Choosing the right foundry sand: the key to improving metal casting quality

When it comes to sand casting, the quality of the casting sand plays a crucial role in the production of high-quality metal components. Whether you are a seasoned manufacturer or just starting your casting journey, selecting the right casting sand for sale is essential for achieving superior results. A wide variety of sand options are available in the market, each designed for different purposes and industries. From basic sand casting to more advanced processes like aluminum casting, the right type of sand can significantly impact the precision, surface finish, and overall quality of the casted parts.

Choosing casting sand for sale requires consideration of several factors. First, you need to evaluate the type of metal that will be cast. For example, if you are working with aluminum, a specific sand mixture may be necessary for optimal results. The sand must have the right balance of permeability, strength, and ability to hold its shape during the casting process. Additionally, the grain size and composition of the sand are important factors that influence the final product's detail and surface finish.

Working with trusted suppliers that offer high-quality casting sand for sale ensures that you receive reliable materials that meet the standards required for your casting processes. Many sand casting manufacturers offer tailored sand products that meet industry-specific needs, whether you are casting large industrial parts or small, intricate components. Always make sure to buy from reputable suppliers who provide consistent quality and customer service.

Advantages of Working with Sand Casting Manufacturers

Collaborating with reputable sand casting manufacturers can offer a variety of benefits to your business. Sand casting is one of the oldest and most widely used methods in the metalworking industry, and it continues to be popular due to its cost-effectiveness and versatility. Experienced manufacturers can guide you through the selection of the right casting sand for sale, ensuring that the materials you purchase are perfectly suited for your needs.

Sand casting manufacturers offer a range of casting sand options for different applications, from basic green sand to more specialized mixtures. They help ensure that you get the right material for your specific needs, whether you are casting aluminum, steel, or other metals. These manufacturers also have the capability to provide you with custom sand mixtures that meet your specific requirements.

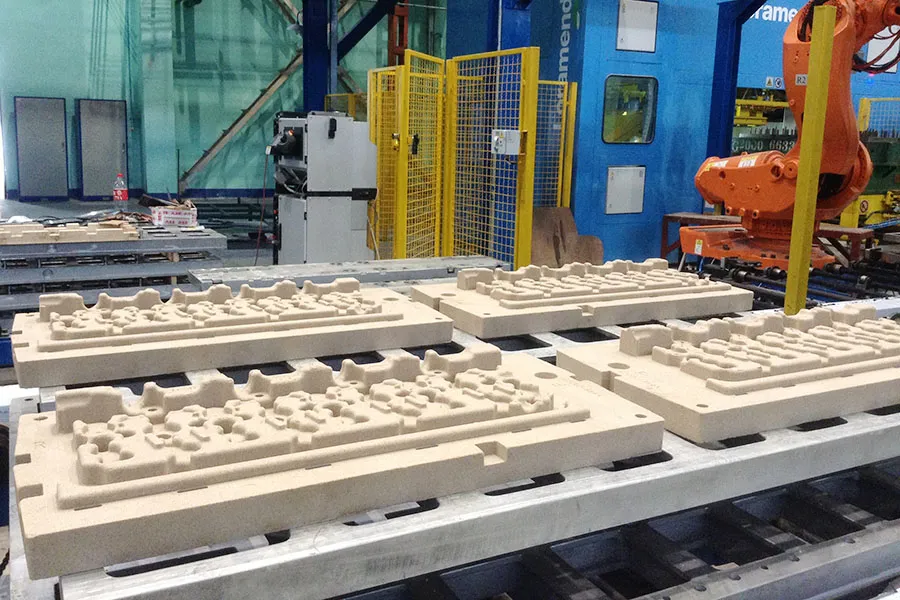

Additionally, working with experienced sand casting manufacturers can lead to better production results. These companies have the expertise and state-of-the-art equipment necessary for producing high-quality molds and castings. They also offer advanced quality control systems, ensuring that every product they create meets the highest standards of dimensional accuracy and surface finish.

Whether you are casting large, complex components or smaller, more intricate parts, sand casting manufacturers have the experience and resources to help you achieve optimal results, increasing efficiency and reducing the potential for defects in the casting process.

Why You Should Buy Green Sand for Casting

When looking for sand for casting, one of the most popular options is green sand. Green sand for casting refers to a mixture of sand, clay, water, and sometimes other additives, which is widely used in the sand casting process. It is called "green" because the mixture is not yet fully dried or hardened when used in the mold-making process, making it highly versatile and reusable.

One of the main reasons businesses choose to buy green sand for casting is its cost-effectiveness. Green sand is inexpensive compared to other casting sands and can be reused multiple times, making it an economical choice for high-volume production. Additionally, green sand is known for its excellent moldability, allowing manufacturers to create intricate designs with precise detail. This is particularly useful for industries that require high-precision components, such as automotive, aerospace, and industrial machinery.

