febr . 20, 2025 10:09

Back to list

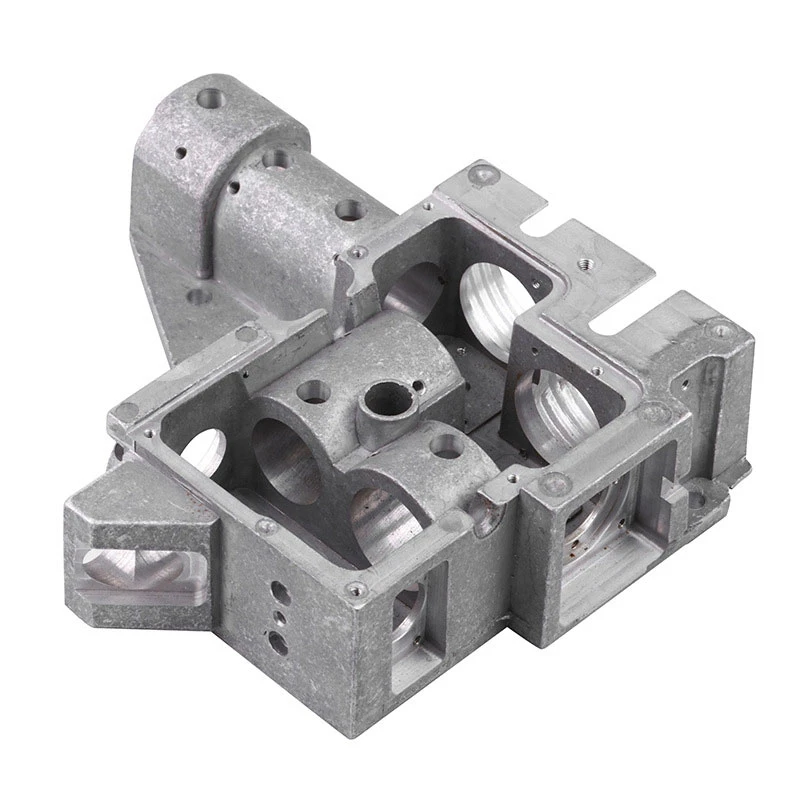

Oem Stamping Parts

Unlocking the Secrets of Stamp Parts A Comprehensive Guide

The expertise required to produce stamp parts extends beyond technical skill. It demands an in-depth understanding of metallurgy, engineering principles, and application-specific knowledge. This specialization ensures that manufacturers can anticipate and circumvent potential issues, integrating seamlessly with other components to enhance overall system performance. In the realm of authority and credibility, leading manufacturers of stamp parts have established themselves as industry pioneers through continuous innovation and adherence to the highest standards. These companies invest significantly in research and development, fostering advancements in materials science and manufacturing techniques. Their commitment to excellence is reflected in certifications such as ISO and AS9100, signifying adherence to international standards in quality management. Trust, an indispensable component of the manufacturing industry, is reinforced through rigorous testing and quality assurance. Each stamp part undergoes a battery of tests to verify its endurance, precision, and overall quality. This comprehensive approach to quality control ensures that clients receive products that consistently meet or exceed their expectations, fostering trust and long-term partnerships. For businesses looking to leverage the full potential of stamp parts, collaboration with esteemed manufacturers provides invaluable benefits. Access to their expertise can streamline production processes, offering tailored solutions that align with unique operational requirements. This partnership not only enhances the quality of the final product but also contributes to sustainable organizational growth. Overall, stamp parts serve as integral components in a vast array of industries. Their significance is underscored by their impact on the efficiency and durability of countless products. By delving into the specialized world of stamp parts, businesses can unlock new levels of innovation and performance, driving both quality and success in today’s competitive market.

The expertise required to produce stamp parts extends beyond technical skill. It demands an in-depth understanding of metallurgy, engineering principles, and application-specific knowledge. This specialization ensures that manufacturers can anticipate and circumvent potential issues, integrating seamlessly with other components to enhance overall system performance. In the realm of authority and credibility, leading manufacturers of stamp parts have established themselves as industry pioneers through continuous innovation and adherence to the highest standards. These companies invest significantly in research and development, fostering advancements in materials science and manufacturing techniques. Their commitment to excellence is reflected in certifications such as ISO and AS9100, signifying adherence to international standards in quality management. Trust, an indispensable component of the manufacturing industry, is reinforced through rigorous testing and quality assurance. Each stamp part undergoes a battery of tests to verify its endurance, precision, and overall quality. This comprehensive approach to quality control ensures that clients receive products that consistently meet or exceed their expectations, fostering trust and long-term partnerships. For businesses looking to leverage the full potential of stamp parts, collaboration with esteemed manufacturers provides invaluable benefits. Access to their expertise can streamline production processes, offering tailored solutions that align with unique operational requirements. This partnership not only enhances the quality of the final product but also contributes to sustainable organizational growth. Overall, stamp parts serve as integral components in a vast array of industries. Their significance is underscored by their impact on the efficiency and durability of countless products. By delving into the specialized world of stamp parts, businesses can unlock new levels of innovation and performance, driving both quality and success in today’s competitive market.

Latest news

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Engineering&Fluid ControlNewsJul.30,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.30,2025

PRODUCTS CATEGORIES