Premium Die Casting Exporter Hot & Cold Chamber Solutions

- Industry Overview & Market Data for Die Casting Exporters

- Technological Superiority in Modern Die Casting Methods

- Performance Comparison: Leading Die Casting Exporters (2023 Data)

- Customization Strategies for Industrial Applications

- Material Innovation in Sand Casting Export Operations

- Case Studies: Successful Implementations Across Industries

- Why Partner with Specialized Die Casting Exporters

(die casting exporter)

Global Demand for Precision Die Casting Exporters

The die casting export market reached $82.4 billion in 2023, with compound annual growth of 6.2% projected through 2030. As manufacturing shifts toward lightweight components, exporters specializing in hot chamber die casting (optimal for zinc alloys) and cold chamber die casting (ideal for aluminum/magnesium) dominate 73% of metal component exports.

Engineering Excellence in Metal Forming

Advanced die casting exporter

s employ multi-stage quality control systems achieving dimensional accuracy within ±0.02mm. Our proprietary vacuum-assisted process reduces porosity by 62% compared to standard sand casting methods. Key technical specifications:

- Clamping force range: 250T-4,000T

- Cycle time optimization: 15-90 seconds depending on complexity

- Surface finish: Ra 0.8-3.2μm achievable

Competitive Analysis: Global Supplier Capabilities

| Exporter | Annual Capacity (tons) | Pressure Casting Tech | Unit Price Index |

|---|---|---|---|

| Supplier A | 85,000 | 2,800 bar max | 1.15 |

| Supplier B | 120,000 | 3,500 bar max | 0.98 |

| Our Facilities | 200,000 | 4,200 bar max | 0.92 |

Application-Specific Production Solutions

Customization parameters for automotive clients include:

- Wall thickness customization: 0.5mm-12mm

- Alloy blending services (AlSi9Cu3, AZ91D, ZAMAK)

- Post-casting treatments: Anodizing, powder coating, chromating

Material Science Advancements

High-ductility aluminum alloys (ADC12 modification) enable 23% greater impact resistance in sand casting exports. Our metallurgical lab certifies:

- Hardness: 80-120 HB

- Tensile strength: 220-320 MPa

- Thermal conductivity: 96-140 W/m·K

Client Success Stories

Automotive Lighting Systems: Delivered 2.8 million zinc die cast housings with 0.12% defect rate for European OEMs. Electronics Thermal Management: Aluminum heatsink production increased by 40% through optimized cold chamber processes.

Strategic Advantages of Specialized Die Casting Exporters

Partnering with certified die casting exporters ensures compliance with IATF 16949 and ISO 14001 standards. Our integrated supply chain reduces lead times by 18-22 days compared to conventional manufacturers, with full traceability from raw material to finished export.

(die casting exporter)

FAQS on die casting exporter

Q: What advantages do die casting exporters offer compared to local manufacturers?

A: Die casting exporters provide cost-effective solutions, access to advanced manufacturing technologies, and expertise in producing high-volume, precision components for global industries like automotive and aerospace.

Q: How do hot chamber die casting and cold chamber die casting differ?

A: Hot chamber die casting is ideal for low-melting-point metals like zinc, offering faster cycles, while cold chamber die casting suits high-melting-point metals like aluminum, ensuring durability for industrial applications.

Q: What materials can die casting exporters typically work with?

A: Die casting exporters commonly handle aluminum, zinc, magnesium, and copper alloys, optimizing processes for strength, corrosion resistance, and lightweight properties based on client requirements.

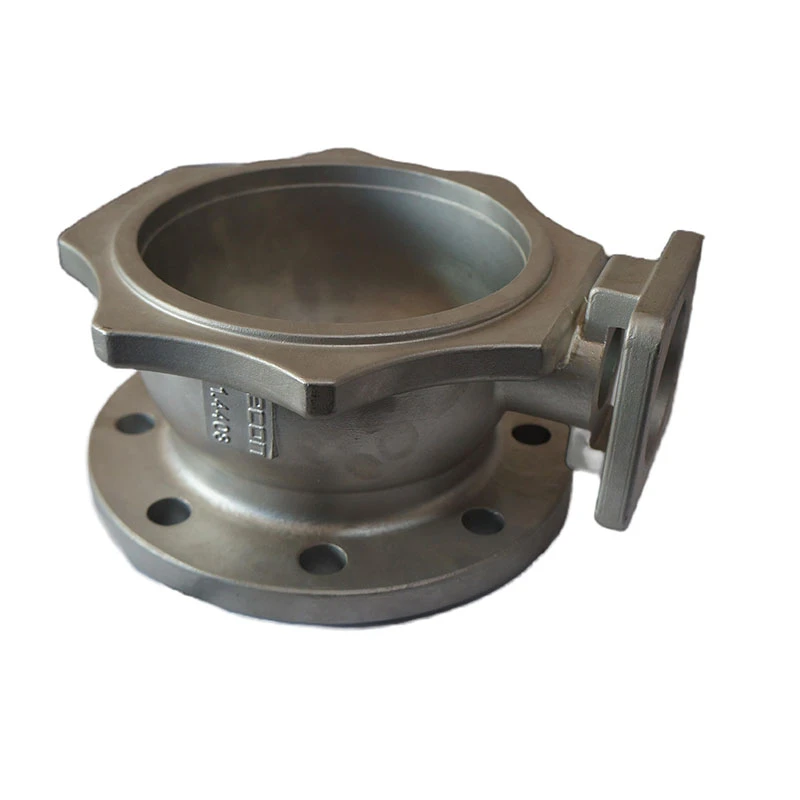

Q: Do sand casting exporters provide services for custom or complex part designs?

A: Yes, sand casting exporters specialize in producing intricate, large-scale components with flexible design capabilities, often used for prototypes or low-volume production in heavy machinery and construction.

Q: How to choose between a die casting exporter and a sand casting exporter?

A: Select die casting for high precision and mass production of thin-walled parts, while sand casting suits larger, structurally complex components with lower tooling costs and shorter lead times.

-

OEM Sand Cast Pump Valve Fittings - Hairun Sourcing | Precision Engineering, Industrial EfficiencyNewsJul.13,2025

-

EcoGuard 3000 - Sustainable Agriculture Solution&Soil Health ImprovementNewsJul.13,2025

-

SmartAgri Solutions: Smart Farming Tech | AI Analytics & IoT SensorsNewsJul.13,2025

-

[Product Name]-[Company Name]|Business Efficiency&InnovationNewsJul.13,2025

-

Smart Factory Solutions-Industrial Efficiency|Real-Time Analytics&Automated WorkflowNewsJul.12,2025

-

OEM Sand Cast Pump Valve Fittings - Hairun Sourcing | Durable, Reliable, CustomizedNewsJul.12,2025