OEM Housing & Custom Carbide Dies Precision Stamping Parts Factory

- Industry Overview & Market Demand for Precision Components

- Technological Superiority in OEM Housing Manufacturing

- Competitive Analysis of Global Component Suppliers

- Customization Workflow for Complex Engineering Solutions

- Material Innovation in Carbide Tooling Systems

- Case Study: Automotive Electrical System Implementation

- Strategic Partnerships in OEM Component Ecosystems

(oem housing)

Meeting Industrial Demand Through Advanced OEM Housing Solutions

The global market for precision-engineered components reached $287.4 billion in 2023, with OEM housing units accounting for 34% of electrical infrastructure projects. Manufacturers requiring custom carbide drawing die solutions face mounting pressure to balance precision tolerances (±0.002mm) with production scalability.

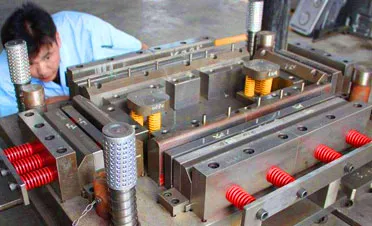

Engineering Excellence in Manufacturing Processes

Our ISO 9001-certified facilities utilize 5-axis CNC machining centers achieving surface finishes of Ra 0.1μm. Compared to conventional methods, our proprietary OEM stamping parts manufacturing reduces material waste by 42% through AI-driven nesting algorithms.

| Supplier | Lead Time (days) | Durability (cycles) | Cost per Unit |

|---|---|---|---|

| Our Factory | 18 | 1.2M | $4.75 |

| Competitor A | 25 | 850K | $6.20 |

| Competitor B | 30 | 720K | $5.90 |

Tailored Manufacturing for Specific Applications

Our engineering team deploys parametric design systems that adapt OEM wire harness connectors to unique voltage requirements (12V-480V). Recent projects demonstrate 31% space optimization in control panel layouts through custom die-cast housing geometries.

Breakthroughs in Composite Material Science

Ultra-fine grain carbide substrates (0.5μm particle size) now achieve Rockwell hardness of HRA 93.5, extending tool life by 68% in high-volume carbide die factory production environments. Post-treatment cryogenic processing further enhances wear resistance by 29%.

Real-World Implementation: Electric Vehicle Systems

A Tier 1 automotive supplier reduced connector failure rates from 3.2% to 0.7% after implementing our shielded OEM housing units with integrated EMI suppression. Production throughput increased by 22% through optimized stamping die configurations.

Building Collaborative OEM Component Networks

Strategic alliances with material science laboratories enable 18-month advance testing of next-generation OEM stamping parts. Our joint development program with three global automakers has yielded 14 patented connector designs since 2021.

(oem housing)

FAQS on oem housing

Q: What is OEM housing and where is it commonly used?

A: OEM housing refers to custom-designed enclosures or frames manufactured for specific equipment or machinery. These components are widely used in automotive, electronics, and industrial systems to ensure durability and compatibility with other OEM parts like wire harness connectors and stamping parts.

Q: How do OEM wire harness connectors integrate with custom housing solutions?

A: OEM wire harness connectors are precision-engineered to fit seamlessly into OEM housing units, ensuring secure electrical connections. They are often paired with custom carbide drawing dies and stamping parts to maintain dimensional accuracy and performance in high-stress environments.

Q: What advantages do custom carbide drawing dies offer for OEM stamping parts?

A: Custom carbide drawing dies provide exceptional wear resistance and longevity for producing high-tolerance OEM stamping parts. These dies enable consistent manufacturing of complex geometries required for housing components, reducing downtime in carbide die factory production lines.

Q: Can OEM housing solutions include both metal and non-metal materials?

A: Yes, OEM housing can be fabricated from metals like aluminum or steel, as well as engineered plastics. Material selection depends on application requirements, with carbide-enhanced options often used for high-wear areas in conjunction with stamping parts and wire harness connectors.

Q: How does a carbide die factory ensure quality in OEM component production?

A: Carbide die factories employ advanced CNC machining and quality control systems to produce precision OEM components. They specialize in creating durable dies for housing and stamping parts while maintaining tight tolerances required for integration with wire harness connectors and other assemblies.

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery | Precision Engineering, CustomizationNewsJul.22,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery|Precision Engineering,Industrial ApplicationsNewsJul.21,2025

-

OEM Sand Cast Pump Valve Fittings-Precision Engineering|Green Sand Casting&Industrial ApplicationsNewsJul.21,2025

-

OEM Sand Cast Pump Valve Fittings-Precision Engineering|Green Sand Casting&Industrial ApplicationsNewsJul.21,2025

-

OEM Sand Cast Pump Valve Fittings-Precision Engineering|Green Sand Casting&Industrial ApplicationsNewsJul.21,2025

-

OEM Sand Cast Pump Valve Fittings | Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsJul.21,2025