Feb . 14, 2025 11:58

Back to list

die pro cast

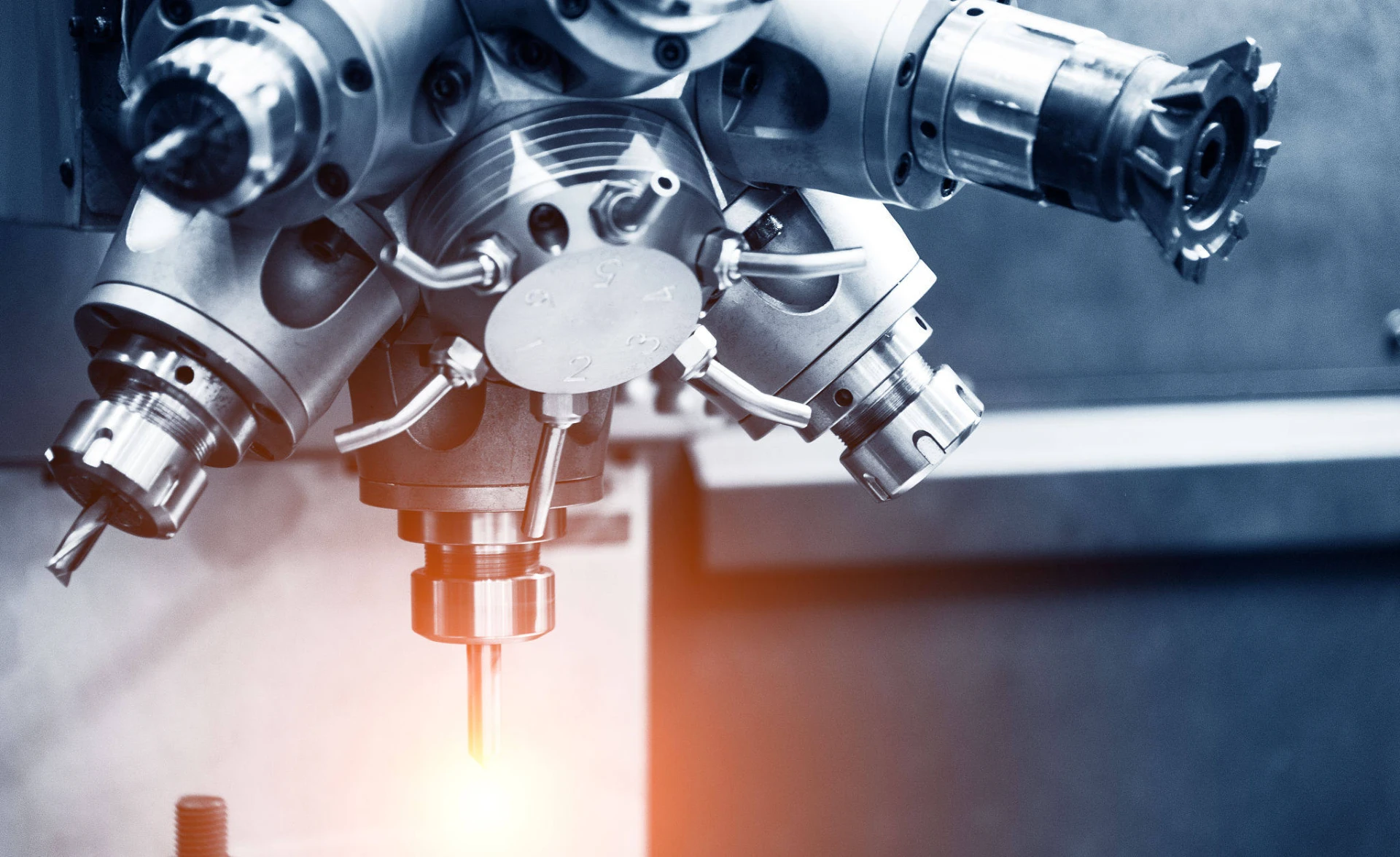

Die casting is a fascinating and intricate process often used for creating intricate metal components with a high degree of accuracy and quality. Within this context, the phrase die pro cast evokes thoughts of professional die casting services that harness advanced technologies and expert techniques to deliver superior quality products. This essay explores the fundamental aspects of die casting while illustrating the requisite expertise, real-world application of processes, and the overarching trustworthiness needed to achieve success in this field.

