carbon steel investment precision casting automobile spare parts

Exploring Carbon Steel Investment Precision Casting for Automobile Spare Parts

The automotive industry is an intricate ecosystem where every component must meet stringent standards for safety, performance, and durability. In this context, carbon steel investment precision casting has emerged as a crucial manufacturing technique for producing high-quality automobile spare parts. This method allows for the creation of complex geometries with tight tolerances, ensuring that each component functions optimally in a vehicle's intricate assembly.

What is Carbon Steel Investment Precision Casting?

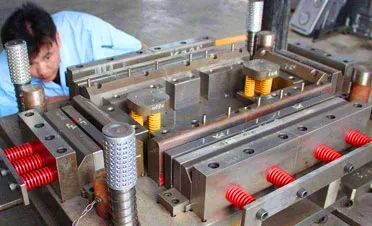

Investment casting, often referred to as lost-wax casting, is a manufacturing process that involves creating a wax pattern of the desired part, coating it with a ceramic shell, and then melting away the wax to produce a mold. When this mold is filled with molten carbon steel, it captures the precise details of the original pattern. This technique is highly valued in the production of automobile spare parts for several reasons, including enhanced accuracy, reduced waste, and the ability to create intricate designs.

Carbon steel, an alloy of iron and carbon, is favored in the automotive sector for its balance of strength, ductility, and wear resistance. The addition of carbon increases the steel's hardness, making it suitable for various automotive applications, including gears, crankshafts, and various connection components. The precision casting process ensures that every piece retains these beneficial properties while adhering to the specified dimensions and tolerances.

Advantages of Carbon Steel Investment Casting in the Automotive Sector

1. High Precision and Detail One of the primary advantages of investment casting is its ability to create parts with complex shapes and intricate details. This is crucial for automotive spare parts that must fit seamlessly with other components, ensuring optimal vehicle performance.

2. Material Efficiency Traditional manufacturing methods often result in significant material waste, particularly when machining is involved. Investment casting minimizes this waste as the molten metal fills the mold cavities entirely, leading to a near-net-shape production process. This efficiency not only conserves resources but also reduces costs.

carbon steel investment precision casting automobile spare parts

3. Versatility in Design The flexibility offered by investment casting allows manufacturers to adapt designs quickly. This adaptability is essential in the automotive industry, where design changes are frequent in response to innovation, consumer preferences, or regulatory requirements.

4. Excellent Surface Finish Parts produced via investment casting can achieve a superb surface finish. This precludes the need for extensive finishing processes, saving both time and money, which are critical factors in the highly competitive automotive market.

5. Performance Under Extreme Conditions Carbon steel parts can withstand high stress and varying temperatures, which are prevalent in automotive environments. This durability is vital for components that play critical roles in vehicle safety and functionality.

Future Trends and Innovations

As the automotive industry continues to evolve, particularly with the rise in electric vehicles (EVs) and growing environmental regulations, the demand for efficient and sustainable manufacturing processes is increasing. Investment casting, with its reduced material waste and energy efficiency, is well-positioned to meet these evolving needs. Furthermore, advancements in materials science and casting technology could lead to even finer control over mechanical properties, enhancing the performance of carbon steel components further.

The growing emphasis on lightweight materials also suggests that, while carbon steel remains vital, new alloys and composite materials may start to complement traditional steel components. Investment casting can play a pivotal role in this transition, facilitating the production of hybrid parts that combine the advantages of various materials.

Conclusion

In summary, carbon steel investment precision casting has proven to be a vital technique in the production of automobile spare parts, offering numerous advantages in terms of precision, efficiency, and versatility. As the automotive landscape transforms, embracing new technologies and sustainability practices, investment casting is likely to remain a cornerstone of automotive manufacturing. Its ability to meet high demands will ensure that it continues to contribute to the advancement of the industry for years to come.

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun | Precision Engineering, CustomizableNewsJul.30,2025