machining supplier

The Importance of Choosing the Right Machining Supplier

In today's fast-paced manufacturing environment, the choice of a machining supplier plays a critical role in the success of production operations. Machining encompasses a variety of processes such as milling, turning, drilling, and grinding, which are essential for creating precision components across industries such as automotive, aerospace, electronics, and medical devices. Consequently, selecting the right supplier can directly impact product quality, production efficiency, and overall profitability.

Quality Assurance and Precision

One of the foremost factors to consider when selecting a machining supplier is their commitment to quality assurance. Precision machining requires not only advanced machinery but also skilled operators and stringent quality control measures. It is essential to verify that the supplier adheres to recognized quality standards such as ISO 9001 or AS9100, particularly for industries with stringent regulatory requirements. This commitment to quality ensures that components meet specifications and reduces the risk of defects, thereby minimizing costly rework and delays.

Technological Capabilities

As technology continues to evolve, so do the capabilities of machining suppliers. Having access to the latest machining technologies can significantly enhance the production process. Suppliers equipped with advanced CNC (Computer Numerical Control) machines, 3D printing capabilities, and automated systems can provide higher levels of precision and efficiency. These technologies also enable suppliers to handle complex geometries and produce intricate designs that might be challenging with traditional machining methods. When evaluating a supplier, it is important to assess their technological capabilities and how they align with the specific needs of your project.

Lead Times and Flexibility

In the competitive arena of manufacturing, time is often of the essence. Choosing a machining supplier that can meet tight lead times and adapt to changing project requirements is crucial. A reliable supplier should offer flexibility, whether it's adjusting quantities, modifying designs, or accommodating rush orders. Establishing a good communication channel with the supplier can facilitate better planning and help avoid unnecessary delays, ensuring that production timelines are met.

machining supplier

Cost Considerations

While quality and technological capabilities are paramount, cost remains a critical factor in the decision-making process. It is essential to obtain quotes from multiple suppliers to understand the market rate. However, the cheapest option is not always the best. It is vital to consider the overall value offered by a supplier, which includes quality, reliability, customer service, and post-production support. An investment in a higher-quality supplier may yield lower overall costs in the long run through reduced scrap rates, fewer production interruptions, and enhanced product performance.

Customer Service and Support

Exceptional customer service is another integral aspect of choosing a machining supplier. Communication and support throughout the production process can prevent misunderstandings and ensure that specifications are met. A supplier that actively engages with customers, provides updates on project status, and responds promptly to inquiries demonstrates a commitment to customer satisfaction. Additionally, strong post-production support, including assistance with logistics or addressing concerns, can be a significant advantage.

Long-Term Partnership Potential

Finally, consider the potential for a long-term partnership with the machining supplier. Building a stable relationship can prove beneficial for both parties, leading to better pricing, improved service, and enhanced collaboration on future projects. A supplier that understands your business context, product requirements, and quality expectations can become an indispensable partner in your manufacturing process.

In conclusion, selecting the right machining supplier is a multifaceted decision that requires careful consideration of quality, technological capabilities, lead times, costs, customer service, and potential for long-term collaboration. By prioritizing these factors, manufacturers can forge partnerships that not only meet their current needs but also pave the way for innovation and success in an ever-evolving industry landscape.

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

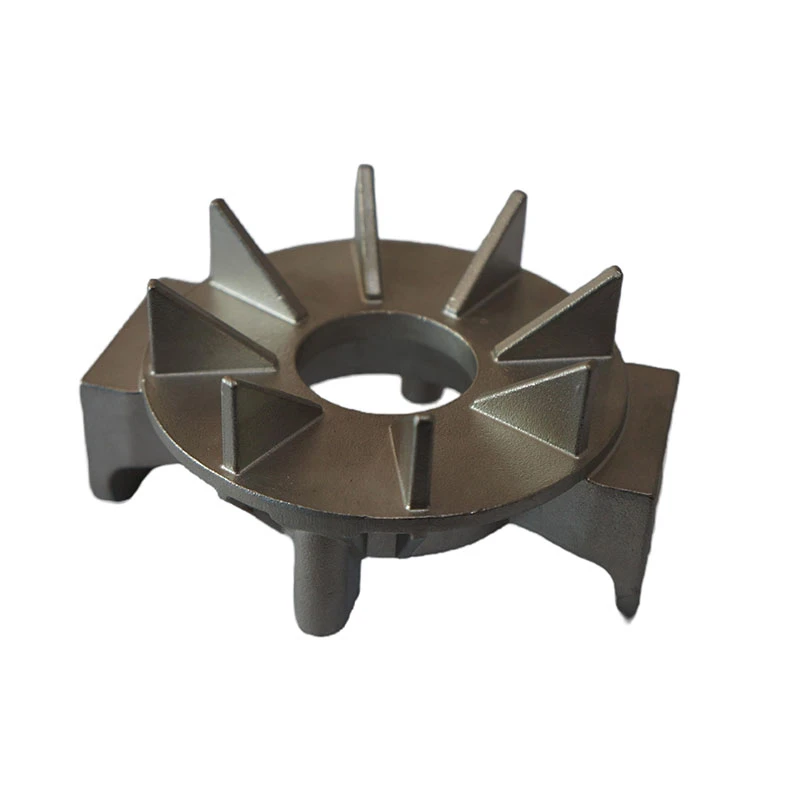

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025