Green sand also provides excellent heat resistance, making it ideal for casting materials like sand casting aluminum. The mixture of sand and clay helps to absorb and dissipate the heat generated during the pouring of molten metal, which results in smoother and more accurate castings.

Another benefit of buying green sand for casting is its environmental impact. Since it can be recycled and reused, green sand minimizes waste and reduces the need for constant procurement of fresh materials. This eco-friendly approach to casting helps businesses lower their overall environmental footprint.

The Best Practices for Sand Casting Aluminum

Sand casting aluminum is a common method used in industries that require strong, durable, and lightweight components. The aluminum casting process involves pouring molten aluminum into a mold made from sand, where it solidifies and takes the shape of the mold. Using the right sand mixture is crucial to achieving high-quality castings that meet the desired specifications.

When sand casting aluminum, the type of sand used plays a key role in the final product's quality. Green sand is often the preferred choice for aluminum casting, as it can withstand the high temperatures generated by molten metal and offers excellent detail reproduction. However, some manufacturers may also choose other types of sands, such as resin-bonded sands or shell sands, depending on the complexity of the part being cast.

To achieve the best results in sand casting aluminum, it's important to maintain proper sand moisture content and ensure the mold is compacted correctly. Compaction helps to minimize air pockets and ensures the mold retains its shape during pouring. The surface of the mold should also be treated with coatings that help improve the finish and prevent defects like casting porosity.

Furthermore, the pouring temperature of the aluminum is a critical factor. Aluminum must be melted at a high enough temperature to ensure smooth flow into the mold, but not so high that it causes defects like oxidation or excessive expansion. Proper temperature control is essential for ensuring a high-quality sand casting aluminum product.

Why Choose the Right Supplier for Casting Sand for Sale

Choosing the right supplier for casting sand for sale is an essential step in ensuring the success of your casting operations. The supplier you work with can have a significant impact on the quality of the materials you use, and ultimately, the quality of your final products. A reliable supplier can provide you with high-quality casting sand for sale that meets the specific requirements of your manufacturing process.

When selecting a supplier, it's important to consider factors such as the consistency and purity of the sand, as well as the supplier's reputation for reliability and customer service. Suppliers who offer custom formulations and high-quality sand mixtures can help you meet the exact specifications required for your sand casting aluminum or other metal casting projects.

In addition, working with a reputable supplier who offers guidance and support throughout the process can help prevent costly mistakes. They can assist you in selecting the best sand mixture for your casting needs and provide advice on mold preparation, sand conditioning, and recycling techniques.

A reliable supplier will also ensure that the casting sand for sale is produced under strict quality control standards, which ensures uniformity and reduces the risk of defects during the casting process. Ultimately, working with a trusted supplier helps you save time, reduce costs, and achieve higher-quality finished products.

Sand Casting FAQs

What is casting sand for sale and why is it important?

Casting sand for sale refers to the sand used in the process of casting metals, particularly in the creation of molds for metal pouring. The quality and type of casting sand are important because they affect the mold's ability to withstand heat, produce fine details, and ensure the integrity of the casted parts.

How can I choose the best sand casting manufacturers for my business?

To choose the best sand casting manufacturers, evaluate their experience, production capabilities, quality control measures, and customer reviews. Ensure they provide the right sand materials and casting techniques suitable for your metal casting needs, whether it's sand casting aluminum or other metals.

What are the advantages of buying green sand for casting?

Buying green sand for casting is beneficial because it is cost-effective, reusable, and provides excellent moldability. Green sand is ideal for a wide range of casting applications and helps manufacturers achieve high-precision components while minimizing waste.

What makes sand casting aluminum popular in industries?

Sand casting aluminum is popular due to its versatility, cost-effectiveness, and ability to produce lightweight, durable parts. Aluminum casting in sand molds offers good heat resistance, high precision, and is widely used in automotive, aerospace, and industrial applications.

How do I ensure the quality of casting sand for sale?

Ensure the quality of casting sand for sale by working with trusted suppliers who provide consistent, high-quality sand products. Look for suppliers who adhere to strict quality control processes and offer custom sand formulations tailored to your specific needs.

-

Why Choose OEM Spark Plugs for Optimal Engine PerformanceNewsJul.16,2025

-

Unlock the Power of Die CastingNewsJul.16,2025

-

The Power of Sand Casting for Your Manufacturing NeedsNewsJul.16,2025

-

The Excellence of Precision CastingsNewsJul.16,2025

-

Maximize Efficiency with High-Quality Stamping PartsNewsJul.16,2025

-

Enhance Your Manufacturing with Aluminium Die CastingsNewsJul.16,2025