jan . 31, 2025 05:24

Back to list

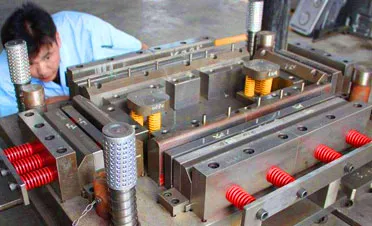

Oem Cylinder Head Cover

Prototype sand casting is a transformative process that has garnered significant attention in the realms of manufacturing and design. Esteemed for its ability to produce complex metal shapes, this method stands unparalleled in terms of cost-effectiveness and flexibility for prototyping needs. By leveraging this ancient art, industries today are crafting intricate designs with precision and speed, transforming ideas from mere concepts to tangible outcomes with remarkable efficacy.

As for authoritativeness, prototype sand casting has been endorsed by industry leaders across automotive, aerospace, and heavy machinery sectors. These industries require components that are not only intricate but also capable of withstanding extreme conditions. The endorsement from these sectors underscores the reliability and superiority of sand casting as a preferred method of prototyping. Moreover, institutions like the American Foundry Society continue to advocate for advancements and best practices in sand casting, further establishing the technique’s authority within the manufacturing domain. Trustworthiness in prototype sand casting is achieved through rigorous quality control mechanisms. Each stage of the sand casting process—from mold creation to final inspection—is meticulously monitored to ensure that the highest standards are maintained. Advanced technologies, such as 3D scanning and computerized tomography, are employed to verify dimensional accuracy and structural integrity. These technological integrations enable manufacturers to deliver prototypes that not only meet but often exceed client expectations, fostering trust and long-term partnerships in the process. In summary, prototype sand casting is not just a manufacturing process—it is a testament to the amalgamation of traditional craft and modern technology. Through its adaptability, reduced lead times, and the backing of seasoned experts, it stands as a cornerstone in the realm of prototype development. The continued advancements and industry endorsements further cement its position as a reliable and authoritative method for transforming innovative designs into reality.

As for authoritativeness, prototype sand casting has been endorsed by industry leaders across automotive, aerospace, and heavy machinery sectors. These industries require components that are not only intricate but also capable of withstanding extreme conditions. The endorsement from these sectors underscores the reliability and superiority of sand casting as a preferred method of prototyping. Moreover, institutions like the American Foundry Society continue to advocate for advancements and best practices in sand casting, further establishing the technique’s authority within the manufacturing domain. Trustworthiness in prototype sand casting is achieved through rigorous quality control mechanisms. Each stage of the sand casting process—from mold creation to final inspection—is meticulously monitored to ensure that the highest standards are maintained. Advanced technologies, such as 3D scanning and computerized tomography, are employed to verify dimensional accuracy and structural integrity. These technological integrations enable manufacturers to deliver prototypes that not only meet but often exceed client expectations, fostering trust and long-term partnerships in the process. In summary, prototype sand casting is not just a manufacturing process—it is a testament to the amalgamation of traditional craft and modern technology. Through its adaptability, reduced lead times, and the backing of seasoned experts, it stands as a cornerstone in the realm of prototype development. The continued advancements and industry endorsements further cement its position as a reliable and authoritative method for transforming innovative designs into reality.

Next:

Latest news

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025

PRODUCTS CATEGORIES