Exploring the Importance of Castings in Valve Manufacturing and Performance

Castings and Valves A Comprehensive Overview

The casting process has long been a cornerstone in manufacturing, particularly for components in the valve industry. Valves, which are essential in regulating, directing, or controlling fluid flow, demand precision, durability, and reliability. From the aerospace sector to oil and gas applications, the choice of material and method for valve manufacturing can significantly impact performance. This article delves into the significance of castings in valve production, the various casting techniques, and the benefits of utilizing castings in creating robust and efficient valves.

The Role of Castings in Valve Manufacturing

Castings are created by pouring molten metal into a mold where it solidifies into a specific shape. This method is particularly advantageous for valve manufacturing due to its ability to produce complex geometries that would be difficult or impossible to achieve with other methods such as machining or forging. Valves often require intricate internal structures for functionality, including ports, seats, and seals. Casting allows for these complex designs while minimizing waste material and production time.

Common Casting Techniques Used in Valve Production

1. Sand Casting This is one of the oldest and most common forms of casting, where a sand mold is formed around a pattern. The mold is then filled with molten metal. Sand casting is favored for its cost-effectiveness and the ability to create large parts. In valve production, sand casting can achieve a variety of sizes and shapes, making it ideal for custom valves needed in various applications.

2. Investment Casting Also known as lost-wax casting, this technique involves creating a wax model of the valve, coating it in a ceramic shell, and then melting away the wax to leave a mold. Investment casting is renowned for its precision and is often used for high-quality valve applications, particularly in industries where tight tolerances are critical.

3. Die Casting In this high-volume casting process, molten metal is injected under pressure into a mold cavity. Die casting is beneficial for producing small to medium-sized valves at a rapid pace and is commonly used in applications that require high dimensional accuracy and smooth surface finishes.

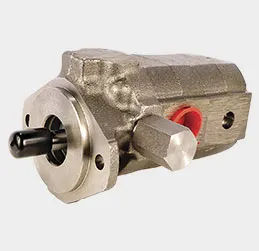

castings valve

4. Centrifugal Casting This method involves pouring molten metal into a rotating mold, which uses centrifugal force to distribute the metal evenly. Centrifugal casting is particularly suitable for producing cylindrical parts, making it an excellent choice for certain types of valve bodies.

Advantages of Using Castings for Valves

One of the primary benefits of using castings in valve production is their ability to handle a wide range of materials. Cast iron, ductile iron, stainless steel, and various alloys can all be used effectively, depending on the application's specific requirements. These materials not only provide strength but also enhance the valve's resistance to corrosion, heat, and wear.

Additionally, castings contribute to cost efficiency. The ability to produce complex shapes reduces the need for extensive machining, allowing manufacturers to offer competitive pricing without sacrificing quality. Castings also facilitate shorter lead times, which is crucial in industries requiring rapid turnaround.

Moreover, the versatility of casting processes means that manufacturers can respond to unique design specifications, making it possible for companies to create custom valves tailored to specific operational environments. This adaptability can be critical in sectors such as pharmaceuticals, food processing, and chemical manufacturing, where precise control over fluid dynamics is essential.

Conclusion

In conclusion, castings are an integral part of valve manufacturing, offering considerable benefits in terms of design flexibility, cost efficiency, and material versatility. As industries continue to evolve and demand more sophisticated and reliable components, the importance of quality casting processes in the valve sector will remain paramount. Whether through sand casting, investment casting, die casting, or centrifugal casting, manufacturers can create valves that meet the rising challenges of modern applications while ensuring performance and reliability. As technology advances, we can expect further innovations in casting techniques, further enhancing the capabilities of valve production in the years to come.

-

Precision Sheet Metal Stamping Manufacturer | Fast & ReliableNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

Custom OEM Impellers | High Efficiency & PrecisionNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Customization, Quality AssuranceNewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.01,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.31,2025