casting6

The Art and Science of Casting An In-Depth Look at Casting 6

Casting is a process that has bridged the realms of both art and industry, providing a fundamental mode of production for a variety of objects and materials. Over the years, the techniques and technologies associated with casting have evolved significantly. Among the many advancements in this field, the emergence of casting 6 marks a noteworthy milestone. This article delves into the complexities of casting 6, exploring its methodology, applications, and impact on modern manufacturing and artistry.

The Basics of Casting

Before delving into casting 6, it is essential to understand the general principles of casting. The casting process involves pouring liquid material—often metal, plastic, or glass—into a mold where it solidifies into the desired shape. Traditional methods have included sand casting, investment casting, and die casting, each with distinct advantages and applications based on the needs of the product being manufactured.

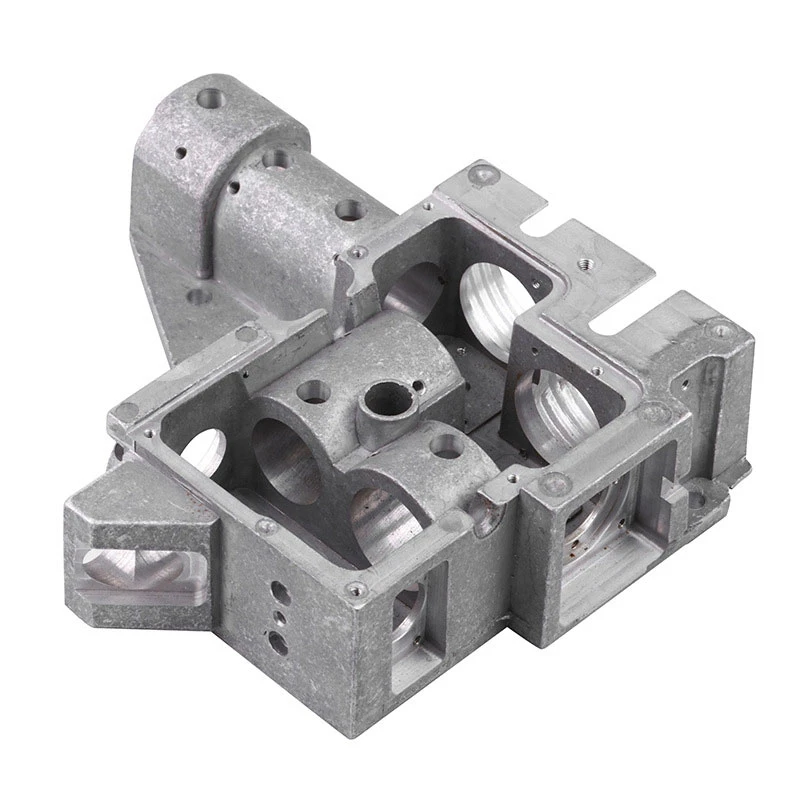

Casting 6 represents an advancement that integrates improved materials and techniques, allowing for more intricate designs and faster production times. The innovation stems from a combination of technological advances in materials science and precision engineering, resulting in enhanced durability and accuracy in the final castings.

What Sets Casting 6 Apart?

One of the defining features of casting 6 is its utilization of advanced alloys that provide superior mechanical properties. These materials are characterized by high strength-to-weight ratios, excellent corrosion resistance, and enhanced thermal stability. When combined with innovative casting techniques, these alloys have significantly reduced the production of waste and increased the yield of usable products.

Another key aspect of casting 6 is its incorporation of computerized numerical control (CNC) technology. CNC allows for precise manipulation of molds, enabling the production of complex shapes that were once deemed impossible. This technological integration greatly enhances the efficiency of the casting process, allowing manufacturers to meet the increasing demand for customized products in various industries.

casting6

Applications of Casting 6

The applications of casting 6 are far-reaching, impacting many sectors including aerospace, automotive, art, and construction. In aerospace, for example, the lightweight yet strong components produced through casting 6 can lead to significant fuel savings and improved overall performance of aircraft. In the automotive sector, the method is used for producing intricate parts that enhance vehicle efficiency and safety.

The artistic domain has also seen the influence of casting 6. Artists and sculptors leverage these advanced techniques to explore new forms and expressions in their work. The ability to easily replicate intricate designs allows them to push creative boundaries, creating pieces that are not only visually stunning but also structurally sound.

The Future of Casting 6

While casting 6 has already made significant strides, the future holds even greater promise. Researchers are continually exploring the potential of bio-based materials and recycling methods to further minimize the environmental impact of casting processes. The focus on sustainable manufacturing practices will likely reshape the landscape of casting, paving the way for more eco-friendly solutions.

Moreover, as industries increasingly embrace automation and artificial intelligence, the integration of these technologies within casting processes could lead to unprecedented efficiency and innovation. The ability to simulate casting processes through digital modeling will allow for troubleshooting and optimization before physical production, saving time and reducing costs.

Conclusion

Casting 6 stands as a testament to the marriage of art and science in the field of manufacturing. Its advanced materials and technologies have redefined the possibilities of casting, offering improved efficiency and enhanced artistry. As we move forward, the ongoing innovations within casting will not only shape the future of production but also open new avenues for creativity and sustainability. This evolution reflects the relentless drive of human ingenuity to create and innovate, ensuring that casting will continue to play a vital role in our industrial and artistic landscapes for years to come.

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Engineering&Fluid ControlNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025