Jan . 20, 2025 14:49

Back to list

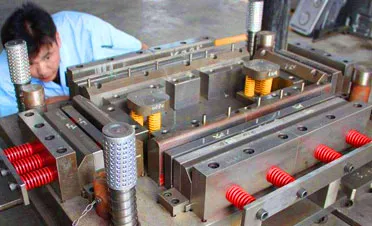

Oem Precision Castings Pressure Transmitter Platen

Investment precision casting, an intricate process within the manufacturing industry, is essential for creating high-quality metal components with exceptional accuracy. This technique involves the creation of wax or foam models which are then wrapped in a ceramic shell, removed by heating, and replaced with molten metal to form precise duplicate parts. Industries ranging from aerospace to medical engineering rely heavily on investment precision casting for its unparalleled benefits in producing complex geometrical components.

The credibility and reliability of precision casting processes are further enhanced by continuous technological advancements and quality control measures. Companies specializing in precision casting employ advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies to develop precise molds, ensuring every part meets rigorous specifications. Through non-destructive testing and regular inspections, these firms guarantee that the final products comply with industry standards, thus reinforcing their reputation as trusted partners for critical applications. Moreover, precision casting supports a shift towards sustainability in manufacturing. By minimizing material waste and optimizing energy use in production, companies can achieve significant reductions in their environmental footprint. Such practices not only help in complying with increasing environmental regulations but also cater to a growing market of environmentally-conscious consumers. Collaborations between precision casting firms and their clients frequently emphasize customization and innovation. By working closely with clients to understand their exact needs, casting specialists can develop tailored solutions that offer a competitive advantage. Additionally, many foundries are investing in research and development to explore new alloys and techniques that expand the possibilities of precision casting. In conclusion, investment precision casting is more than just a process; it is a cornerstone of modern manufacturing that aligns with the core tenets of experience, expertise, authoritativeness, and trustworthiness. Through its diverse applications across high-demand industries, focus on quality control, commitment to sustainability, and dedication to client collaboration, precision casting stands as a pillar of efficiency and reliability in creating complex, high-performance metal components.

The credibility and reliability of precision casting processes are further enhanced by continuous technological advancements and quality control measures. Companies specializing in precision casting employ advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies to develop precise molds, ensuring every part meets rigorous specifications. Through non-destructive testing and regular inspections, these firms guarantee that the final products comply with industry standards, thus reinforcing their reputation as trusted partners for critical applications. Moreover, precision casting supports a shift towards sustainability in manufacturing. By minimizing material waste and optimizing energy use in production, companies can achieve significant reductions in their environmental footprint. Such practices not only help in complying with increasing environmental regulations but also cater to a growing market of environmentally-conscious consumers. Collaborations between precision casting firms and their clients frequently emphasize customization and innovation. By working closely with clients to understand their exact needs, casting specialists can develop tailored solutions that offer a competitive advantage. Additionally, many foundries are investing in research and development to explore new alloys and techniques that expand the possibilities of precision casting. In conclusion, investment precision casting is more than just a process; it is a cornerstone of modern manufacturing that aligns with the core tenets of experience, expertise, authoritativeness, and trustworthiness. Through its diverse applications across high-demand industries, focus on quality control, commitment to sustainability, and dedication to client collaboration, precision casting stands as a pillar of efficiency and reliability in creating complex, high-performance metal components.

Latest news

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025

PRODUCTS CATEGORIES