Trustworthiness in die casting services is underscored by stringent quality control measures. Rigorous testing and inspection protocols ensure that every cast part not only meets but exceeds the client’s expectations. This involves non-destructive testing methods such as X-ray or ultrasonic inspections that assure internal quality without altering the part. A reputable firm in die pro cast consistently practices transparency with clients, offering traceable documentation and reporting for all processes. This transparency builds a solid foundation of trust between the service provider and the client. In the product-centric world, die casting plays a pivotal role across numerous industries, including automotive, aerospace, electronics, and consumer goods. The demand for lightweight, durable components with complex geometries continues to rise, and die pro cast services can deliver these qualities cost-effectively. The intricate craftsmanship and the ability to produce high volumes with consistent quality make die casting a preferred manufacturing method for components such as engine blocks, gearboxes, and chassis components in automotive applications, or housing for electronics that require shielding and heat dissipation. Experience in die casting is not quantified merely by years in service but by the depth and breadth of project complexity managed. Companies showcasing a diverse portfolio of challenging projects command respect and recognition as they have demonstrated adaptive capabilities and problem-solving acumen. Such experience provides a competitive advantage, enabling firms to offer customized solutions that cater specifically to the nuanced needs of each sector. In conclusion, die casting, and specifically die pro cast services, represents a sophisticated convergence of science and craftsmanship. Successful practitioners draw upon a vast reservoir of technical knowledge, honed skills, and unwavering commitment to maintaining the highest standards. This crafts a narrative not only of precision and reliability but also of innovation and trustworthiness, ensuring that clients receive products that embody excellence, meet regulatory compliance, and contribute positively to their bottom line. In choosing a die casting partner, stakeholders should weigh these factors thoughtfully to unlock the full potential that professional die casting services can offer.

Trustworthiness in die casting services is underscored by stringent quality control measures. Rigorous testing and inspection protocols ensure that every cast part not only meets but exceeds the client’s expectations. This involves non-destructive testing methods such as X-ray or ultrasonic inspections that assure internal quality without altering the part. A reputable firm in die pro cast consistently practices transparency with clients, offering traceable documentation and reporting for all processes. This transparency builds a solid foundation of trust between the service provider and the client. In the product-centric world, die casting plays a pivotal role across numerous industries, including automotive, aerospace, electronics, and consumer goods. The demand for lightweight, durable components with complex geometries continues to rise, and die pro cast services can deliver these qualities cost-effectively. The intricate craftsmanship and the ability to produce high volumes with consistent quality make die casting a preferred manufacturing method for components such as engine blocks, gearboxes, and chassis components in automotive applications, or housing for electronics that require shielding and heat dissipation. Experience in die casting is not quantified merely by years in service but by the depth and breadth of project complexity managed. Companies showcasing a diverse portfolio of challenging projects command respect and recognition as they have demonstrated adaptive capabilities and problem-solving acumen. Such experience provides a competitive advantage, enabling firms to offer customized solutions that cater specifically to the nuanced needs of each sector. In conclusion, die casting, and specifically die pro cast services, represents a sophisticated convergence of science and craftsmanship. Successful practitioners draw upon a vast reservoir of technical knowledge, honed skills, and unwavering commitment to maintaining the highest standards. This crafts a narrative not only of precision and reliability but also of innovation and trustworthiness, ensuring that clients receive products that embody excellence, meet regulatory compliance, and contribute positively to their bottom line. In choosing a die casting partner, stakeholders should weigh these factors thoughtfully to unlock the full potential that professional die casting services can offer.

Prev:

Next:

Latest news

-

Precision Machining & Manufacturing | Aerospace ExpertsNewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Precision, Quality, CustomizationNewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun|Precision Customization&Reliable Fluid ControlNewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.06,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery|Precision Fluid Control, CustomizableNewsAug.05,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Precision Customization, Quality AssuranceNewsAug.05,2025

PRODUCTS CATEGORIES