Trends in Automotive OEM Manufacturing for EVs

The shift toward electric vehicles (EVs) is reshaping automotive OEM manufacturers, driving innovation in design, production, and supply chain strategies. As global demand for EVs surges, OEM automotive suppliers are prioritizing auto precision, OEM automotive lighting, and precision tires and auto solutions to meet stringent performance and sustainability standards. This article explores how wholesale-focused OEMs are adapting to these trends, ensuring scalability and efficiency for partners worldwide.

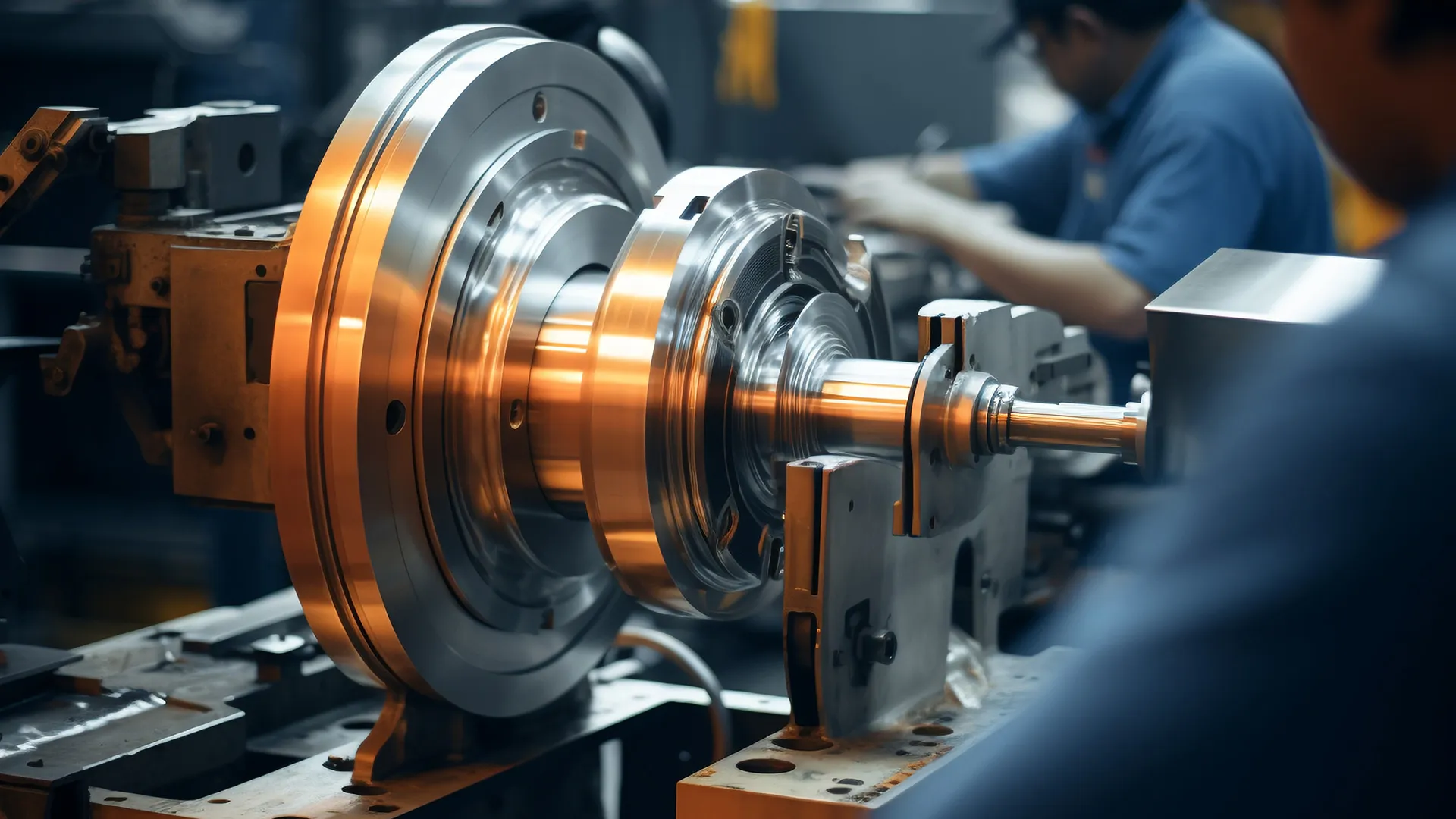

Advancements in Auto Precision for EV Component Manufacturing

The rise of EVs demands unparalleled auto precision in component production. Automotive OEM manufacturers are leveraging advanced robotics, AI-driven quality control, and micro-tolerance machining to produce lightweight, high-strength parts like battery housings and motor components. For instance, precision-engineered aluminum castings reduce vehicle weight while maintaining structural integrity, directly enhancing EV range.

