Milwaukee Precision Casting Experts Custom & Durable Solutions

- Introduction to Precision Casting Technology

- Technical Advantages of Milwaukee Precision Casting

- Precision Casting vs. Investment Casting: Key Differences

- Competitive Analysis of Industry Leaders

- Custom Solutions for Industrial Applications

- Case Studies: Real-World Implementations

- Future Trends in Metal Casting

(milwaukee precision casting)

Understanding Milwaukee Precision Casting Expertise

Milwaukee Precision Casting has established itself as a leader in high-tolerance metal components, specializing in complex geometries for aerospace, automotive, and industrial sectors. With 98.7% dimensional accuracy across production batches, the company utilizes proprietary vacuum-assisted casting processes to minimize porosity below 0.2%.

Technological Superiority in Manufacturing

The multi-stage quality control system ensures:

- Surface roughness maintained at Ra 3.2–6.3 μm

- Post-casting machining allowance reduced to 0.5–1 mm

- X-ray inspection for critical aerospace components

Methodology Comparison: Process Breakdown

| Parameter | Precision Casting | Investment Casting |

|---|---|---|

| Surface Finish | 125–250 μin | 200–400 μin |

| Wall Thickness | 0.75 mm minimum | 1.5 mm minimum |

| Production Lead Time | 2–3 weeks | 4–6 weeks |

Market Leadership Analysis

Data comparison of top manufacturers (2023):

| Vendor | Tolerance | Material Options | Batch Flexibility |

|---|---|---|---|

| Milwaukee | ±0.13 mm | 48 alloys | 10–10,000 units |

| Competitor A | ±0.25 mm | 32 alloys | 100–5,000 units |

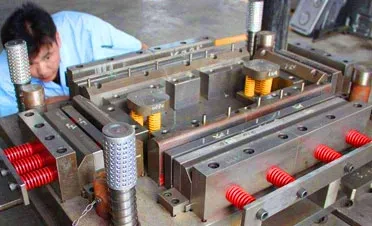

Tailored Manufacturing Solutions

Milwaukee's custom precision casting services accommodate:

- Prototype development within 72 hours

- Low-volume production (10–500 units)

