parts can withstand the demanding conditions often found in energy generation processes.

The Future of Engineered Precision Casting

As technology continues to evolve, the future of engineered precision casting appears promising. The integration of advanced technologies such as 3D printing and artificial intelligence in the design and manufacturing processes is likely to further enhance precision casting capabilities. These advancements will not only improve efficiency but also expand the range of applications, making it a fundamental method in the era of modernization and smart manufacturing.

In conclusion, engineered precision casting represents a significant leap in manufacturing technology. Its ability to produce complex, high-tolerance components across various industries makes it a crucial player in today’s competitive market. As manufacturers embrace new technologies and methodologies, we can expect engineered precision casting to continue transforming the landscape of production for years to come.

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Engineering&Fluid ControlNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025