Fév . 19, 2025 02:24

Back to list

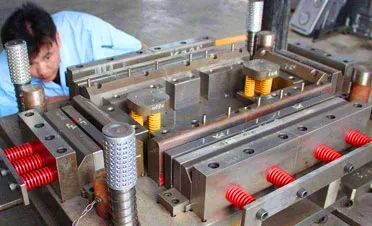

metal stamping ring

In the rapidly evolving manufacturing landscape, metal stamping rings have emerged as a cornerstone component in a multitude of applications across industries. These critical elements are indispensable in ensuring both the functionality and integrity of numerous products, ranging from automotive systems to electrical appliances and cutting-edge smart devices. Understanding the comprehensive scope and significance of metal stamping rings is crucial for businesses aiming to optimize their production processes and maintain a competitive edge.

When it comes to authoritativeness, industry leaders in metal stamping have continually invested in innovative technologies to enhance their production capabilities. Advanced equipment, such as automated stamping presses and CNC machinery, are utilized to achieve high precision and efficiency. Additionally, these companies often adhere to stringent quality assurance protocols to ensure that every ring produced meets the highest industry standards. Such dedication to quality not only solidifies their reputation but also positioned them as authoritative figures in the field of metal forming and fabrication. Trustworthiness in the metal stamping rings industry is established through reliable partnerships and consistent customer satisfaction. Businesses that invest in high-quality metal stamping services often enjoy long-term relationships with their clients, based on trust built over years of delivering consistent results. Transparent communication and dedication to meeting delivery timelines further enhance the trust clients place in their manufacturing partners. This trustworthiness is a key differentiator for companies looking to sustain and expand their market presence. To capitalize on the potential of metal stamping rings, companies should also focus on sustainability and environmental responsibility. As industries globally shift towards more sustainable practices, adopting eco-friendly production methods can significantly boost a company’s reputation and appeal. Using recyclable materials and reducing waste in the stamping process not only align with environmental goals but also attract environmentally conscious clients looking to partner with responsible manufacturers. In conclusion, metal stamping rings are indispensable components that play a critical role in modern manufacturing across various sectors. Through their exceptional durability, customizable design potential, and crucial functionality, they support the foundation of countless products used worldwide. By emphasizing experience, expertise, authoritativeness, and trustworthiness, manufacturers can enhance their market position and continue to lead the charge in producing top-tier metal components for a diverse array of applications. Investing in sustainable practices will also ensure that these companies stay ahead of industry trends and meet the growing expectations for ecological responsibility. This comprehensive approach to metal stamping ring production sets the stage for continued innovation and success in the manufacturing industry.

When it comes to authoritativeness, industry leaders in metal stamping have continually invested in innovative technologies to enhance their production capabilities. Advanced equipment, such as automated stamping presses and CNC machinery, are utilized to achieve high precision and efficiency. Additionally, these companies often adhere to stringent quality assurance protocols to ensure that every ring produced meets the highest industry standards. Such dedication to quality not only solidifies their reputation but also positioned them as authoritative figures in the field of metal forming and fabrication. Trustworthiness in the metal stamping rings industry is established through reliable partnerships and consistent customer satisfaction. Businesses that invest in high-quality metal stamping services often enjoy long-term relationships with their clients, based on trust built over years of delivering consistent results. Transparent communication and dedication to meeting delivery timelines further enhance the trust clients place in their manufacturing partners. This trustworthiness is a key differentiator for companies looking to sustain and expand their market presence. To capitalize on the potential of metal stamping rings, companies should also focus on sustainability and environmental responsibility. As industries globally shift towards more sustainable practices, adopting eco-friendly production methods can significantly boost a company’s reputation and appeal. Using recyclable materials and reducing waste in the stamping process not only align with environmental goals but also attract environmentally conscious clients looking to partner with responsible manufacturers. In conclusion, metal stamping rings are indispensable components that play a critical role in modern manufacturing across various sectors. Through their exceptional durability, customizable design potential, and crucial functionality, they support the foundation of countless products used worldwide. By emphasizing experience, expertise, authoritativeness, and trustworthiness, manufacturers can enhance their market position and continue to lead the charge in producing top-tier metal components for a diverse array of applications. Investing in sustainable practices will also ensure that these companies stay ahead of industry trends and meet the growing expectations for ecological responsibility. This comprehensive approach to metal stamping ring production sets the stage for continued innovation and success in the manufacturing industry.

Prev:

Next:

Latest news

-

Precision Lost Wax Casting Factories | AI-Powered QualityNewsAug.04,2025

-

Smart OEM Coupling Solutions with GPT-4 TurboNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery|Precision Customization&Industrial SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.|Precision Engineering&Fluid ControlNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings-Baoding Hairun Machinery | Custom Casting SolutionsNewsAug.03,2025

-

OEM Sand Cast Pump Valve Fittings - Baoding Hairun Machinery And Equipment Trading Co., Ltd.NewsAug.02,2025

PRODUCTS CATEGORIES