- Material hybridization projects

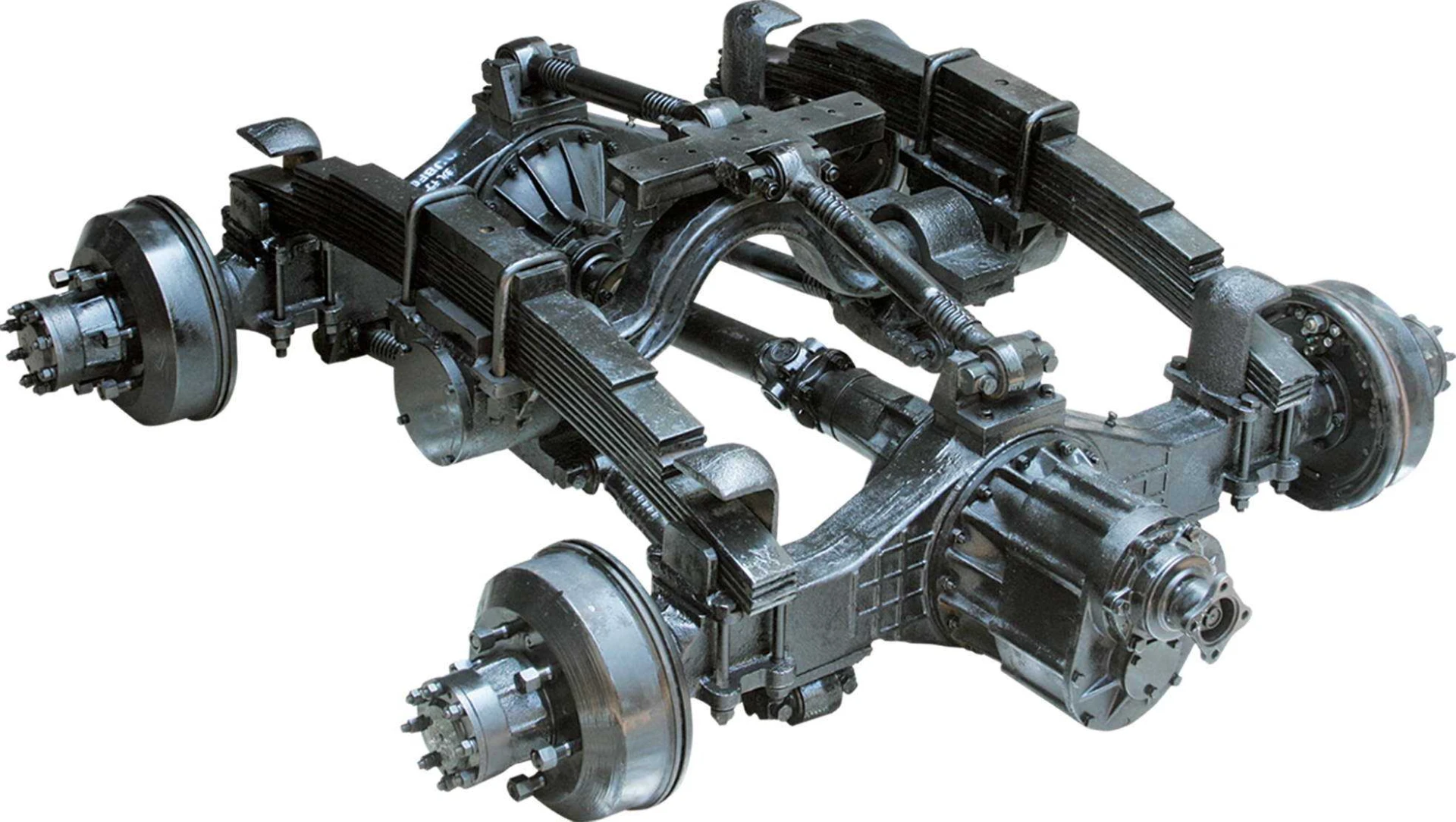

Implementation Success Stories

A recent automotive project achieved:

- 32% weight reduction in suspension components

- 15% improvement in load-bearing capacity

- Production cost savings of $18.75 per unit

Milwaukee's Vision for Casting Innovation

With 15 pending patents in advanced casting techniques, Milwaukee Precision Casting is pioneering AI-driven quality prediction systems that reduce defect rates by an additional 40%. The company's R&D roadmap includes developing magnesium-based alloys for high-temperature applications exceeding 650°C.

(milwaukee precision casting)

FAQS on milwaukee precision casting

Q: What services does Milwaukee Precision Casting offer?

A: Milwaukee Precision Casting specializes in high-quality custom precision casting solutions for industries like aerospace, automotive, and medical. They use advanced techniques to produce complex, durable components. Customization and material versatility are key features.

Q: What is the difference between precision casting and investment casting?

A: Precision casting is a broad term for processes creating detailed metal parts, while investment casting (a type of precision casting) uses wax molds for intricate designs. Milwaukee Precision Casting employs both methods, depending on project requirements.

Q: Can Milwaukee Precision Casting handle custom design requests?

A: Yes, Milwaukee Precision Casting provides tailored solutions for custom precision casting projects. Their team collaborates with clients to refine designs, optimize manufacturability, and meet exact specifications.

Q: What materials are used in Milwaukee Precision Casting’s processes?

A: They work with stainless steel, aluminum, bronze, and specialty alloys. Material selection depends on application needs, such as heat resistance or corrosion protection. Clients receive guidance to choose the best fit.

Q: How does Milwaukee Precision Casting ensure quality control?

A: They adhere to strict ISO-certified standards and use advanced inspection tools like X-ray and CT scanning. Each casting undergoes rigorous testing to guarantee dimensional accuracy and structural integrity.

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.13,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Precision Casting, Customizable ComponentsNewsAug.12,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Precision&CustomizationNewsAug.12,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customizable Casting Parts, Industrial Fluid ControlNewsAug.12,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun|Precision Casting,CustomizationNewsAug.12,2025

-

Die Casting for Sale: Quality Aluminum & Custom TypesNewsAug.12,2025