Wholesale suppliers are also adopting modular manufacturing systems, allowing rapid scaling of EV-specific parts. Collaborative partnerships between OEM automotive engineers and material scientists ensure components meet thermal and electrical safety requirements. This focus on precision not only minimizes waste but also streamlines bulk production cycles, critical for cost-effective EV adoption.

OEM Automotive Lighting Innovations Driving EV Safety and Efficiency

Modern EVs rely on OEM automotive lighting systems to optimize energy use and safety. Adaptive LED matrix headlights, designed with auto precision, adjust beam patterns in real time to improve visibility without draining battery life. These systems are now standard in wholesale orders for premium EV models, reflecting their role in brand differentiation.

Wholesale-focused automotive OEM manufacturers are also integrating lighting with autonomous driving sensors. For example, LiDAR-compatible fog lights enhance object detection in adverse weather. Additionally, solar-rechargeable daytime running lights are emerging as a sustainable innovation, reducing dependency on EV batteries. Such advancements position OEM automotive lighting as a key selling point for bulk buyers prioritizing cutting-edge technology.

Precision Tires and Auto: Enhancing EV Performance Through Engineering

EVs place unique demands on precision tires and auto systems due to instant torque delivery and heavier battery loads. Wholesale tire manufacturers are developing low-rolling-resistance treads using auto precision molding techniques, which extend battery range by up to 10%. Silica-infused rubber compounds further improve grip in wet conditions, addressing safety concerns for high-torque EVs.

Collaborations between automotive OEM manufacturers and tire suppliers are also yielding "smart tires" with embedded sensors. These monitor pressure, temperature, and wear in real time, transmitting data directly to vehicle control units. For bulk procurement teams, this integration reduces maintenance costs and enhances fleet uptime—a critical factor for commercial EV operators.

Collaborative Strategies for Automotive OEM Manufacturers in the EV Era

To meet EV production targets, automotive OEM manufacturers are forging alliances with tech firms and raw material suppliers. For example, joint ventures with lithium producers ensure stable battery material supplies, while partnerships with OEM automotive lighting specialists accelerate R&D cycles.

Wholesale strategies now emphasize circular economy practices, such as remanufacturing used EV components. Auto precision tools enable OEMs to refurbish motors and inverters to "like-new" standards, reducing costs for bulk buyers. Additionally, digital twin technology allows virtual testing of precision tires and auto systems, slashing time-to-market for new EV models.

FAQs about Automotive OEM Manufacturing

How do automotive OEM manufacturers ensure quality in bulk EV component production?

OEMs employ AI-powered inspection systems and statistical process control (SPC) to maintain auto precision across high-volume batches. Multi-stage testing protocols validate durability, safety, and compliance with international standards.

What innovations in OEM automotive lighting are most impactful for EVs?

Adaptive LED systems and LiDAR-integrated lighting improve safety and energy efficiency. Solar-powered components are also gaining traction, aligning with sustainability goals for wholesale buyers.

Why are precision tires and auto systems critical for EV performance?

EVs require tires that minimize energy loss while handling increased weight and torque. Precision-engineered treads and smart sensor integration optimize range, safety, and longevity.

How are automotive OEM manufacturers addressing supply chain disruptions?

Diversified sourcing, regional production hubs, and blockchain-tracked raw materials ensure resilience. Collaborative forecasting with wholesale partners also mitigates inventory risks.

What role does auto precision play in EV battery manufacturing?

Laser welding and nanoscale coating technologies ensure battery cell consistency and thermal stability. Precision assembly lines enable scalable production of high-capacity battery packs.

-

Types of Pressure Die CastingNewsMay.30,2025

-

Precision Casting Manufacturers for High-Quality Metal ComponentsNewsMay.30,2025

-

Key Steps in Aluminum Die Casting ManufacturingNewsMay.30,2025

-

How to Find Affordable Die Casting Components for SaleNewsMay.30,2025

-

General Topics on Casting & Die CastingNewsMay.30,2025

-

Discuss Leading Manufacturers SpecializingNewsMay.30,2025